Micro-pore polarity induction absorbent for regeneration treatment on electric power oil and preparation method of micro-pore polarity induction absorbent

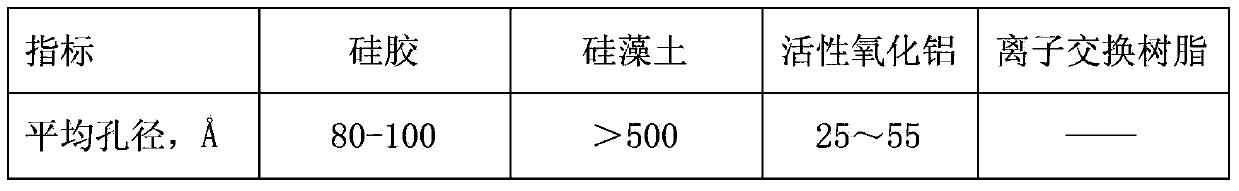

A technology for power oil and adsorbent, which is applied in the field of power oil regeneration treatment of microporous polarity-inducing adsorbent and its preparation, can solve the problems of limited effect, limited types of deterioration products, large pore size of adsorption medium, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

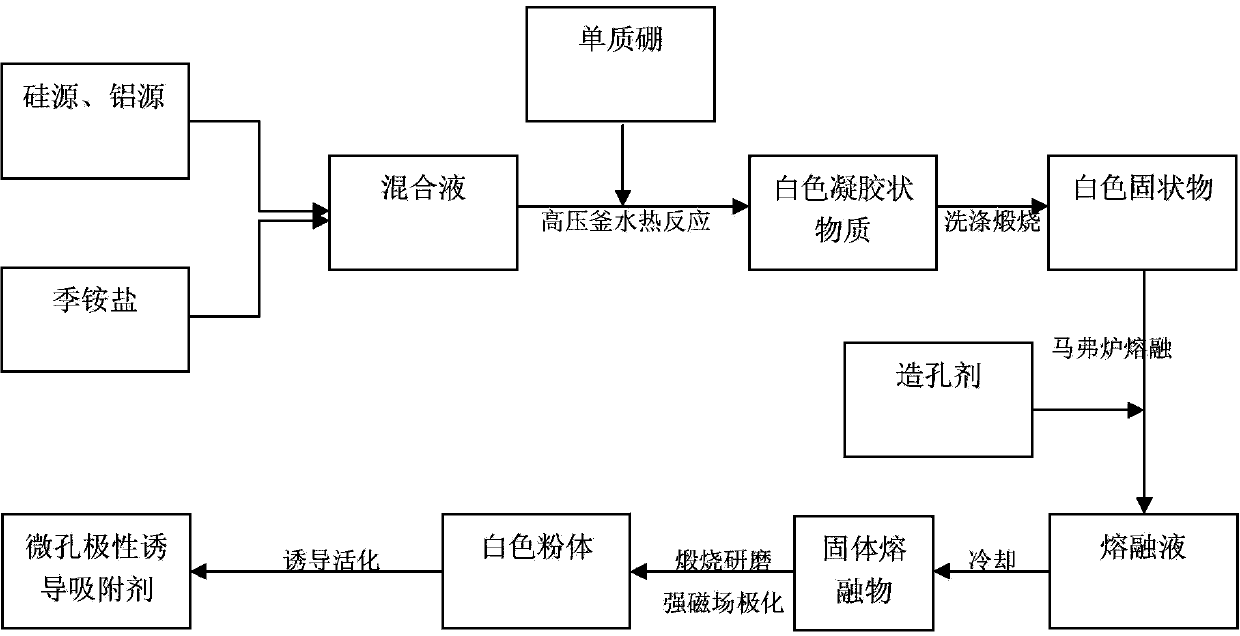

Method used

Image

Examples

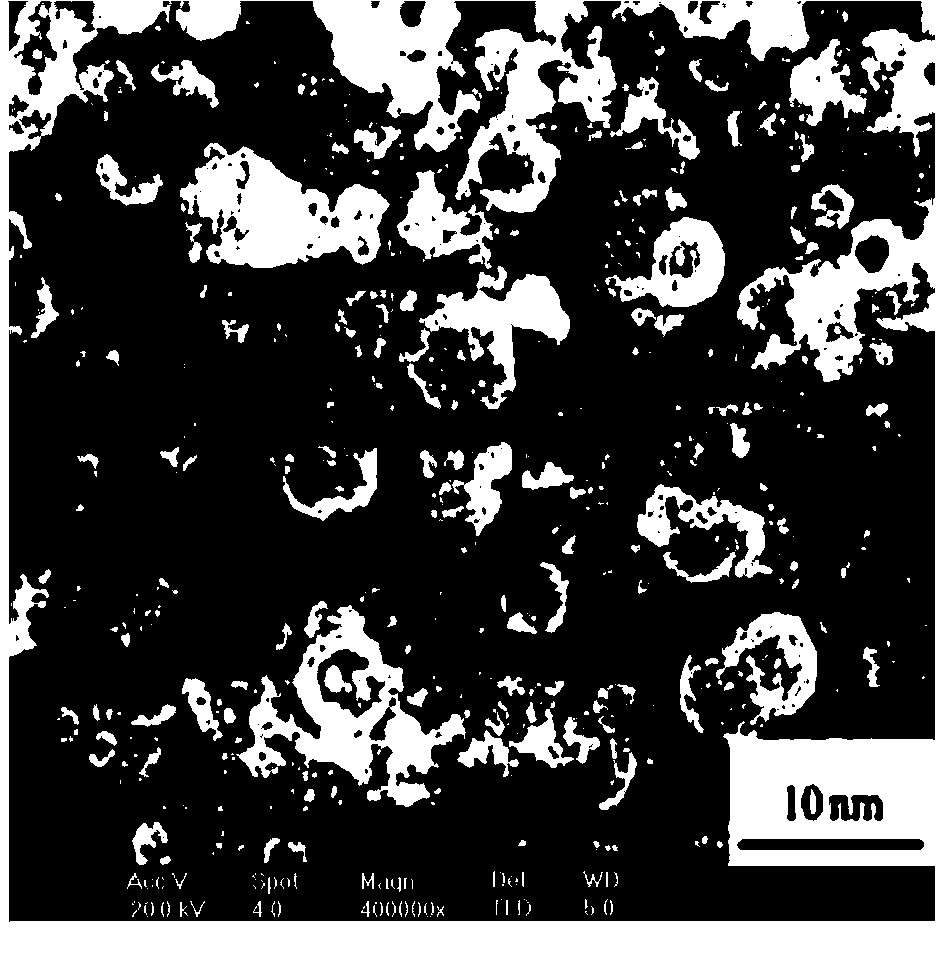

Embodiment 1

[0044] The cetyltrimethylammonium bromide of 36.4g is dissolved in the aqueous ethanol solution of 300ml (Wt 乙醇 =20%), adjust the pH value of the solution to 11 with ammonia water to obtain an alkaline solution; take 57.6g of SiO 2 2H 2 O and 85.8g of Al(OH) 3 Dissolve in the above alkaline solution in a water bath at 60°C, stir for 10 hours, and the speed of the stirring paddle is 800 r / min; after the solution is evenly stirred, add 0.5 g of elemental boron, and continue stirring for 10 hours. After the boron doping is uniform, the solution is moved into a stainless steel autoclave lined with polytetrafluoroethylene, distilled water is added, the water level is controlled at 80% of the height of the reactor, and the constant temperature of the blast drying oven is controlled at 150°C, and the hydrothermal reaction is carried out for 18 hours , A white gel-like substance was obtained after the reaction. Wash the white gel-like substance and place it in a tubular heating fur...

Embodiment 2

