Alkyl-substituted disilane and preparation method thereof

A disilane and alkyl technology, which is applied in the field of alkyl-substituted disilane and its preparation, can solve the problem of not being able to meet the requirements of long-term use under harsh conditions such as high temperature, acid and alkali, long-term use, and the increase in the viscosity of silicone oil, etc. problems, to achieve the effect of controllable product structure, obvious social and economic benefits, and outstanding heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Grignard reaction prepares the method for phenyl-substituted disilane, main steps are as follows:

[0047] a. Raw materials and proportioning: Take high-boiling point chlorosilane waste liquid, bromobenzene, and magnesium powder as raw materials; take magnesium powder and bromobenzene according to the molar ratio of magnesium powder: bromobenzene is 1.2:1; use high-boiling point chlorosilane waste liquid The molar ratio of chlorine atom to Grignard reagent is 1:1.1 to take high-boiling point chlorosilane waste liquid; the content of chlorine atom in high-boiling point chlorosilane waste liquid is 13mol / L through acid-base titration;

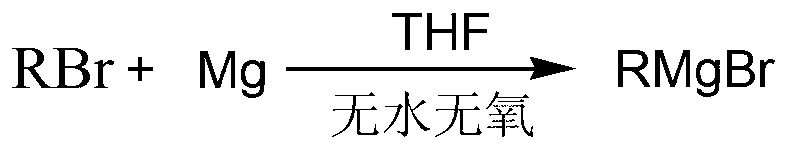

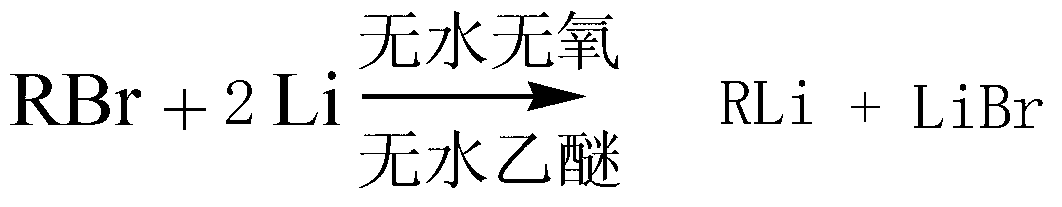

[0048] b. Preparation of Grignard reagent: Add 1.2g (0.050mol) of magnesium powder into a reactor equipped with a constant pressure dropping funnel, vacuumize the reactor and pass nitrogen three times to remove oxygen and water in the reactor; Add 2ml ether and 40μg catalytic amount of iodine into the reactor, add bromobenzene (6.44g, 40.7...

Embodiment 2

[0054] Grignard reaction prepares the method for octyl-substituted disilane, and main steps are as follows:

[0055] a. Raw materials and raw material ratio: Take high-boiling point chlorosilane waste liquid, 1-bromooctane, and magnesium powder as raw materials; take magnesium powder and 1-bromooctane at a molar ratio of 1.2:1 for magnesium powder: 1-bromooctane Chlorine atoms in high-boiling point chlorosilane waste liquid: Grignard reagent is 1:1.1 molar ratio to take high-boiling point chlorosilane waste liquid, and the content of chlorine atoms in high-boiling point chlorosilane waste liquid is 13mol / L through acid-base titration ;

[0056] b. Preparation of Grignard reagent: Add 1.2g (0.050mol) of magnesium powder into a reactor equipped with a constant pressure dropping funnel, vacuumize the reactor and pass nitrogen three times to remove oxygen and water in the reactor; Add 2ml ether and 40μg catalytic amount of iodine into the reactor, add 1-bromooctane (7.85g, 40.7mm...

Embodiment 3

[0062] Grignard reaction prepares the method for decyl-substituted disilane, main steps are as follows:

[0063] a. Raw materials and proportioning: Take high-boiling chlorosilane waste liquid, 1-bromodecane, and magnesium powder as raw materials; take magnesium powder and 1-bromodecane at a molar ratio of 1.2:1 for magnesium powder: 1-bromodecane ;According to the high-boiling point chlorosilane waste liquid chlorine atom: Grignard reagent is 1:1.1 molar ratio to get the high-boiling point chlorosilane waste liquid, the content of chlorine atoms in the high-boiling point chlorosilane waste liquid is 13mol / L through acid-base titration;

[0064]b. Preparation of Grignard reagent: Add 1.2g (0.050mol) of magnesium powder into a reactor equipped with a constant pressure dropping funnel, vacuumize the reactor and pass nitrogen three times to remove oxygen and water in the reactor; Add 2ml ether and 40μg catalytic amount of iodine into the reactor, add 1-bromodecane (8.99g, 40.7mmo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com