Polyphosphazene-modified cellular polyurethane elastomer and preparation method thereof

A technology of microporous elastomer and polyurethane, applied in the field of microporous elastomer and its preparation, can solve problems such as difference in mechanical properties, and achieve the effects of improving material properties, easy preparation, and overcoming poor moisture and heat aging resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

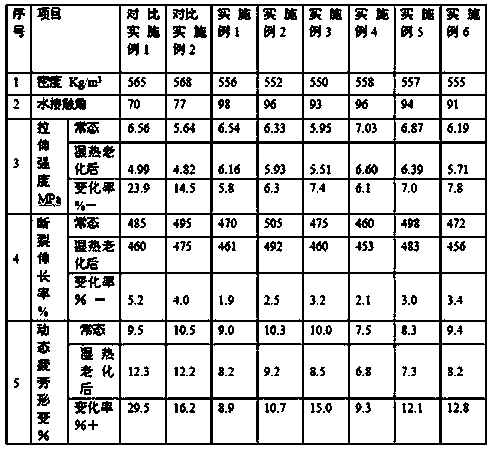

Examples

preparation example Construction

[0024] Preparation of polydichlorophosphazene (PDCP): Add 0.2 g calcium sulfate dihydrate, 0.2 g sulfamic acid, 15.0 g ammonium chloride, 66.0 g phosphorus pentachloride and 50 mL l,2, 4-Trichlorobenzene. Start stirring, pass cooling water, heat up to 195°C, and react for 3 hours, the system slowly turns light brown. Pour all the contents in the flask into petroleum ether, pour off the upper layer solution, add THF to dissolve the lower layer precipitate, let it stand for a few minutes, pour the upper layer liquid into the Erlenmeyer flask, add petroleum ether to precipitate, and then repeatedly purify with THF and petroleum ether 2 times, colorless PDCP was obtained.

[0025] Preparation method of linear phenoxyphosphazene oligomer with hydroxyl

[0026] Dissolve 10.00 g of PDCP in 100 mL of THF, pour it into a 500 mL one-necked flask, and then add dropwise 17.98 g of sodium phenoxide (prepared from 14.57 g of phenol and 6.20 g of sodium hydride in 100 mL of THF). Then sti...

Embodiment 1

[0045] 900g of polyethylene adipate with a molecular weight of 2000 and a functionality of 2, 100g of hydroxypolyphosphazene oligomer-1 and 306g of NDI were reacted at 128°C for 1.5 hours to obtain -NCO%=6.25%. Polymer; chain extender compounding components are: 40g 1,4-butanediol, 15g E300 (3,5-dimethylthiotoluenediamine), 9g water, 10g amine tin compound catalyst (triethylene Diamine Dabco 33-LV and dibutyltin dilaurate (T-12)), 15g of amphiphilic silicone oil DC193; using a low-pressure foaming machine, according to the ratio of isocyanic acid index to 1.08, mixed prepolymerized Body and chain extender components, the mixed glue solution is injected into a mold at 80-95°C by a low-pressure foaming machine for molding and pre-cured, demolded after 30 minutes, and then placed in a 120°C blast drying oven for 12 hours of curing.

[0046] The polyurethane microcellular elastomer prepared according to this example was aged at room temperature for about one week to test the mecha...

Embodiment 2

[0053] 930g of polyethylene adipate with a molecular weight of 2500 and a functionality of 2, 70g of hydroxyphosphazene oligomer and 303g of NDI were reacted at 128°C for 1.5 hours to obtain a prepolymer of -NCO%=6.74%; The chain extender compounding components are: 45g 1,4-butanediol, 20g E300 (3,5-dimethylthiotoluenediamine), 9g water, 10g amine tin compound catalyst (triethylene di Compounding of amine Dabco 33-LV and dibutyltin dilaurate (T-12), 15g of amphiphilic silicone oil DC193; using a low-pressure foaming machine, mix the prepolymer and For the chain extender component, the mixed glue solution is injected into a mold at 80-95°C by a low-pressure foaming machine to be formed and pre-cured. After 30 minutes, the mold is demoulded, and then placed in a blast drying oven at 120°C for 12 hours of curing.

[0054] The polyurethane microcellular elastomer prepared according to this example was aged at room temperature for about one week to test the mechanical properties an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com