Preparation method of chitosan microcapsule with uniform size and controllable size

A chitosan microcapsule and uniform technology, applied in the field of microfluidics, can solve the problems of troublesome post-processing and complicated preparation process, and achieve the effect of simple device, good monodispersity and regular shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

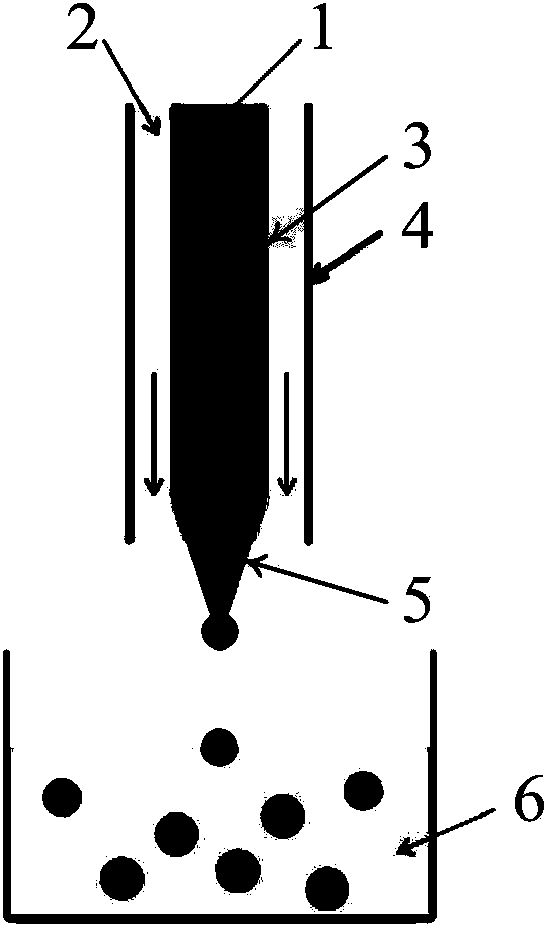

[0035] (1) Self-made microfluidic device

[0036]First, insert a circular capillary 3 with a length of 4 cm (inner diameter 600 μm, outer diameter 1000 μm, one end drawn into a tapered end 5 with an outlet diameter of 200-300 μm) into a square capillary 4 (inner diameter 1000 μm) of about 3 cm, circular The tapered end 5 of the capillary 3 extends about 1mm from one end of the square capillary 4, the undrawn tapered end of the circular capillary 3 extends out of the square capillary 4 and is connected to a PTFE tube (not shown), and the other end of the square capillary 4 is connected to Put the PVC pipe (not shown in the figure); finally, all the connections are glued and sealed by epoxy resin, and after curing for 24 hours, the microfluidic device (such as figure 1 )can use.

[0037] (2) Preparation of chitosan microcapsules

[0038] Add 2g of chitosan to 10mL of 0.2mol / L acetic acid solution, stir for 2 hours at room temperature with a magnet to fully dissolve the chitosa...

Embodiment 2

[0040] Use the self-made microfluidic device in step (1) of Example 1. The chitosan solution in step (2) of Example 1 is controlled by a micro-injection pump, injected into the vertically fixed microfluidic device at 3mL / h, and the gas is also controlled by a rotameter to pass into the microfluidic device at 45L / h. Fluidic device, under the action of gas shear, the internal phase solution forms micro-droplets at the outlet of the microfluidic device, and drops into the 4wt% sodium dodecyl sulfate receiver solution placed directly below the microfluidic device ; Through the neutralization of positive and negative charges, microcapsules are gradually formed, and then after about half an hour of aging, the microcapsules are taken out, washed and stored in water, and finally monodisperse chitosan microcapsules are obtained. The average particle size is 541 μm, and the CV value is 5.83%.

Embodiment 3

[0042] The self-made microfluidic device in step (1) of Example 1 was used. The chitosan solution in step (2) of Example 1 is controlled by a micro-injection pump, and injected into the vertically fixed microfluidic device at 3mL / h; at the same time, the gas is also controlled by a rotameter and passed into the microfluidic device at 60L / h. Fluidic device, under the action of gas shear, the internal phase solution forms micro-droplets at the outlet of the microfluidic device, and drops into the 4wt% sodium dodecyl sulfate receiver solution placed directly below the microfluidic device ; Through the neutralization of positive and negative charges, microcapsules are gradually formed, and then after about half an hour of aging, the microcapsules are taken out, washed and stored in water, and finally monodisperse chitosan microcapsules are obtained. The average particle size is 311 μm, and the CV value is 5.03%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Outlet diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com