Silica gel monolithic column modified by cyclodextrin modified nanocrystalline iron oxide

A silica monolithic column and nano iron oxide technology, applied in the preparation of organic compounds, organic chemistry, other chemical processes, etc., to achieve the effect of good reproducibility, improved separation effect, stable property and structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

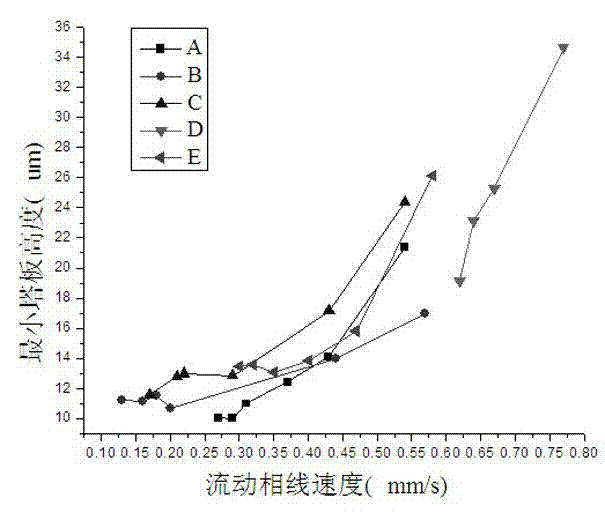

[0028] Prepare the contents of polyethylene glycol, urea, tetramethoxysilane, and γ-glycidyl etheroxypropyltrimethoxysilane according to the following data:

[0029] Column A: 200 mg polyethylene glycol, 310 mg urea.

[0030] Column B: 180 mg polyethylene glycol, 310 mg urea.

[0031] Column C: 160 mg polyethylene glycol, 370 mg urea.

[0032] Column D: 160 mg polyethylene glycol, 250 mg urea.

[0033] Column E: 160 mg polyethylene glycol, 310 mg urea.

[0034] It was dissolved in 2.0 mL of 0.01 mol / L acetic acid aqueous solution, and then 720 μL of TMOS and 800 μL of γ-GPTMS were added dropwise, and reacted in an ice bath at 0°C for 1 hour to obtain a transparent and uniform sol mixture. Use a syringe to manually inject the pretreated capillary to an appropriate length, seal both ends of the capillary, react in a water bath at 55°C for 12 hours, and rinse with secondary water and methanol respectively. Using acetonitrile:triethylamine phosphate buffer (5mmol / L, pH 7.0) as...

Embodiment 2

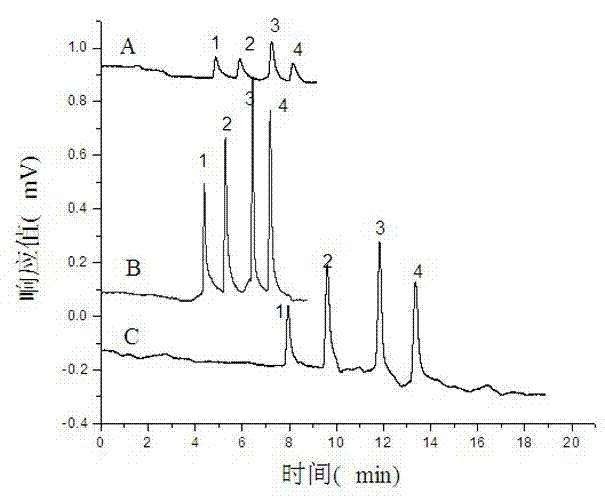

[0036] Cyclodextrin modified nano iron oxide is added according to the following data:

[0037] Column A: 6mg cyclodextrin modified nano iron oxide.

[0038] Column B: 4 mg cyclodextrin-modified nano iron oxide.

[0039] Column C: 2 mg of cyclodextrin-modified nano iron oxide.

[0040] Dissolve it in 1mL of mixed solution (0.1M0.1M sodium hydroxide solution:methanol: 1:1, volume ratio), sonicate for 5min, inject it into the prepared silica gel monolithic column, and place it in a water bath at 65°C for 12h. Rinse with secondary water and methanol respectively. Acetonitrile: triethylamine phosphate buffer (5mmol / L, pH 3.0) was used as the mobile phase of 90:10, the separation voltage was -20kV, the detection wavelength was 214nm, the flow rate was 0.1mL / min, and the pressure was 0.8MPa.

Embodiment 3

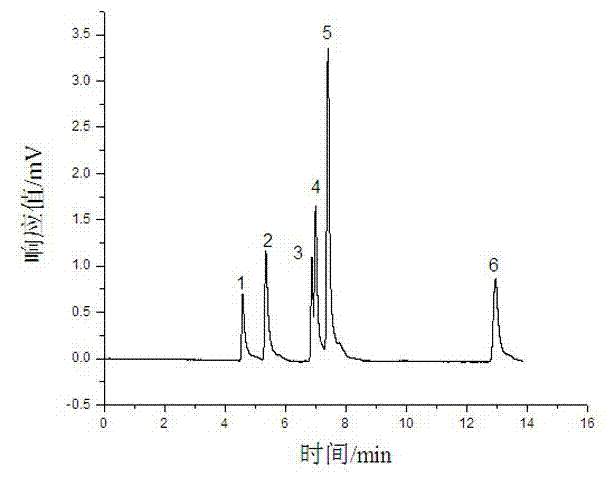

[0042] Cyclodextrin-modified nano-iron oxide-modified silica monolithic column for separation of phenolic compounds.

[0043] Apply the cyclodextrin-modified nano-iron oxide-modified silica monolithic column of the present invention (inner diameter 75 μm, total length 55 cm, effective length 35 cm), acetonitrile: triethylamine phosphate buffer (pH 3.0, 5 mmol / L) with a flow rate of 98:2 Phase, separation voltage -20kV, detection wavelength 214nm, flow rate 0.1mL / min, pressure 0.8MPa, using toluene as a marker, such as image 3 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com