Quasi homogeneous magnetic nano-particle supported palladium catalyst and preparation method

A technology of magnetic nanoparticles and magnetic nanocarriers, which is applied in the field of palladium catalysts supported by ferroferric oxide magnetic nanoparticles wrapped in silica gel and its preparation, to achieve the effects of rapid separation and recovery, basically unchanged activity and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The preparation method of magnetic nanoparticle supported palladium catalyst is as follows:

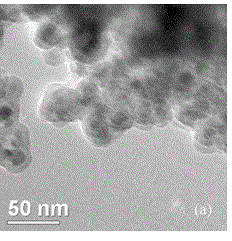

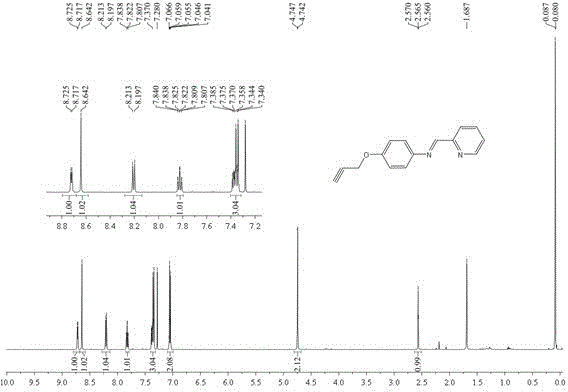

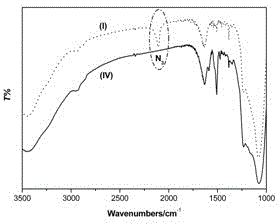

[0036] (1) Preparation of nano-ferric oxide magnetic particles coated with silica gel: Take 11.0g of ferric chloride and 4.0g of ferrous chloride and dissolve them in 250mL of deionized water under nitrogen atmosphere at 85°C with vigorous stirring, and then adjust them with concentrated ammonia water When the pH value reaches 9, the stirring is continued for 4 hours, and the precipitate is washed with deionized water to neutrality to obtain black ferric oxide particles (8-12nm). Take 2.0g of the above iron ferric oxide particles and ultrasonicate at room temperature for 30min, disperse in 400mL ethanol, then add 12mL concentrated ammonia water and 4.0mL tetraethyl orthosilicate, stir and react for 24h, the black precipitate is magnetically separated and washed with ethanol several times After vacuum drying, the silica gel-wrapped ferroferric oxide magnetic nanoparticles (20-30...

Embodiment 2

[0044] Only the method of loading nano-palladium on magnetic nanoparticles in Step 5 of Example 1 is changed as follows, and other steps are consistent with Example 1.

[0045] Get 34mg palladium chloride and 13mg sodium chloride in 2mL methanol room temperature reaction 24h and make brown red sodium chloropalladate (Na 2 PD 2 Cl 6 ) in methanol. Add 0.5 g of the magnetic particles prepared in step 4 and 18 mL of methanol, and then react at 60° C. for 24 h. After that, 110 mg of sodium acetate was added and stirred at room temperature for 90 min. After the reaction is completed, the palladium catalyst is obtained by magnetic separation, washed with methanol, water and acetone in sequence, and vacuum-dried for use as Pd Cat.2. Palladium content: Pd 2.16% (ICP-AES).

Embodiment 3

[0047] Only the method of loading nano-palladium on magnetic nanoparticles in Step 5 of Example 1 is changed as follows, and other steps are consistent with Example 1.

[0048] Get 17mg palladium chloride and 6mg sodium chloride in 1mL methanol room temperature reaction 24h and make brown red sodium chloropalladate (Na 2 PD 2 Cl 6 ) in methanol. Add 1.0 g of magnetic particles prepared in step 4 and 9 mL of methanol, and then react at 60° C. for 24 h. After that, 56 mg of sodium acetate was added and stirred at room temperature for 1 h. After the reaction is completed, the palladium catalyst is obtained by magnetic separation, washed with methanol, water and acetone in sequence, and vacuum-dried for use as Pd Cat.3. Palladium content: Pd 0.67% (ICP-AES).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com