Bio-control streptomyce for straw degradation and application thereof

A technology for biocontrol of Streptomyces and straw, applied in the field of soil remediation, can solve problems such as affecting crop growth, difficulty in utilization, and poor soil, and achieve the effects of good application potential, strong tolerance, and increasing soil organic matter content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Preparation of Streptomyces JSD-1 Spore Suspension

[0033] Take the slant of Streptomyces grown on Gaoshi No. 1 solid medium for 3 days, and add 9 mL of sterile water. Gently scrape off the spores with a sterile loop to keep the spores in suspension. Pour the crude spore suspension into a 50 mL centrifuge tube and shake as much as possible on a shaker for about 1 min. Filter the suspension with a test tube equipped with absorbent cotton, pour the green leaves into a centrifuge tube, centrifuge at 3000rpm for 5min to precipitate the spores, and pour out an appropriate amount of supernatant to make the concentration of the spore suspension after mixing 2×10 9 cfu / mL.

[0034] The components of the Gaoshi No. 1 medium are: soluble starch 20.0g, KNO 3 1.0g, K 2 HPO 4 0.5g, MgSO 4 ·7H 2 O0.5g, NaCl0.5g, FeSO 4 ·7H 2 O0.01g, 1L of ultrapure water, adjust the pH to 7.2-7.4. When preparing, first use a small amount of cold water to make the starch into a paste, pour ...

Embodiment 2

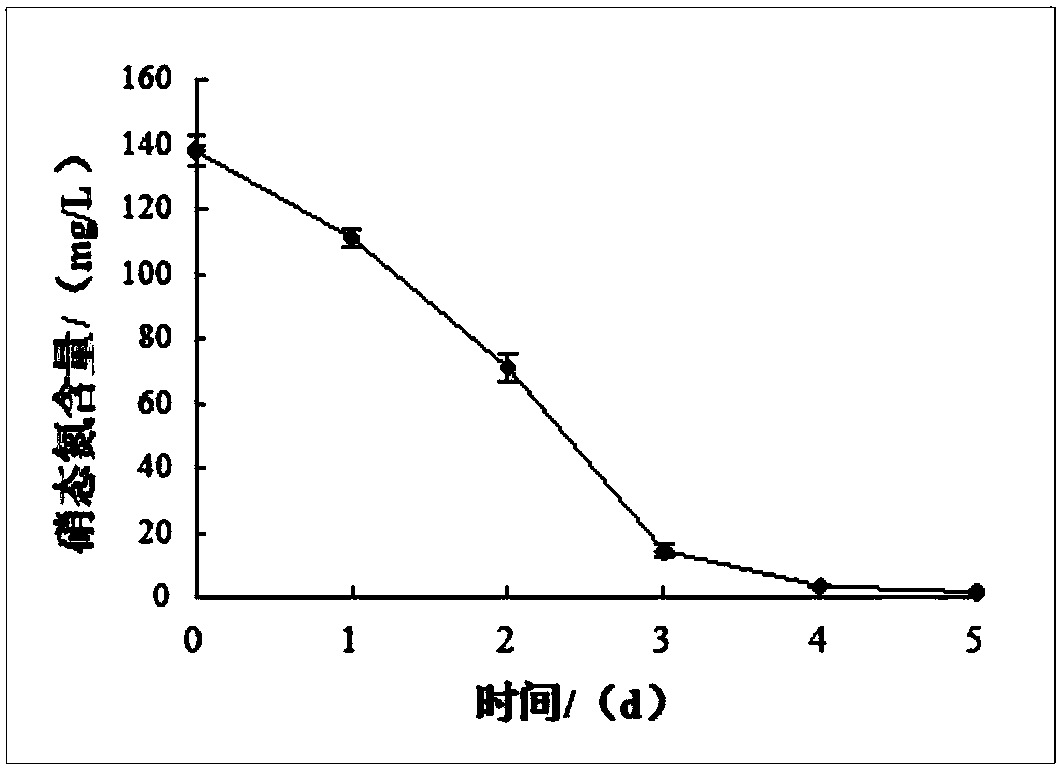

[0036] Streptomyces JSD-1 on fermentation broth (KNO 3 =1g / L) Nitrate nitrogen degradation test

