Precious metal-titanium dioxide nanocomposite particle preparation method

A nano-composite particle, titanium dioxide technology, applied in chemical instruments and methods, catalyst activation/preparation, metal/metal oxide/metal hydroxide catalysts, etc., can solve the loss of metal salts, affect catalyst performance, and use poor stability. and other problems, to achieve the effect of improving utilization efficiency and high visible light catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

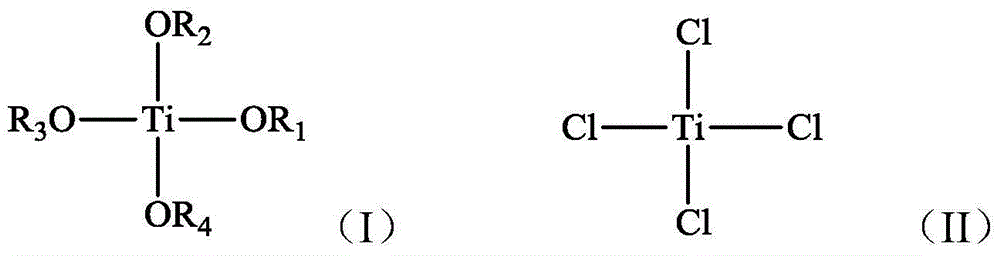

Method used

Image

Examples

Embodiment 1

[0043] The emulsifier is a block copolymer of butene-ethylene copolymer as the hydrophobic segment and polyoxyethylene as the hydrophilic segment [referred to as P(E / B)-PEO]. Weigh 1g and dissolve it in 500g Isopar M (C12~C16 a mixture of alkanes, Exxon Mobil), to obtain an emulsifier solution. The preparation method of this block copolymer sees literature [Schlaad H, Kukula H, Runloff J, Below I.Macromolecules, 2001,34,4302-4304.Thomas A, Schlaad H, Smarsly B, Antonietti M.Langmuir, 2003,19 ,4455-4459.]

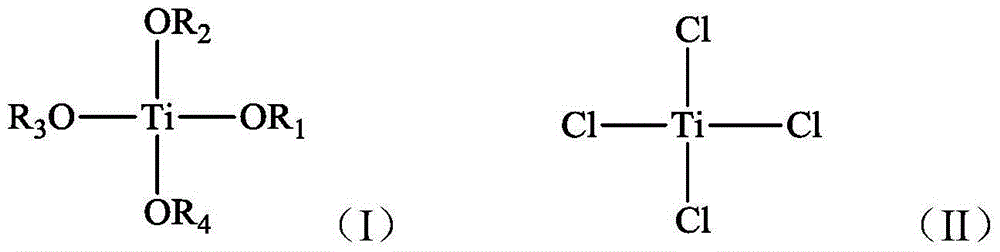

[0044] 2.5g chloroauric acid is dissolved in the polar solvent that 20 grams of dimethyl sulfoxides and 6.3 grams of water form, obtains gold salt solution, gold salt solution is joined in above-mentioned emulsifier solution, with ultrasonic wave above-mentioned mixed solution is dispersed, A stable inverse miniemulsion was obtained.

[0045] At 85° C., 20 g of tetraethyl titanate was added to the above inverse miniemulsion, the temperature was raised to 100° C., and the r...

Embodiment 2

[0049] The emulsifier was SPAN80, weighed 79.5g, and dissolved in 795g of cyclohexane to obtain an emulsifier solution.

[0050] 5g of chloroplatinic acid was dissolved in 53 grams of water to obtain a platinum salt solution. The platinum salt solution was added to the emulsifier solution, and the mixed solution was dispersed by ultrasonic waves to obtain a stable inverse miniemulsion.

[0051] At 30° C., 100 g of tetrabutyl titanate was added to the inverse miniemulsion, the temperature was raised to 60° C., and the reaction was carried out for 10 hours to obtain a dispersion containing platinum salt-titanium dioxide nanocomposite particles.

[0052] Add 56 g of tetramethylethylenediamine to the above dispersion containing platinum salt-titanium dioxide nanocomposite particles, raise the temperature to 30° C., and react for 48 hours to obtain a dispersion containing platinum-titania nanocomposite particles.

[0053] High-speed centrifugation separates the platinum-titania nan...

Embodiment 3

[0056] Weigh emulsifier SPAN-809.0g and OP-109.0g, dissolve in 100g hexadecane to obtain emulsifier solution.

[0057] Dissolve 0.1 g of silver tetrafluoroborate into a mixed solution composed of 38 g of dimethylformamide and 0.8 g of water to obtain a silver salt solution, add the silver salt solution to the above-mentioned emulsifier solution, and disperse the above-mentioned mixed solution with ultrasonic waves, A stable inverse miniemulsion was obtained.

[0058] At 90°C, 10 g of tetraisopropyl titanate was added to the above inverse miniemulsion, the temperature was raised to 150°C, and the reaction was carried out for 30 minutes to obtain a dispersion containing silver salt-titanium dioxide nanocomposite particles.

[0059] Add 0.6 g of 80% hydrazine hydrate to the above dispersion containing silver salt-titanium dioxide nanocomposite particles, raise the temperature to 50° C., and react for 1 hour to obtain a dispersion containing silver-titania nanocomposite particles....

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com