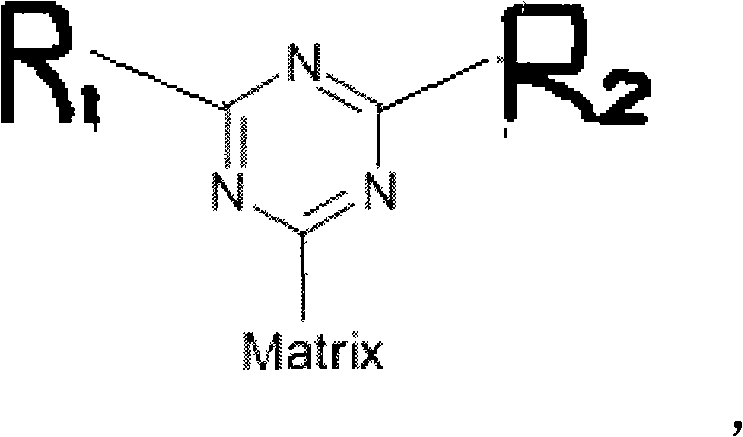

Antibody separating and purifying medium and preparation method thereof

A technology of separation, purification and medium, applied in the field of biological separation materials, to achieve the effect of improving selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

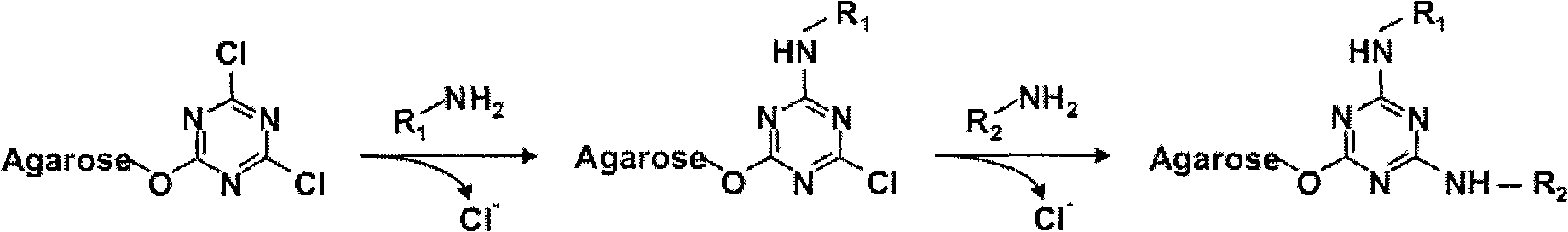

[0020]

[0021] As shown in the above chemical reaction simple formula, first use s-triazine to activate the agarose gel microspheres. Dissolve 10 g of s-triazine (sym-triazine, colorless crystals, melting point 86°C, boiling point 114°C, CAS4719-04-4) in 100ml of dichloromethane, filter, use a rotary evaporator to evaporate the solvent, and remove the residual solid Redissolve in 100ml of acetone and cool to -5°C in an ice-salt bath. Take 10 g of agarose gel microspheres (cross-linking degree 6%, average particle diameter 90 μm) and add to 50 ml of NaOH solution, stir at room temperature for 15 minutes, and filter to remove NaOH solution. The gel was resuspended in cold NaOH solution at 4°C and cooled to 0°C in an ice-salt bath. To this solution was added 20 ml of a cold s-triazine / acetone solution, and the stirring was continued for 70 minutes on an ice bath and 30 minutes at room temperature. Filter, wash with 50ml of acetic acid aqueous solution (1:1 volume ratio) and...

Embodiment 2

[0023] Mix 8.5 volumes of 0.2M K2HPO4 solution with 1.5 volumes of 0.2M KH2PO4 solution to make the coupling buffer. Take 10 g of the s-triazine-activated sepharose microspheres in Example 1 and suspend them in 10 ml of coupling buffer. Then, 4-(2-aminoethyl)-pyridine was added at a ratio of 10 mg / ml as the small molecule affinity ligand of the antibody. Stirring (or shaking, shaking) was continued at room temperature for 24 hours. Wash with coupling buffer until five absorption peaks at 293nm wavelength. The ligand density of the obtained medium was 130 μmol / ml. It was stored in sodium acetate solution (0.2M, pH 5.4) containing 0.02% sodium azide (w / v) until use.

Embodiment 3

[0025] Mix 8.5 volumes of 0.2M K2HPO4 solution with 1.5 volumes of 0.2M KH2PO4 solution to make the coupling buffer. Take 10 g of the s-triazine-activated sepharose microspheres in Example 1 and suspend them in 10 ml of coupling buffer. Then, 4-(2-hydroxyethyl)-pyridine was added at a ratio of 20 mg / ml as the small-molecule affinity ligand of the antibody. Stirring (or shaking, shaking) was continued at room temperature for 24 hours. Wash with coupling buffer until five absorption peaks at 293nm wavelength. The ligand density of the obtained medium was 150 μmol / ml. It was stored in sodium acetate solution (0.2M, pH 5.4) containing 0.02% sodium azide (w / v) until use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com