Method for preparing breast milk fat substitute through lipase-catalyzed acidolysis of algae oil

A technology of breast milk fat and lipase, which is applied in the direction of fermentation to achieve the effect of improving resource utilization and extending the industrial chain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] This example illustrates the extraction of triglycerides from microalgae.

[0025] Mix the dried algae powder with the solvent ether, heat and extract for 0.5h under the assisted condition of ultrasound (200W), remove the residue by suction filtration, distill under reduced pressure at 45°C to obtain crude fat, dehydrate after centrifugation, and finally refine to obtain algae Triglycerides of oil.

[0026] After methyl esterification, it was detected by gas chromatography. Algal oil contains lauric acid (Lauric acid, C 14:0 ) and palmitic acid (C 16:0) saturated fatty acid (Saturated fatty acid, SFA), respectively 5.5% and 19.1%; in addition, unsaturated fatty acid (Unsaturated fatty acids, USFA) oleic acid (Oleic acid, C 18:1 ), linoleic acid (Linoleic acid, C 18:2 ), DPA (Docosapentenoic acid, C 22:5 ) and DHA (Docosahexaenoic Acid, C 22:6 ) content were 19.9%, 1.6%, 16.1% and 36.4%.

[0027] The solvent can also be ethanol, n-butanol, acetone, n-hexane, cyclo...

Embodiment 2

[0030] This example illustrates the process of lipase-catalyzed transesterification of algal oil (rich in triglycerides) and oleic acid.

[0031] Refined algae oil (98% triglyceride content) 9.5g and 2.82g oleic acid (1:1 molar ratio), add 0.37g (3% substrate weight) Sn-1, 3-position specific lipase Lipozyme RM IM , the reaction temperature is 90°C, and the reaction time is 10h.

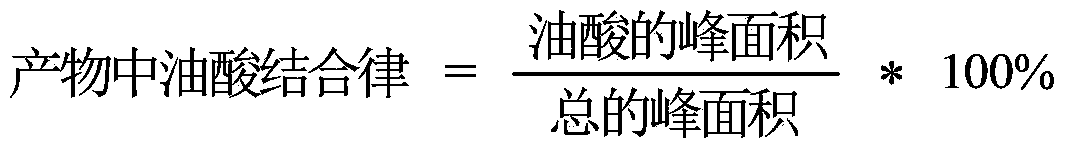

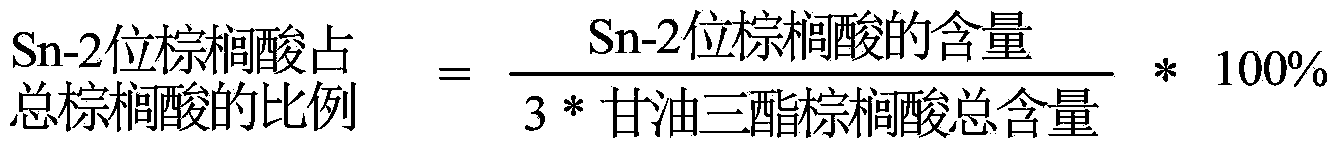

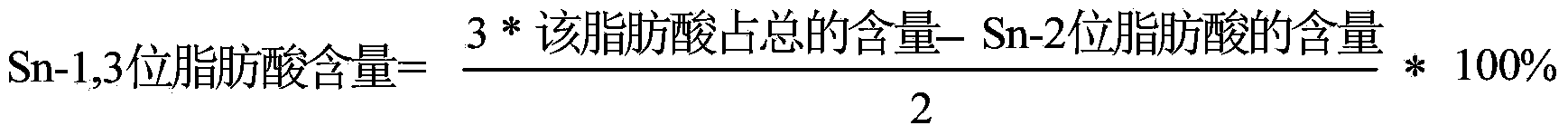

[0032] After the reaction, take out 300 μL, add 50 mg porcine pancreatic lipase to hydrolyze for 5 min, extract with ether, take the organic layer for thin-layer chromatography, and scrape the bands of Sn-2 monoglyceride and triglyceride respectively. Add 2mL of n-hexane and 2mL of 0.5M KOH-methanol solution and react in a water-bath shaker at 65°C for 30min to carry out methyl esterification, and then perform gas chromatography detection, Sn-1, 2, 3 fatty acid content (Sn-2 FA content The FA at the sn-2 position accounts for the total content of the FA in the triglyceride) see Table 1.

[0033] Ta...

Embodiment 3

[0036] This example illustrates the process of lipase-catalyzed transesterification of algal oil (rich in triglycerides) and oleic acid.

[0037] Refined algae oil (98% triglyceride content) 9.5g and 14.1g oleic acid (1:5 molar), added 2.1g (9% substrate weight) Sn-1,3 position specific lipase Lipozyme RM IM, the reaction temperature is 65°C, and the reaction time is 3h.

[0038] After the reaction, take out 300 μL, add 50 mg porcine pancreatic lipase to hydrolyze for 5 min, extract with ether, take the organic layer for thin-layer chromatography, and scrape the bands of Sn-2 monoglyceride and triglyceride respectively. Add 2mL of n-hexane and 2mL of 0.5M KOH-methanol solution and react in a water-bath shaker at 65°C for 30min to carry out methylation, and then detect by gas chromatography.

[0039] Table 2. Sn-1, 2, 3 fatty acid content

[0040]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com