Graphene-heme and nanogold ternary composite material, preparation method and application

A composite material and heme technology, applied in the field of graphene-heme and nano-gold ternary composite materials and preparation, can solve the problems of complex preparation steps, low efficiency, poor catalytic activity, etc., and achieve high degradation efficiency and cost. Low effect, simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1, the preparation of graphene-heme and nano-gold ternary composite material

[0029] Weigh 3g of natural graphite powder and 3g of sodium nitrate into a round bottom flask, mix well with 70mL of concentrated sulfuric acid in an ice bath, slowly add 9g of potassium permanganate in batches while stirring, and keep the temperature of the mixture below 20°C. After the potassium permanganate and the solution are fully mixed, transfer the above solution to an oil bath at 35±5°C for 30 minutes until a viscous mixture is formed. Then gradually add 140mL of pure water, and raise the temperature to 95±5°C to continue the reaction for 5h. Finally, 500 mL of pure water was added to terminate the reaction. At the same time, 20 mL of hydrogen peroxide solution with a mass fraction of 30% was added to remove unreacted potassium permanganate. At this time, the mixture changed from brown to bright yellow, and the above solution was cooled to room temperature. After suction ...

Embodiment 2

[0030] Embodiment 2, the characterization of graphene-heme and nano-gold ternary composite material

