Preparation method of tissue-regeneration-promoting controlled-release multiple-growth-factor self-assembled coating

A growth factor, tissue regeneration technology, applied in the field of bio-regenerative medicine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

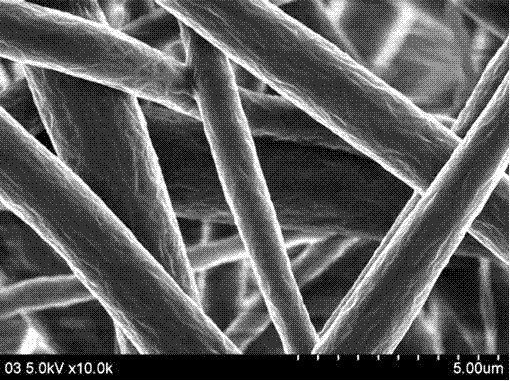

[0049] In step 1, PCL is used as a raw material and dissolved in chloroform to prepare a solution with a mass ratio of 8%. This solution was added to the electrospinning syringe controlled by the syringe pump, the voltage of the high voltage generator was set to 15KV, the collection distance was 16cm, the flow rate of the syringe was 0.5ml / min, and the electrospun film was collected on a square aluminum foil. After natural drying, it was washed several times with ethanol and deionized water, and then dried with nitrogen gas for use.

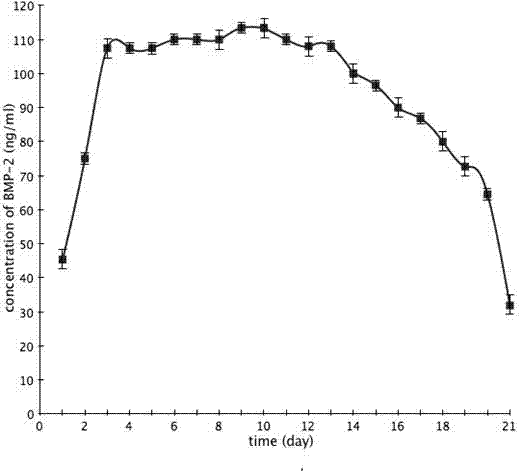

[0050] Step 2: Prepare PAH and PSS polyelectrolyte solutions with a concentration of 1 mg / ml, COL and ALG with a concentration of 0.3 mg / ml, and the NaCl content in the solution is 0.15M. The positively charged BMP-2 solution was dispersed in the above PAH solution, the concentration of BMP-2 wa...

Embodiment 2

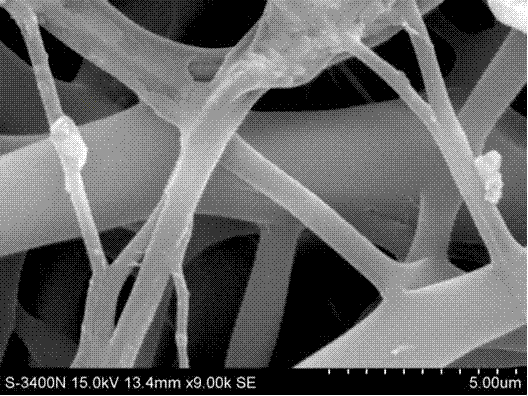

[0068] In step 1, PLGA and collagen (collagen) were used as raw materials (mass ratio: 6:1), and dissolved in hexafluoropropanol to prepare a solution with a mass percentage of 7%. This solution was added to the electrospinning syringe controlled by the syringe pump, the voltage of the high voltage generator was set to 13KV, the collection distance was 14cm, the flow rate of the syringe was 0.02ml / min, and the electrospinning film was collected on the aluminum foil. After collection, it was dried in a vacuum oven (at a temperature of 35°C), and then the dried film was immersed in a 5% EDC solution, cross-linked at room temperature for 1 hour, and washed with ethanol and deionized water several times. Nitrogen dried for use.

[0069] Step 2, preparing a PAH and PAA polyelectrolyte solution with a concentration of 1 mg / ml, and the NaCl content in the solution is 0.15M. The DNCPs were dispersed in a 4mM HCl solution containing 0.1% human serum albumin at a concentration of 30ug / ...

Embodiment 3

[0073] Step 1, use gelatin (Gelatin) and modified chitosan (chitosan) as raw materials (mass ratio is 2:3), dissolve in N-N-dimethylacetamide (DMA), and add 1.0% (wt ) 2-Dimethylamino-2-benzyl-1-[4-(4-morpholinyl)phenyl]-1-butanone as photocuring initiator, at 365nm, 10 w / cm 2 Irradiate under ultraviolet light for 20 minutes to obtain a gel material. The obtained gel is washed under the action of deionized water to remove DMA therein to obtain a porous three-dimensional matrix scaffold. After collection, put it into a vacuum oven (at a temperature of 35°C) for drying, and then immerse the dried scaffold material in a solution of polyethyleneimine (PEI) with a concentration of 2 mg / ml, soak for 10 minutes, and wash with deionized water , dried with nitrogen gas for later use.

[0074] Step 2, prepare PAH and PAA polyelectrolyte solutions with a concentration of 2mg / ml, and the NaCl content in the solution is 0.2M. Disperse bFGF in a 4.5mM HCl solution containing 0.1% human s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com