[0037] Take 0.5mL Streptomyces spore suspension and insert 50mL KNO 3The concentration is 1g / L in the fermentation broth, to simulate the salt concentration (content ≥ 1g / L) environment in the secondary salinized soil of mild facilities. Cultured at 30°C and 150rpm for 5 days, samples were taken every 24 hours and diluted 30 times, and the content of nitrate nitrogen in the fermentation broth was measured with an AA3 flow injector. The content of nitrate nitrogen in the fermentation broth was determined as figure 1 As shown, the concentration of nitrate nitrogen in the fermentation broth decreased rapidly on the 1st day; by the 3rd day, the nitrate nitrogen content in the fermentation broth had dropped to 14.3 mg / L, which was nearly 90% lower than the initial concentration; by the 4th day, The content of nitrate nitrogen in the fermentation broth dropped to a very low level, th...

Embodiment 3

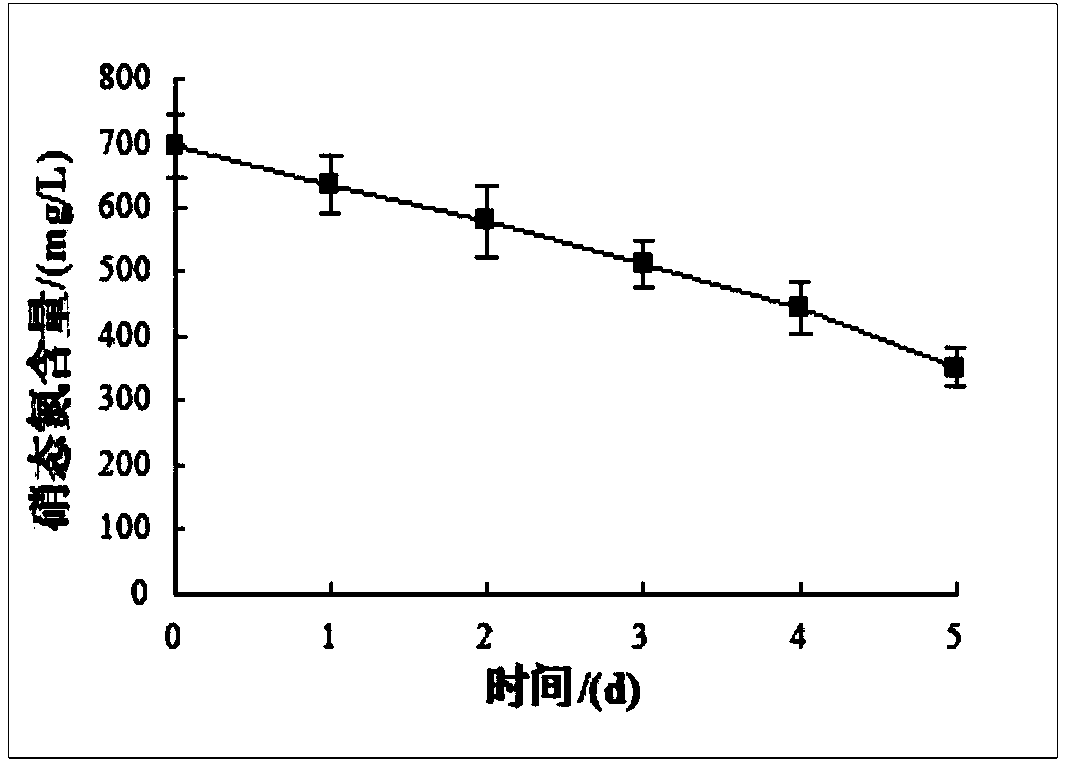

[0040] Streptomyces JSD-1 on fermentation broth (KNO 3 =5g / L) Nitrate nitrogen degradation test

[0041] Take 0.5mL Streptomyces spore suspension into 50mL KNO 3 Concentration is 5g / L in the fermented liquid, to simulate the salinity concentration (content ≥ 5g / L) environment in secondary salinized soil of moderate facility. Cultured at 30°C and 150rpm for 5 days, sampled every 24 hours and diluted 200 times, then used AA3 flow injector to measure the content of nitrate nitrogen in the fermentation broth. The content of nitrate nitrogen in the fermentation broth was determined as figure 2 As shown, the concentration of nitrate nitrogen in the fermentation broth began to decrease on the first day, and there was no obvious process of adapting to the environment; the degradation rate of nitrate nitrogen was relatively stable throughout the 5-day fermentation period. at KNO 3 In the fermentation broth with a content of 5g / L, the degradation rate of nitrate nitrogen by Strepto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com