[0050] 48.2g of cetyltrimethylammonium chloride was dissolved in 400ml of deionized water, and the pH value of the solution was adjusted to 10 with sodium bicarbonate to obtain an alkaline solution; 70g of tetraethyl orthosilicate and 51.4g of Al 2 o 3 Dissolve in the above alkaline solution in a water bath at 80°C and stir for 15 hours at a stirring speed of 1200r / min; add 0.68g of elemental boron to the solution and continue stirring for 10 hours; transfer the mixed solution into a high-pressure reactor, Control the constant temperature of the blast drying oven at 180° C., and carry out the hydrothermal reaction for 24 hours. After the reaction, a white gel-like substance is obtained. The white gel was repeatedly washed with ethanol and deionized water, and then calcined in a muffle furnace at 800°C for 6 hours to obtain a white blocky solid. Control the temperature of the muffle furnace at 1700°C to melt the white blocky solid. Add 41g of graphite to the liquid and dispers...

Embodiment 3

[0055] Dissolve 28.5g of cetyltrimethylammonium bromide and 19.4g of octadecyltrimethylammonium chloride in 500ml of deionized water, adjust the pH value of the solution to 8 with glacial acetic acid; add 170g of kaolin, at 70°C Stir in a water bath for 24 hours, the stirring speed is controlled at 1500r / min; add 0.8g elemental boron to the mixed solution, and continue to stir for 10 hours; move the boron-doped mixed solution into the reaction kettle, control the temperature at 220°C, and adjust the water volume in the reaction kettle To normal, carry out hydrothermal reaction for 36h; wash the white gel after hydrothermal reaction with absolute ethanol and deionized water successively, control the temperature of the tubular heating furnace at 800°C, and calcinate the white gel for 10h, The obtained white solid calcined product is then heated and melted in a muffle furnace at 1600°C, and 37g of graphite is added to the molten liquid to make holes. Carry out secondary calcinati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com