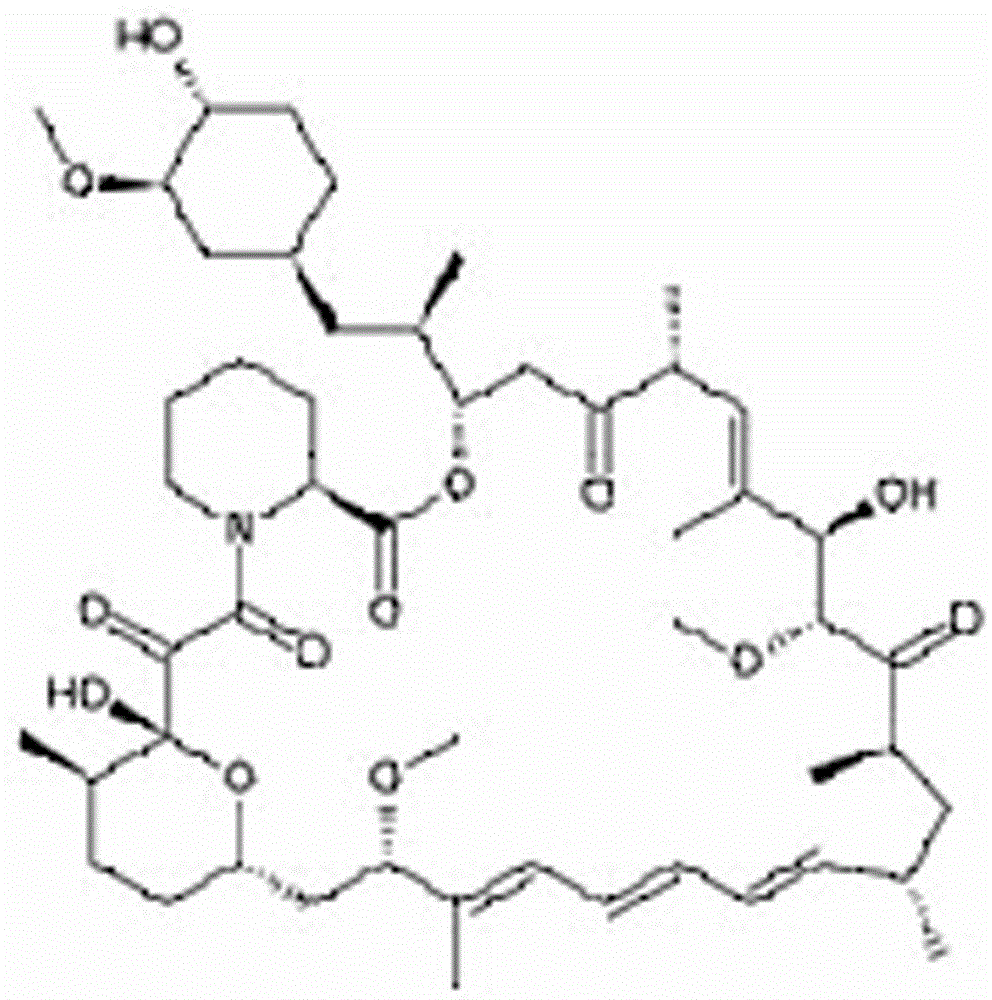

Process for fermenting rapamycin with high yield

A technology of rapamycin and fermentation technology, which is applied in the field of high-yield rapamycin fermentation technology, can solve the problems of low cell density, unreasonable feeding, high viscosity, etc., to reduce metabolic intermediate products, increase content, and increase production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

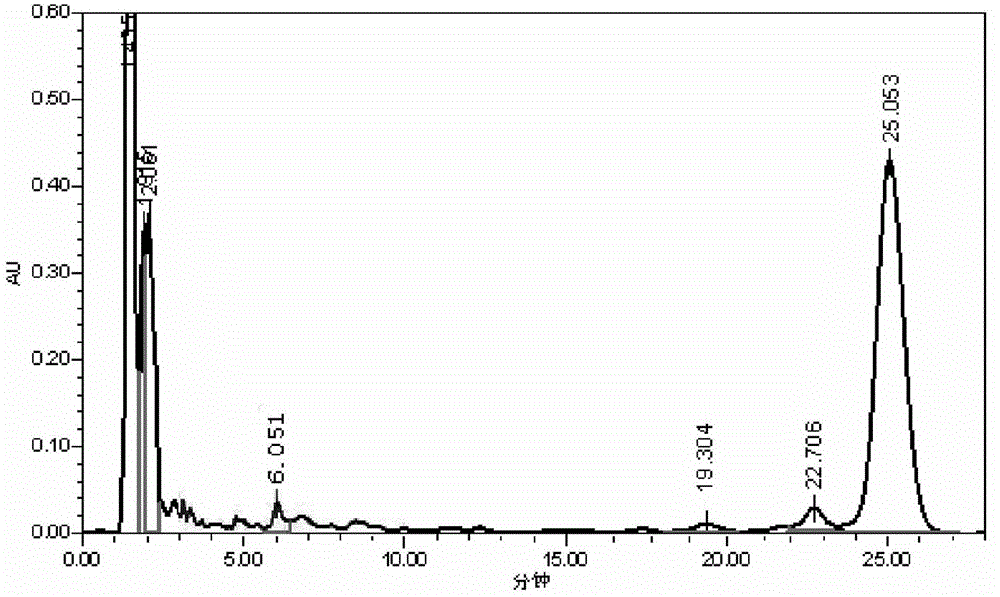

Examples

Embodiment 1

[0036] Evenly spread the rapamycin spore suspension diluted to a certain concentration on a plate filled with 30ml slant medium, the medium is soybean powder 1g / L, soluble starch 10g / L, K 2 HPO 4 0.5g / L, MgSO 4· 7H 2 O 1g / L, agar 20g / L, cultivated in a biochemical incubator at 28°C for 11 days, picked a single colony and cultivated it on the slant of the test tube.

