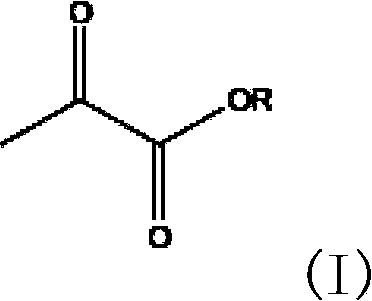

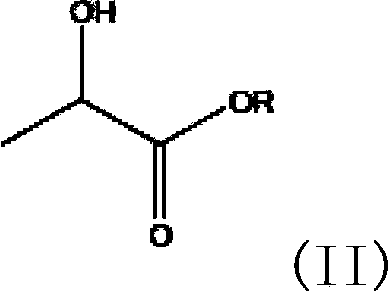

Method for preparing pyruvate ester

A technology of pyruvate and lactate, which is applied in the field of solid-liquid phase reaction system to prepare pyruvate, can solve the problems of environmental pollution, difficult product purification, and many reaction by-products, and achieves simple and easy-to-operate, high-efficiency Effect of pyruvate selectivity and high lactate conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0020] Preparation Example 1 The preparation of titanium-silicon molecular sieve

[0021] The titanium-silicon molecular sieves used in the following reactions are all prepared in this way.

[0022] First, 1.98 g of tetra-n-butyl titanate was added to a 500 ml round bottom flask equipped with a vacuum system and an isobaric feeding system, and nitrogen blanketing was carried out. The nitrogen-covered round-bottom flask was cooled to 5° C., and after the temperature was balanced, 30 g of tetraethylsilicate was added dropwise into the nitrogen-covered round-bottom flask using the isobaric feeding system. After the dropwise addition was complete, stir at 5° C. for 1 hour. Afterwards, get the isopropanol solution (20% by weight) of the tetra-n-propylammonium hydroxide of 56 grams, use this isobaric feeding system to add dropwise in this nitrogen-covered round-bottomed flask equally, treat to drop after finishing and finish in 5 Stir for 1 hour at °C. Next, 44.8 g of water was a...

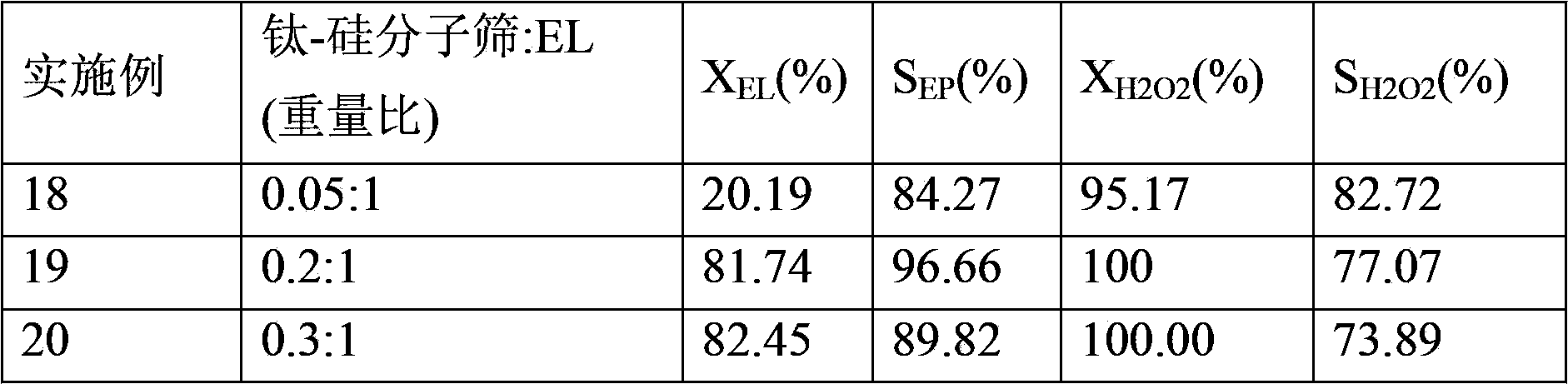

Embodiment 1 to 2

[0024] The purpose of Examples 1 to 2 is to screen the reaction solvent. Add 1 gram of the titanium-silicon molecular sieve of Preparation Example 1 in a 250 milliliter three-necked round-bottomed flask equipped with a condenser tube and a stirring system according to the contents recorded in Table 1, and 20 grams of the titanium-silicon molecular sieve as listed in Table 1. 2 solvent, and 5 g of ethyl lactate as a reactant. After the reaction temperature was raised to 70° C., 4.11 grams of hydrogen peroxide aqueous solution (35% by weight) was gradually added over the reaction time to carry out the preparation reaction of ethyl pyruvate. After completing the hydrogen peroxide feed for 1 hour, continue to react at this temperature for 5 hours. After the reaction is terminated, the titanium-silicon molecular sieve catalyst is separated from the reaction solution by filtration, and each reaction solution after the separation is separated by gas chromatography. (Varian CP-3800, ...

Embodiment 3 to 7

[0039] The purpose of Examples 3 to 7 is to adjust the reaction temperature. Add 1 gram of the titanium-silicon molecular sieve of Preparation Example 1, 20 grams of tert-butanol as a solvent, and 5 grams of lactic acid in a 250 milliliter three-necked round-bottomed flask equipped with a condenser tube and a stirring system according to the contents shown in Table 3 respectively. Ethyl esters were used as reactants. After raising the reaction temperature to the temperature shown in Table 3, 4.11 g of hydrogen peroxide aqueous solution (35% by weight) was gradually added over the reaction time to carry out the preparation reaction of ethyl pyruvate. After completing the hydrogen peroxide feed for 1 hour, continue to react at this temperature for 5 hours. After the reaction is terminated, the titanium-silicon molecular sieve catalyst is separated from the reaction solution by filtration, and the separated reaction solutions are subjected to gas chromatography. and titrator ana...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com