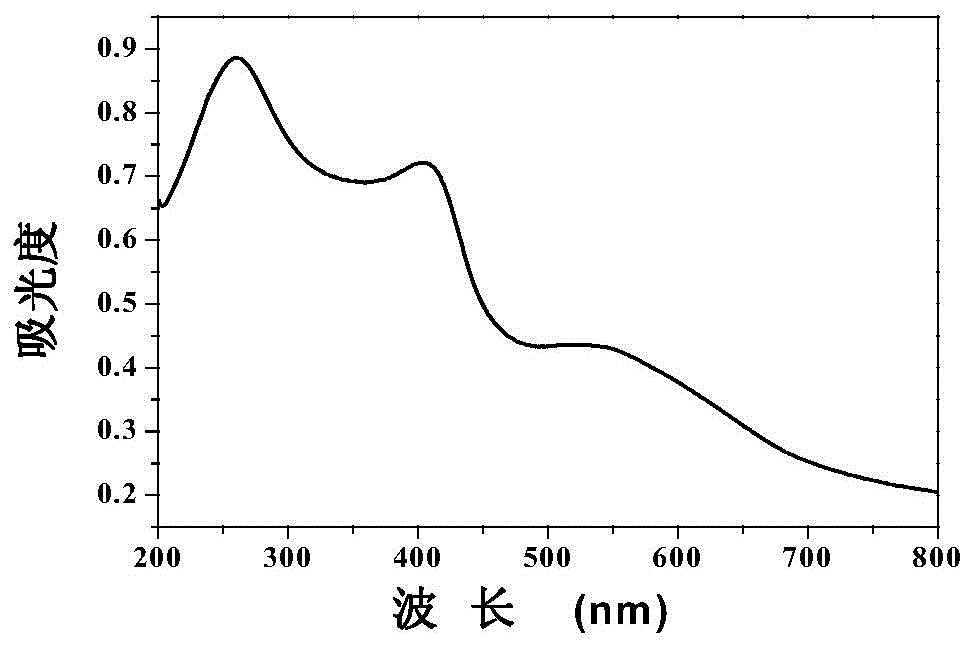

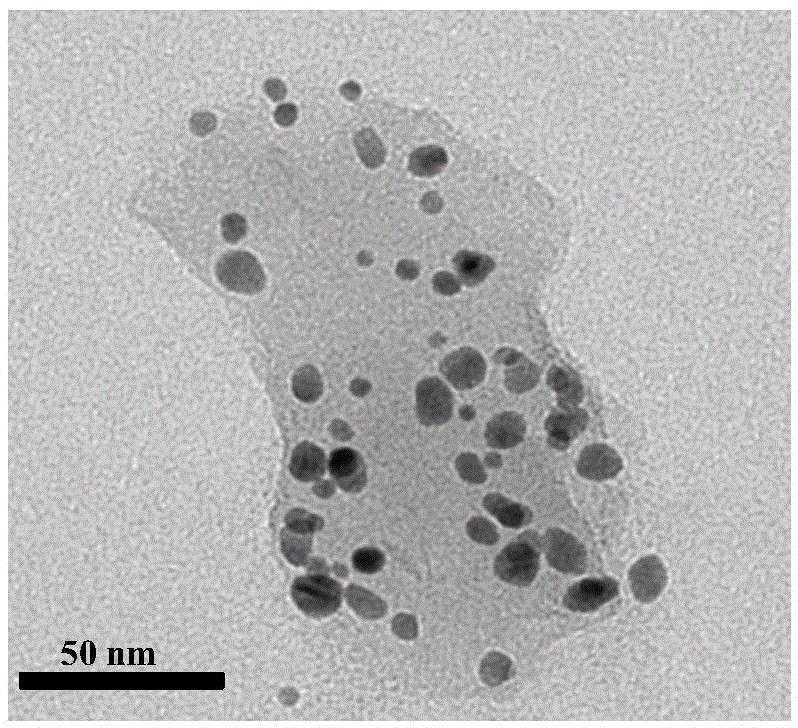

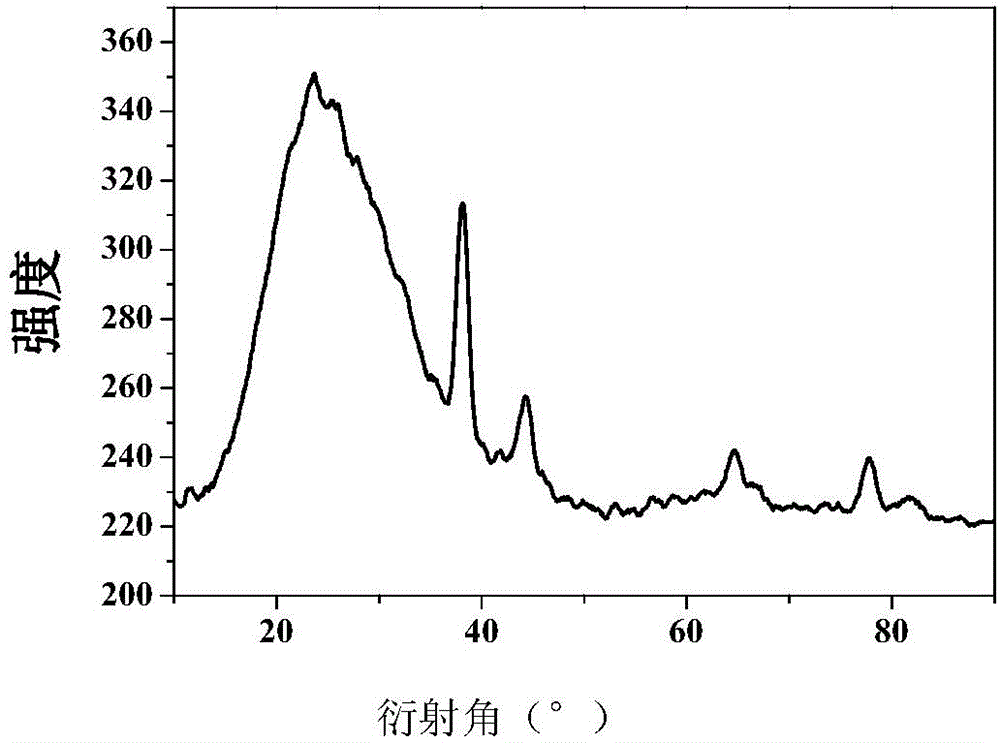

[0031] Get the ternary composite material solution 3mL of the above-mentioned prepared graphene-heme and nano-gold, and analyze it with an ultraviolet spectrophotometer, and the analysis results are shown in figure 1 . Take 10 μL of the ternary composite material and drop it on the copper grid for the analysis of transmission electron microscope (TEM) and energy spectrum (EDS). The results are shown in figure 2 and 4 . Take 100mL composite material solution and drop it on the silicon chip, carry out XRD analysis after drying, its result is shown in image 3 .

Embodiment 3

[0032] Embodiment 3, the high-efficiency enzyme performance description of graphene-heme and nano-gold ternary composite material

[0033] Prepare a TMB solution with a concentration of 100 μmol / L, a hydrogen peroxide solution with a concentration of 100 μmol / L, and a composite material dispersion with a concentration of 120 μg / mL, and then mix 100 μL, 200 μL, and 100 μL respectively, and finally carry out equal time intervals. Ultraviolet Spectrum Scanning. It can be known from the scanning curve that the TMB oxidation product has a characteristic absorption peak at 652nm. Figure 5 , so that we can use this absorption peak to monitor the decomposition rate of hydrogen peroxide, fix TMB, the concentration of hydrogen peroxide remains unchanged, use graphene-heme, nano gold, graphene-heme composite materials, graphene-nano Gold composite material, nano-gold-heme composite material instead of graphene-heme-nano-gold composite material can prove the high efficiency of this tern...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com