Preparation method for coating of nano-silica through miniemulsion polymerization

A nano-silica, mini-emulsion polymerization technology, applied in the direction of dyed organosilicon compound treatment, dyed polymer organic compound treatment, fibrous filler, etc., can solve the decrease of organic/inorganic interface strength, unfavorable application, detrimental silane coupling It can improve the uniformity of treatment, increase the lipophilicity, and achieve the effect of high polymerization efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

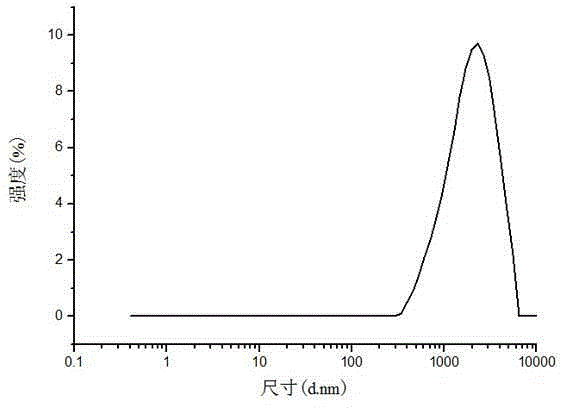

[0032] Example 1: Synthesize P(St-g-KH550) copolymer by ATRP method and introduce microemulsion polymerization to realize nano-silica coating

[0033] Polymerization steps:

[0034] (1) Preparation of P(St-g-KH550)

[0035] Add 20 g of styrene (St) monomer to a 100 mL flask with a stirring device, add 40 mL of ethyl acetate, 1.3 mL of triethylamine, stir under an ice bath, and use a constant pressure dropping funnel to dropwise add 1 mL of 2- The mixed solution of bromoisobutyryl bromide and 10 mL ethyl acetate was dripped in 0.5 h, then the ice bath was removed and the mixture was raised to room temperature and kept stirring for 1 h in the dark. After the completion of the reaction, the product was diluted with tetrahydrofuran (THF), and the reaction mixture was poured into methanol for precipitation, filtered, and vacuum dried to constant weight. The polymer product was dissolved in THF, and the solution was passed through Al 2 O 3 The column adsorbs and removes the copp...

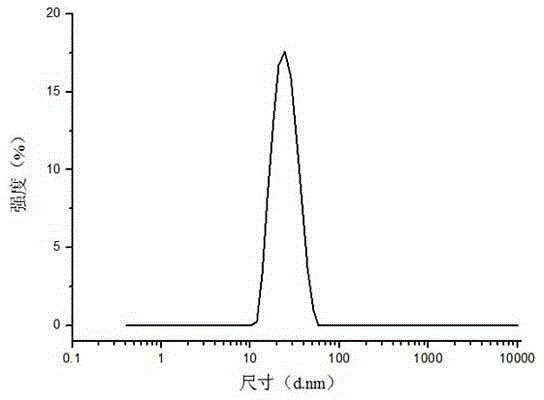

Embodiment 2

[0040] Example 2: Synthesize P(St-g-KH560) copolymer by ATRP method and introduce microemulsion polymerization to realize nano-silica coating

[0041] Polymerization steps:

[0042] (1) Preparation of P(St-g-KH560)

[0043] Add 20 g of styrene monomer to a 100 mL flask with a stirring device, add 40 mL of ethyl acetate, 1.3 mL of triethylamine, stir under an ice bath, and use a constant pressure dropping funnel to add dropwise containing 1 mL of 2-bromoiso The mixed solution of butyryl bromide and 10 mL of ethyl acetate was dripped in 0.5 h, then the ice bath was removed and the mixture was raised to room temperature to continue stirring for 1 h in the dark. After the reaction, the product was diluted with tetrahydrofuran (THF), and the reaction mixture was poured into methanol to precipitate, filtered, and dried in vacuum to a constant weight. The polymer product was dissolved in THF, and the solution was passed through Al 2 O 3 The column adsorbs and removes the c...

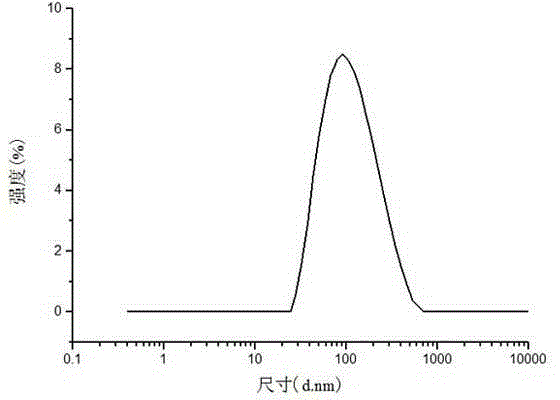

Embodiment 3

[0048] Example 3: Synthesize P(St-g-KH570) copolymer by ATRP method and introduce microemulsion polymerization to realize nano-silica coating

[0049] Polymerization steps:

[0050] (1) Preparation of P(St-g-KH570)

[0051] Add 20 g of styrene monomer to a 100 mL flask with a stirring device, add 40 mL of ethyl acetate, 1.3 mL of triethylamine, stir under an ice bath, and use a constant pressure dropping funnel to add dropwise containing 1 mL of 2-bromoiso The mixed solution of butyryl bromide and 10 mL of ethyl acetate was dripped in 0.5 h, then the ice bath was removed and the mixture was raised to room temperature to continue stirring for 1 h in the dark. After the completion of the reaction, the product was diluted with tetrahydrofuran (THF), and the reaction mixture was poured into methanol for precipitation, filtered, and vacuum dried to constant weight. The polymer product was dissolved in THF, and the solution was passed through Al 2 O 3 The column adsorbs ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com