Sugarcane fertilizer additive and preparation method thereof

A fertilizer additive and sugarcane technology, applied in the direction of fertilizer mixture, fertilization device, application, etc., can solve the problems of soil compaction, structural deterioration, less sugarcane absorption and utilization, and low fertilizer utilization rate, so as to improve stress resistance and improve Drought resistance and stress resistance, the effect of sugarcane root development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

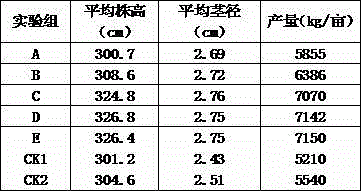

Image

Examples

Embodiment 1

[0044] 4 parts by weight of humic acid and 1 part by weight of cerium trichloride, 1 part by weight of lanthanum trichloride, 1 part by weight of praseodymium trichloride, 1 part by weight of neodymium trichloride, 1 part by weight of europium trichloride and 1 part by weight of trichloride Add samarium chloride into the reaction kettle, add an appropriate amount of water, and stir and react at 85-95°C for 1-3h; transfer the materials in the reaction kettle to a homogeneous kettle, add 3 parts by weight of ferrous sulfate, 1.2 parts by weight of manganese sulfate, 0.6 parts by weight of zinc acetate, 0.6 parts by weight of copper sulfate, 0.3 parts by weight of boric acid, 0.3 parts by weight of sodium molybdate, stirred for 20 to 30 minutes, added 3 parts by weight of polyacrylic acid resin, 4 parts by weight of polyacrylamide and 15 parts by weight of organic matter, and stirred 30-60 minutes, drying, pulverizing, and passing through a 80-mesh sieve to obtain a sugarcane fert...

Embodiment 2

[0046] Add 3 parts of humic acid, 1.25 parts of cerium trichloride, 1.25 parts of lanthanum trichloride, 1.25 parts of praseodymium trichloride, 1.25 parts of neodymium trichloride, 1.25 parts of europium trichloride and 1.25 parts of samarium trichloride into the reaction kettle , add an appropriate amount of water, and stir and react at 85-95°C for 1-3 hours; transfer the materials in the reactor to a homogeneous kettle, add 4 parts of iron sulfate, 1.2 parts of manganese sulfate, 0.6 parts of zinc naphthenate, and 0.6 parts of cycloalkanoate Copper alkanoate, 0.3 parts of boric acid, 0.3 parts of potassium molybdate, stirring for 20-30 minutes, adding 8 parts of polyethylene-maleic anhydride resin, 8 parts of sodium polyacrylate and 12 parts of organic matter, stirring for 30-60 minutes, drying, crushing, Pass through an 80-mesh sieve to obtain the sugarcane fertilizer additive.

Embodiment 3

[0048] Add 6 parts of humic acid, 2 parts of cerium oxide, 2 parts of lanthanum oxide, 2 parts of praseodymium oxide, 2 parts of neodymium oxide, 2 parts of europium oxide and 2 parts of samarium oxide into the reaction kettle, add an appropriate amount of water, and stir the reaction at 85-95 °C 1~3h; Transfer the materials in the reaction kettle to the homogeneous kettle, add 5.4 parts of ferric chloride, 1.8 parts of manganese sulfate, 1 part of zinc sulfate, 1 part of copper naphthenate, 0.4 parts of borax, 0.4 parts of ammonium molybdate , stirred for 20 to 30 minutes, added 10 parts of ethylene-vinyl acetate copolymer, 10 parts of gum arabic and 8 parts by weight of organic matter, stirred for 30 minutes, dried, pulverized, and passed through a 80-mesh sieve to obtain a sugarcane fertilizer additive.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com