Carboxylic acid hydrogenation catalyst, preparation method and application thereof

A hydrogenation catalyst and catalyst technology, applied in the petrochemical field, can solve the problems of harsh operating conditions, low selectivity and high reaction pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

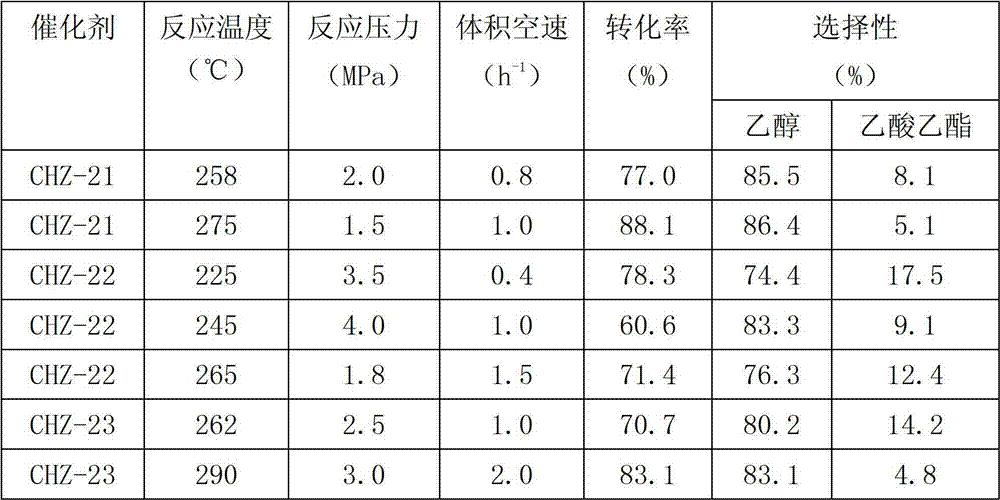

Embodiment 1

[0048] Get 1 liter of cobalt nitrate aqueous solution of 1mol / L, add ammonium molybdate 9.5 grams and lanthanum nitrate 7.5g wherein,

[0049] Add 20wt% sodium carbonate solution for precipitation until the pH value is about 9.0, and stir for 2 hours under heating conditions to obtain the precursor I.

[0050] Add 10g of concentrated nitric acid and 6g of calcium nitrate tetrahydrate into 300ml of water, and slowly add to 500g of diluted water glass aqueous solution (with a silicon dioxide content of about 10wt%) to form a white precipitate, and use a high-power stirrer to stir the precipitate to form Slurry, these slurry substances were added to the precursor I, and the aging was continued for 1 hour under stirring conditions. After washing and filtering, and drying overnight to obtain a dry filter cake, 15 ml of silver nitrate solution containing 0.1 wt % was sprayed into the filter cake and then granulated. The particles were calcined and decomposed, and then pelletized to...

Embodiment 2

[0052] Get 1 liter of cobalt nitrate aqueous solution of 1.5mol / L, add 6.0 grams of cerium nitrate and 4 grams of chromium nitrate therein, fully dissolve, under the situation of stirring, add 60 grams of titanium dioxide powders produced by Degussa Company (the model is P25 , the particle size is greater than 150 mesh), and the resulting solid-containing liquid is called solution I. 250ml of ammonium metatungstate solution (tungsten content is about 1.5wt%) dissolved in ammonia water is solution II; 20wt% sodium carbonate solution is solution III. Pour solution II into solution I for precipitation, and finally use solution III to adjust the pH value to about 6.7. Wash and filter subsequently to obtain a wet filter cake; spray 25ml of boric acid solution containing 0.1wt% in this filter cake and leave it to dry after 1 hour. The dry filter cake is calcined and decomposed and shaped to obtain the catalyst CHZ-22.

Embodiment 3

[0054] Dissolve 240g and 15g of dried cobalt nitrate and chromium nitrate respectively in 800ml of n-propanol under the condition of rising temperature, control the temperature at 50-60°C, slowly add 300g of tetraethyl orthosilicate, and prepare cobalt-containing and chromium orthosilicate. Take 100 g of the above cobalt- and chromium-containing ethyl orthosilicate and dissolve it in ethanol, add 600 ml of water and 5.0 g of concentrated nitric acid, and place it at 75° C. for 6 hours to obtain a gel. Add 20ml of silver nitrate aqueous solution (60mgAg / ml) to the above gel, stir and make a slurry, and spray dry the slurry to obtain fine microspheres. After the above-mentioned microspheres were sieved to remove particles above 300 μm, they were calcined at 400° C., and the above-mentioned powder was shaped into tablets to obtain the catalyst CHZ-23.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com