Preparation method of light-weight wall brick

A lightweight wall, mass ratio technology, applied in the field of building filling materials, can solve the problems of complex preparation, high shrinkage, low strength, etc., and achieve the effects of improving mechanical strength, simple preparation method, and improving flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

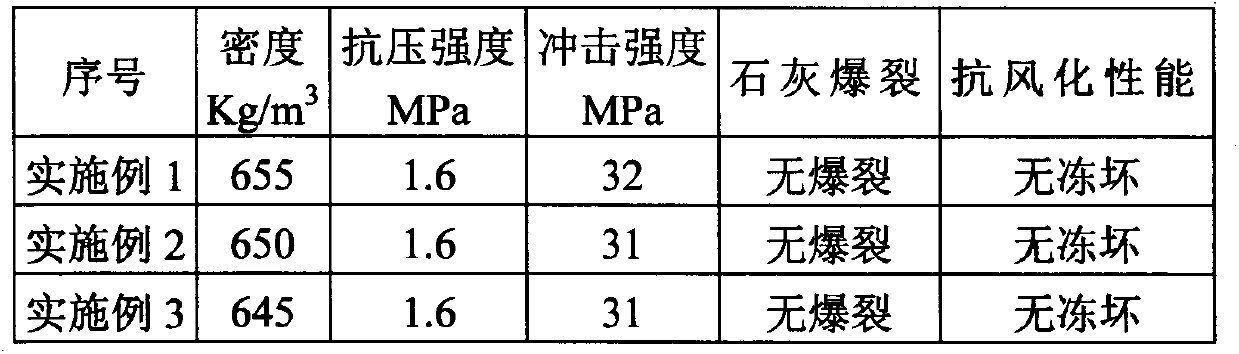

Examples

Synthetic example 1

[0034] Synthesis Example 1 Surface Treatment of Expandable Hollow Polymethylmethacrylate Microspheres

[0035] Mix expandable hollow polymethyl methacrylate microspheres, deionized water, and methacrylic acid in a mass ratio of 1:100:25, place the mixed solution on a magnetic stirrer and heat at 45°C for 30 minutes , and then subjected to ultrasonic vibration treatment for 15 minutes, placed in a vacuum oven at a temperature of 105° C. after the treatment, and baked for 0.5 hour to obtain surface-treated expandable hollow polymethylmethacrylate microspheres.

Synthetic example 2

[0036] Preparation of Synthetic Example 2 Cyanate Resin Epoxy Resin Copolymer Fiber

[0037] Add bisphenol A type cyanate resin monomer and bisphenol A type epoxy resin monomer in the ratio of 1:20 by mass ratio in the container, prepolymerize at 95 ℃ for 15 minutes to obtain prepolymer; then prepolymerize The polymer is dissolved in acetone to form a spinning solution with a concentration of 20%; the fiber material is prepared by conventional electrospinning, and its diameter is 0.09-0.14 microns;

[0038] The process parameters of electrospinning are: voltage 1-50 kV, receiving distance 1-50 cm, solution flow rate 0.01-20 mL / h.

Synthetic example 3

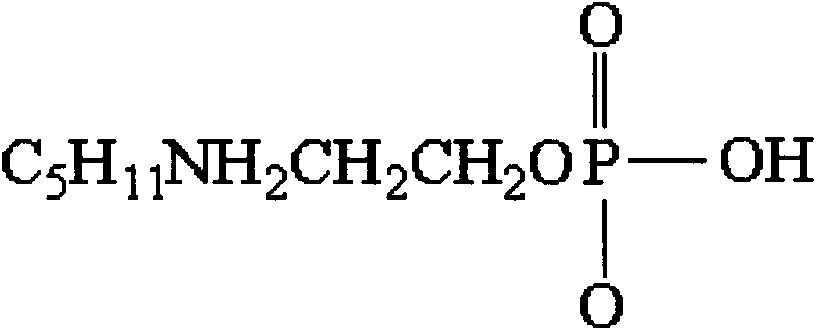

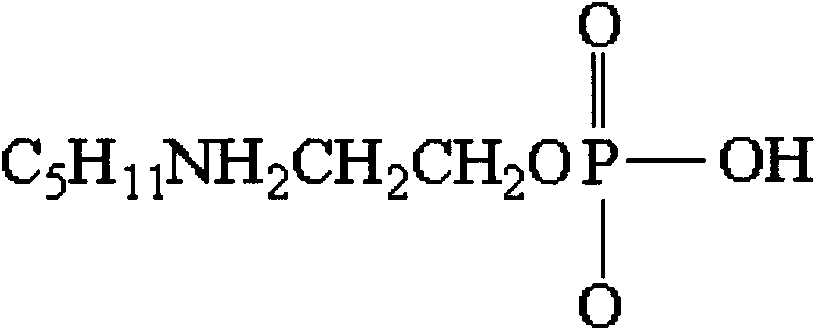

[0039] Synthesis of Synthesis Example 3 Phosphate Ester

[0040] Add 12mL of n-pentane bromide, 8ml of diethanolamine, 30ml of absolute ethanol and 4g of potassium silanolate to the three-necked flask, reflux and stir for 3 hours, cool, and filter to obtain the liquid; add 1.5ml of 85% phosphoric acid, 50ml of Acetone and 2g of phosphorus pentoxide were heated to 60°C, stirred and reacted for 2 hours, and the acetone was distilled off to obtain a light yellow liquid, which was phosphoric acid ester.

[0041] Synthesis example Synthesis of 4-terminal hydroxyl polysiloxane

[0042] Under the protection of nitrogen, add 20g of 3-glycidyl etheroxypropyl trimethoxysilane and 2g of tetramethyltetravinyl cyclotetrasiloxane into 40g of distilled water, mix well, then add 0.001g of tetramethyl sodium hydroxide , heat up to 60°C, stir and react for 30 minutes, then add 6g of hydroxy silicone oil, heat to 80°C, react for 20 minutes, cool down naturally, let stand to separate layers, tak...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com