Silicon oxide/titanium oxide composite mesoporous flexible non-woven fiber membrane, and preparation method and application thereof

A composite mesoporous and non-woven fiber technology, applied in the direction of alkali metal oxides/hydroxides, chemical instruments and methods, silicon compounds, etc., can solve the problems of poor mechanical properties of fiber membranes, limited application fields, and fragility. Achieve the effects of easy bending, large specific surface area, and good adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

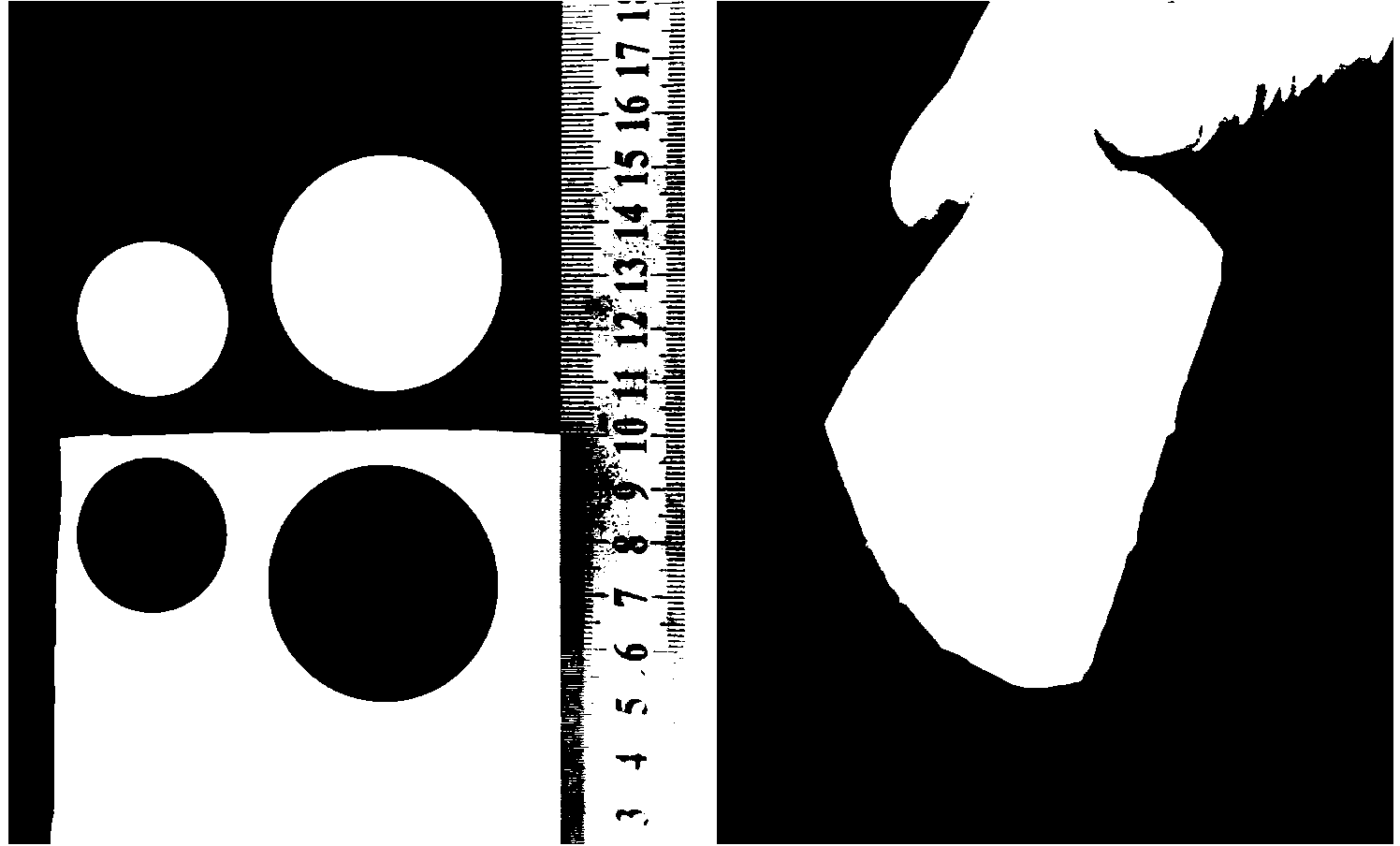

Image

Examples

Embodiment 1

[0030]Dissolve 0.2g of polyoxyethylene (Mw=1,000,000) in a mixed solution of 0.5g of water and 3.65g of absolute ethanol, add 2g of 20wt% titanium trichloride aqueous solution (add 0.16g, mass fraction of 37% concentrated hydrochloric acid stabilized titanium Salt), then add 1.85g of cetyltrimethylammonium bromide, stir well to dissolve. Slowly add 4 g of ethyl orthosilicate, vigorously stir and hydrolyze for 1 hour, place in an electrospinning spinneret with an inner diameter of 0.8 mm, and use a syringe pump to control the flow rate of the spinning solution to 1 mL / h. A positive voltage of 12kV is applied to the spinneret, and a negative voltage of 12kV is applied to the aluminum foil as the receiving electrode.

