High-temperature solid-phase synthesis method of one-dimensional nano-sodion cell anode material NaxMnO2

A technology for ion batteries and cathode materials, applied in battery electrodes, non-aqueous electrolyte storage batteries, circuits, etc., can solve the problems of uneven product morphology, long reaction time, and large sodium consumption, and achieve good electrochemical performance and synthesis The effect of shortening time and reducing sodium consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1, one-dimensional nanometer sodium ion battery cathode material Na x MnO 2 Synthesis

[0041] Take 11.6ml50%(w / w)Mn(NO 3 ) 2 solution and 2.295g NaNO 3 Dissolve in 18ml of deionized water, stir to fully dissolve to obtain liquid I; dissolve 14.795g of citric acid in 24.6ml of deionized water to obtain liquid II; slowly drop liquid I into liquid II, stir for 10min, heat and evaporate at 90°C Remove the solvent, transfer the residue to an oven at 120°C for heat treatment for 24 hours, cool to room temperature, and grind it into a powder. The obtained powder continues to be heat treated at 450°C for 6 hours, cooled to room temperature, and ground into a powder, and then heat the obtained powder at 900°C 15h, cooled to room temperature to obtain the final product.

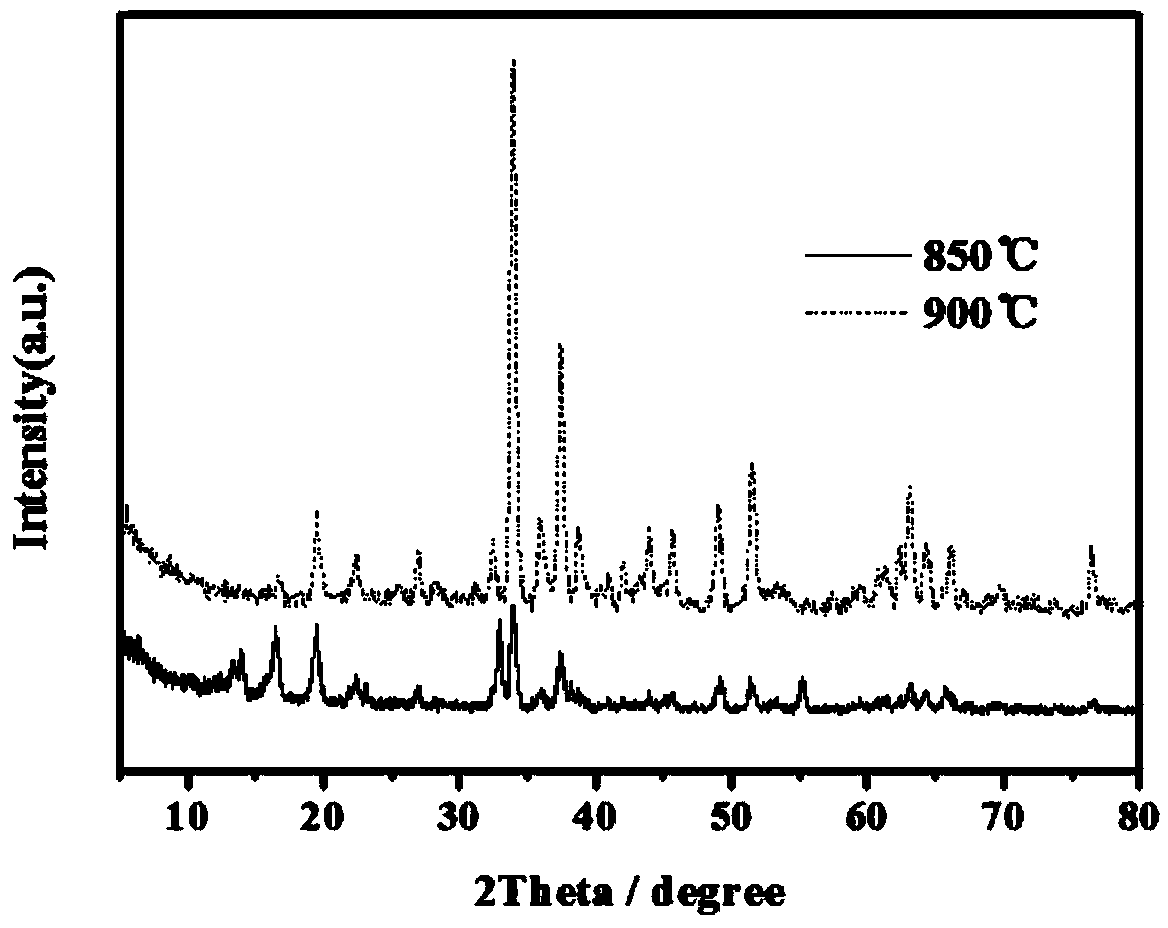

[0042] The shape of the final product is as figure 1 As shown, the crystallinity is very high, and it is in the form of thin flakes, and the existence of nanowires can be seen; the composition ...

Embodiment 2

[0043] Embodiment 2, one-dimensional nanometer sodium ion battery cathode material Na x MnO 2 Synthesis

[0044] Take 11.6ml50%(w / w)Mn(NO3 ) 2 solution and 1.912g NaNO 3 Dissolve in 15ml of deionized water, stir to fully dissolve to obtain liquid I; dissolve 13.930g of citric acid in 23ml of deionized water to obtain liquid II; slowly drop liquid I into liquid II, stir for 10min, heat and evaporate at 80°C to remove Solvent, the residue was transferred to a 120°C oven for heat treatment for 12 hours, cooled to room temperature, and ground into a powder. The obtained powder continued to be heat treated at 400°C for 3 hours, cooled to room temperature, and ground into a powder, and then the obtained powder was treated at 850°C for 15 hours. Cool to room temperature to obtain the final product.

[0045] The shape of the final product is as figure 2 As shown, it is uniform ultra-thin sheet; the component analysis results are as follows image 3 (solid line), Na x MnO 2 Th...

Embodiment 3

[0046] Embodiment 3, the preparation of battery and one-dimensional nano-sodium ion battery cathode material Na x MnO 2 Electrochemical performance test of

[0047] Get the product obtained in Example 2, conduction carbon black, and PVDF binder in a mass ratio of 80:10:10, add a certain amount of 1-methyl-2-pyrrolidone (NMP), grind it into a paste with an agate mortar, Then coated on aluminum foil with a diameter of 12mm, each piece of active material load is about 1mg, dried in a vacuum oven at 120°C for 12h, cooled to below 40°C, taken out and weighed, transferred to an argon glove box for assembly . The button battery model is CR2025, the negative electrode is sodium sheet, the diaphragm is Celgard2325, and the electrolyte is 1M NaClO 4 solution (the solvent is EC and DMC in a volume ratio of 1:1). The assembled battery is placed for more than 6 hours to be tested. Electrochemical tests were performed on a Land test system. The voltage range is 2-4V, and the current s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com