[0037] Use an inoculation spatula to take a ring from the slant of the cultured rapamycin-producing bacteria and inoculate it into a 250ml Erlenmeyer flask containing 30ml of seed medium. The shaker speed is 200r / m, the temperature is 30°C, and cultured for 52h.

[0038] Inoculate the seed culture liquid into a 400L primary seed tank with 200L seed culture liquid according to the inoculation amount of 1% by volume, and the air volume is 2.0m 3 / h, the tank pressure is 0.02MPa, the stirring speed is properly adjusted so that the dissolved oxygen is not lower than 10%, the culture temperature is 30°C, and cultur...

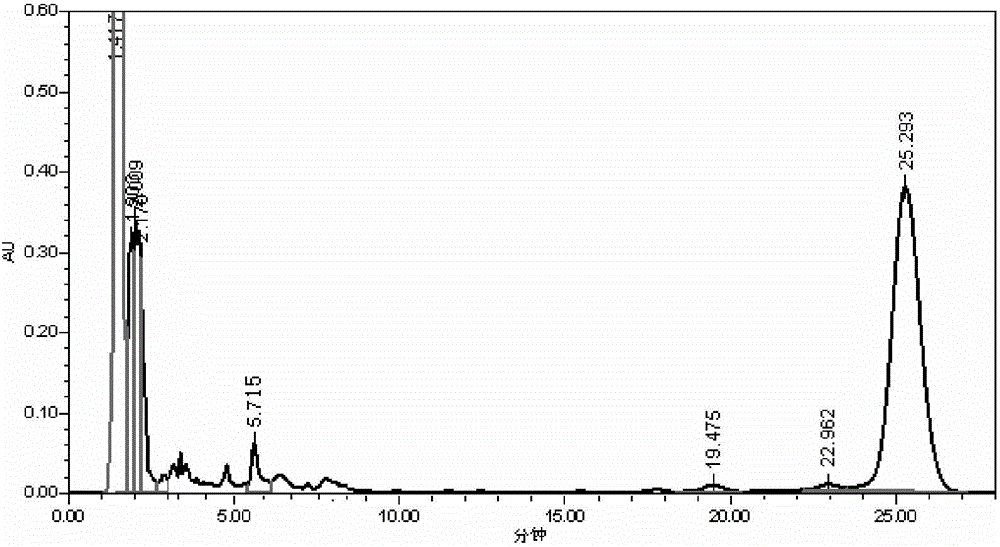

Embodiment 2

[0043] Inoculate the prepared seeds with 3% inoculum by volume and inoculate the seed culture solution into a 400L primary seed tank with 250L seed culture solution, with an air volume of 2.0m 3 / h, the tank pressure is 0.02MPa, the stirring speed is properly adjusted so that the dissolved oxygen is not lower than 10%, the culture temperature is 30°C, and cultured for 48h. Seed medium comprises the following components and content: peptone 10g / L, yeast extract 6g / L, glucose 20g / L, L-lysine 5g / L, NaH 2 PO 4 0.5g / L, adjust the pH to 6.8 before sterilization, and sterilize at 121°C for 45min.

[0044] Inoculate the seed culture solution into a 2200L secondary seed tank with 1500L seed medium according to the volume ratio of 10% inoculum, and the air volume is 2.2m 3 / h, the tank pressure is 0.02MPa, the stirring speed is properly adjusted so that the dissolved oxygen is not lower than 10%, the culture temperature is 30°C, and cultured for 48h.

[0045] Put the seed culture so...

Embodiment 3

[0047] Inoculate the prepared seeds with 3% inoculum by volume and inoculate the seed culture solution into a 400L primary seed tank with 250L seed culture solution, with an air volume of 2.0m 3 / h, the tank pressure is 0.02MPa, the stirring speed is properly adjusted so that the dissolved oxygen is not lower than 10%, the culture temperature is 30°C, and cultured for 48h. Seed medium includes the following components and contents: peptone 10g / L, yeast extract 6g / L, glucose 20g / L, L-lysine 5g / L, NaH 2 PO 4 0.5g / L, adjust the pH to 6.8 before sterilization, and sterilize at 121°C for 45min.

[0048] Inoculate the seed culture solution into a 2200L secondary seed tank with 1500L seed medium according to the volume ratio of 10% inoculum, and the air volume is 2.2m 3 / h, the tank pressure is 0.02MPa, the stirring speed is properly adjusted so that the dissolved oxygen is not lower than 10%, the culture temperature is 30°C, and cultured for 48h.

[0049] Put the seed culture...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com