Saccharomyces cerevisiae engineering bacterium for highly yielding medium-chain fatty acid ethyl ester as well as construction method thereof

A technology of fatty acid ethyl ester and yeast engineering, applied in the field of bioengineering, can solve the problem of low ester production capacity of Saccharomyces cerevisiae

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: Construction of high-yield ethyl caproate Saccharomyces cerevisiae genetically engineered bacteria

[0034] (1) Construction of genetic engineering strains

[0035] 1) Construction of pUC-APEKB plasmid

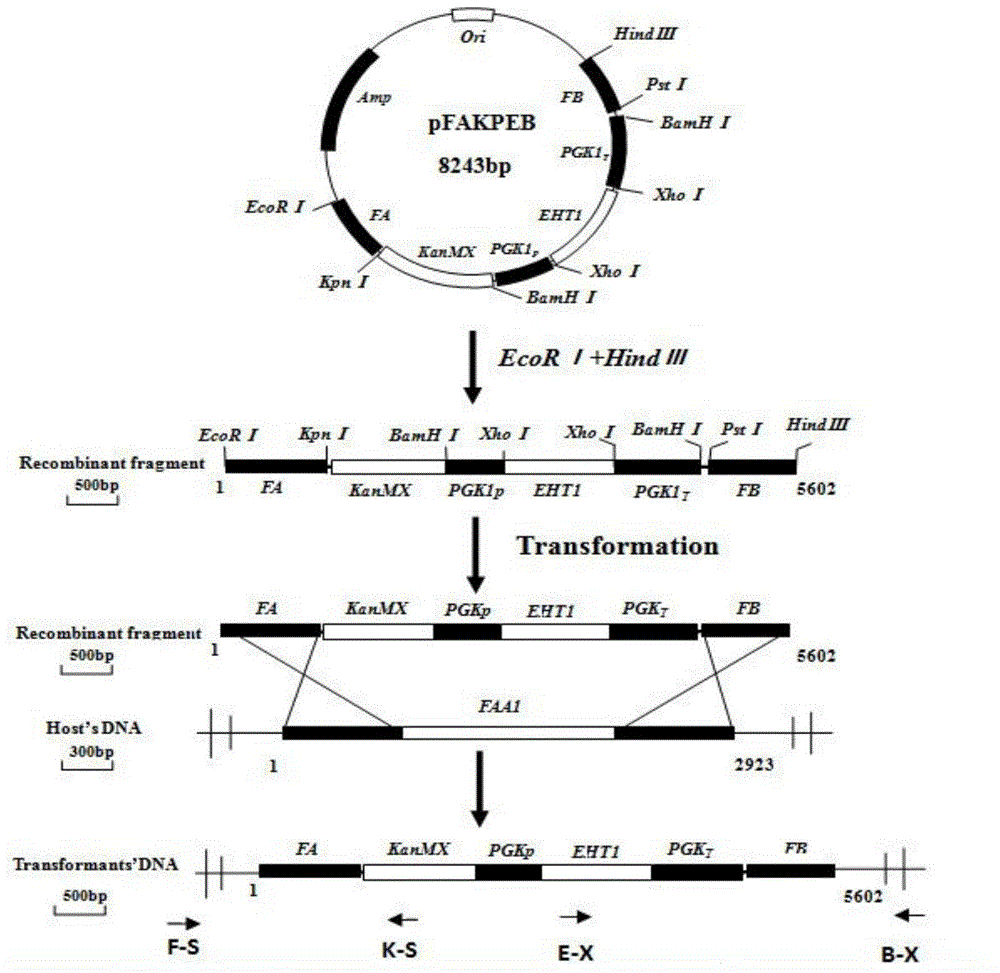

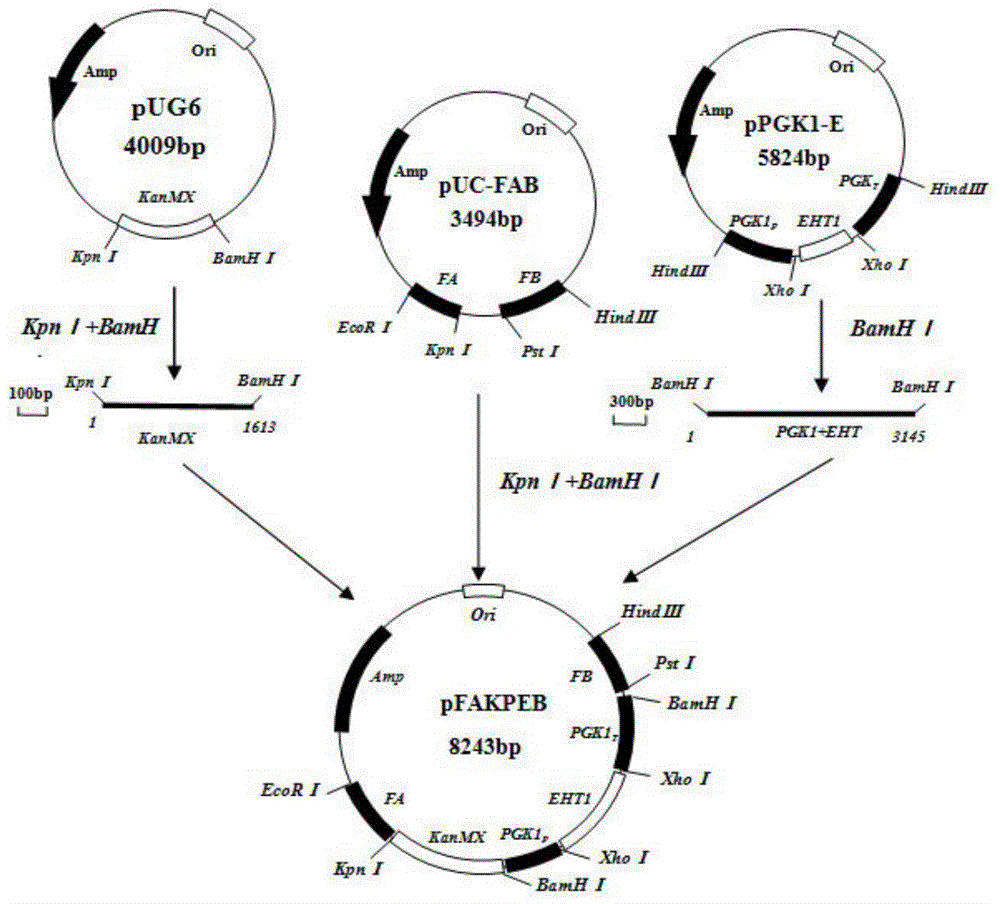

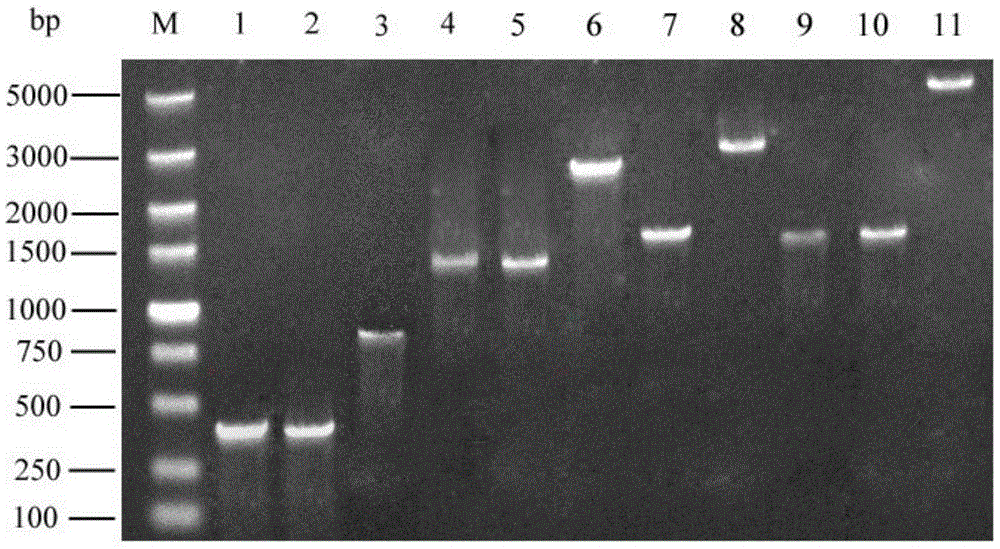

[0036] Using pUC-19 as the base plasmid to construct the homologous recombination plasmid pUC-APEKB, the construction process is as follows: figure 1 As shown, the 411bp upstream homology arm FA and the 409bp downstream homology arm FB were amplified by PCR using the haploid a8 or α5 of AY15 as a template, which were passed through EcoRI / KpnI and PstI / Hind III Double digestion and ligation into pUC-19 to obtain plasmid pUC-FAB. The 1356bp alcohol hexanoyltransferase gene EHT1 was amplified by PCR using the haploid a8 or α5 of AY15 as a template, and the promoter PGK1p and terminator PGK1 were inserted into the pPGK1 plasmid by XhoI single enzyme digestion T Between, the plasmid pPGK1-E was obtained; using the pPGK1-E plasmid as a template, PCR amplifi...

Embodiment 2

[0057] Embodiment 2: Fermentation experiment of simulated corn raw material liquid liquor

[0058] 1) Fermentation process route:

[0059] Corn flour→soaking→liquefaction→saccharification→cooling→inoculation→fermentation→steaming wine→measurement index