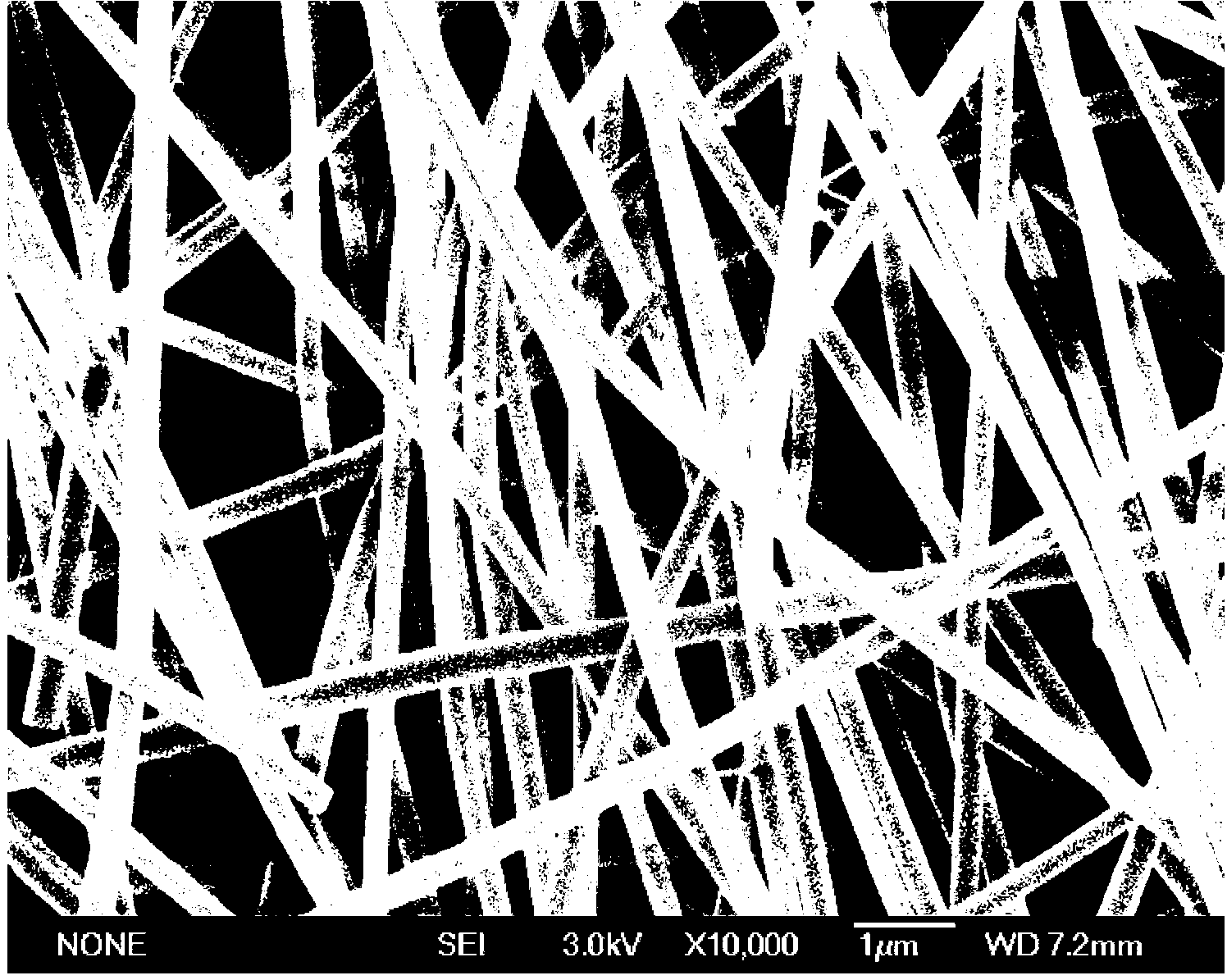

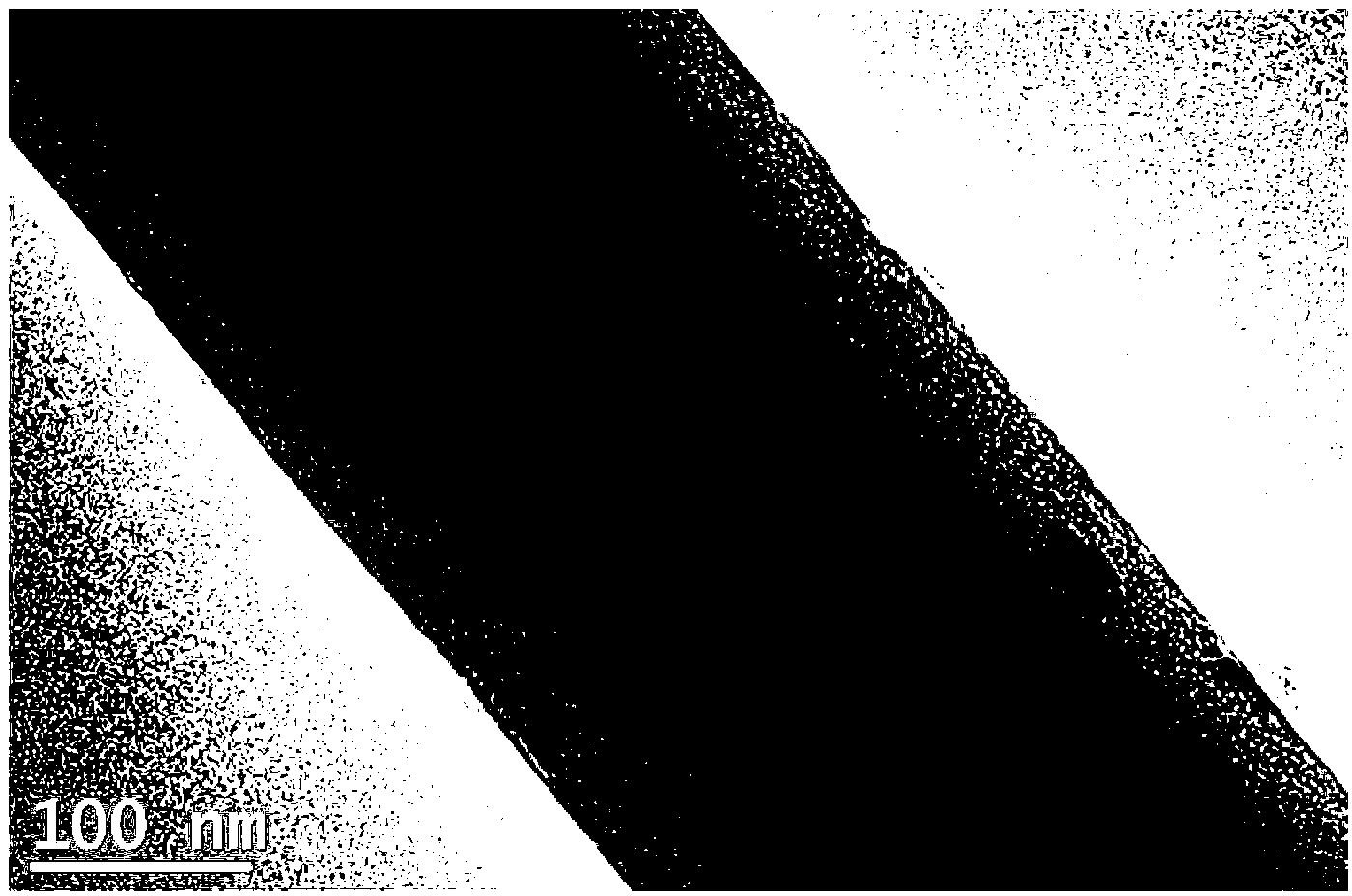

[0031] After the electrospinning process, a layer of inorganic-organic composite fiber membrane can be obtained on the receiving electrode. Put this product together with the receiving plate in the muffle furnace, calcined to 500 ° C for 2 hours, and after cooling...

Embodiment 2

[0033] Dissolve 0.7g of polyvinyl alcohol (Mw=90,000) in a mixed solvent of 6g of water and 1g of ethanol in a water bath at 90°C. Add 1g of 10wt% titanium tetrachloride solution (stabilized with 10wt% hydrochloric acid aqueous solution), then add 1.5g of hexadecyltrimethylammonium chloride, fully stir to dissolve and mix. Slowly add 3 g of tetraethyl orthosilicate, stir vigorously and hydrolyze for 6 hours, place in an electrospinning spinneret, use aluminum foil as a receiving electrode, and ground it.

[0034] After the electrospinning process, a layer of inorganic-organic composite fiber membrane can be obtained on the receiving electrode. Put this product together with the receiving plate in the muffle furnace, calcined to 750 ° C for 4 hours, and after cooling to room temperature, the silicon oxide / titanium oxide composite mesoporous flexible non-woven fiber membrane can be removed from the receiving plate , the specific surface area of the prepared silica / titanium ox...

Embodiment 3

[0036] Dissolve 0.4g of polyoxyethylene (Mw=300,000) in a mixed solution of 0.5g of water and 3.65% of absolute ethanol, add 2g of 40wt% titanium sulfate solution (stabilized with 20wt% sulfuric acid aqueous solution), and then add 2g of octadecyltrimethyl ammonium bromide, stirred thoroughly to dissolve after mixing. Slowly add 4g of methyl orthosilicate, vigorously stir and hydrolyze for 0.5 hours, then in the electrospinning spinneret, the inner diameter of the spinneret is 0.8mm, and the flow rate of the spinning solution is controlled by a syringe pump to 0.8mL / h. A positive voltage of 15kV is applied to the spinneret, and a negative voltage of 10kV is applied to the aluminum foil as the receiving electrode.

[0037] After the electrospinning process, a layer of inorganic-organic composite fiber membrane can be obtained on the receiving electrode. Put this product together with the receiving plate in the muffle furnace, calcined to 400 ° C for 2 hours, and after cooling ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com