[0060] 2) Process conditions: soaking conditions: 60-70°C, immersion for 20 minutes; liquefaction conditions: 85-90°C, add high-temperature-resistant α-amylase, liquefy for 90 minutes; saccharification conditions: 55-60°C, add glucoamylase, saccharify for 20 minutes and ferment Conditions: 30°C, 15 days. When steaming wine, take 100mL mash, add 100mL water, and steam 100mL wine sample.

[0061] 3) Ingredients: corn flour: 60g; add water 180mL; high temperature resistant α-amylase: 30μL; glucoamylase: 90μL; acid protease: 1.2mL; nutrient salt: 1mL;

[0062] According to the above simulation process, the Saccharomyces cerevisiae engineering bacteria a8-1, α5-1, EY15 and the starting strains a8, α5, AY15 were respectively subj...

Embodiment 3

[0070] Embodiment 3: Fermentation experiment of solid-state Daqu liquor

[0071] 1) Fermentation process route:

[0072] Sorghum→soaking→cooking→drying→mixing koji→culture and saccharification for 24 hours→inoculation→fermentation→distillation

[0073] 2) Process conditions: soaking conditions: 95-98°C, fully absorb water without hard core; steaming conditions: steam at normal pressure for about 30 minutes, uniform particles, no white inside. Fermentation conditions: 30°C, 15 days. Wine steaming conditions: 100g distiller's grains, add 100mL water, distill 100mL wine sample.

[0074] 3) Ingredients: sorghum 50g; Daqu 5g; inoculation amount: 5%;

[0075] According to the above simulation process, the Saccharomyces cerevisiae engineering bacteria a8-1, α5-1, EY15 and the starting strains a8, α5, AY15 were respectively subjected to solid-state Daqu liquor fermentation experiments; during the fermentation period, oscillate and weigh every 12 hours, and record the weight loss; a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com