Method and culture medium for producing riprestatin by microbial fermentation

A technology of microbial fermentation and fermentation medium, which is applied in the field of microbial fermentation to produce riprestatin and medium, which can solve the problems of low fermentation level and achieve the effects of increasing potency, increasing production and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

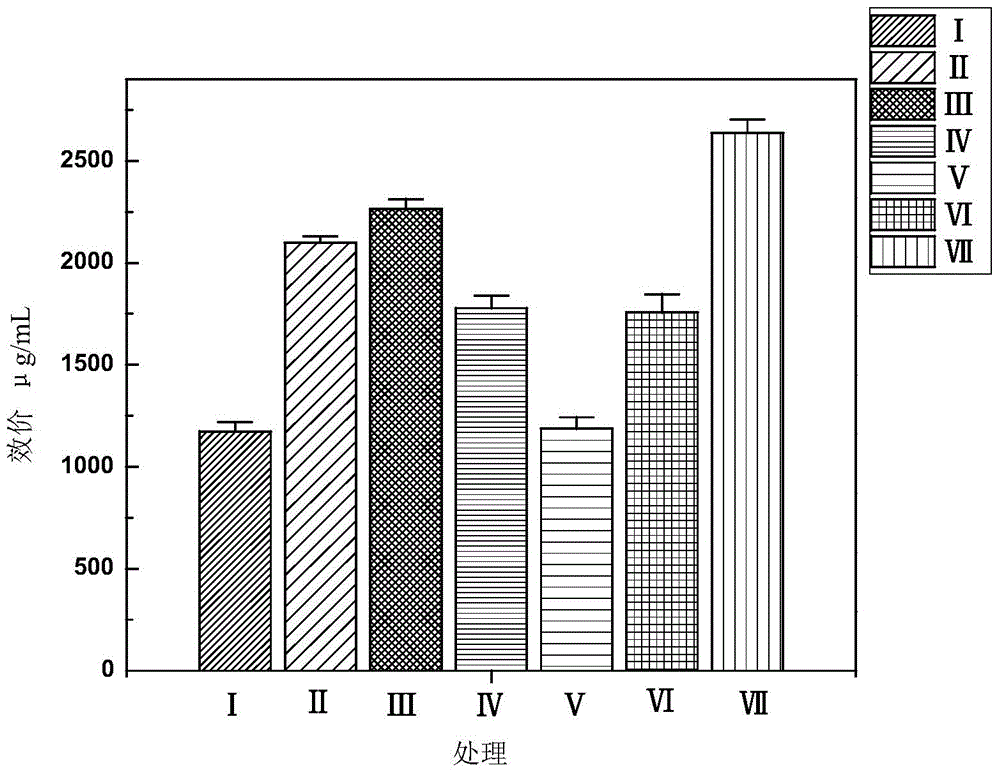

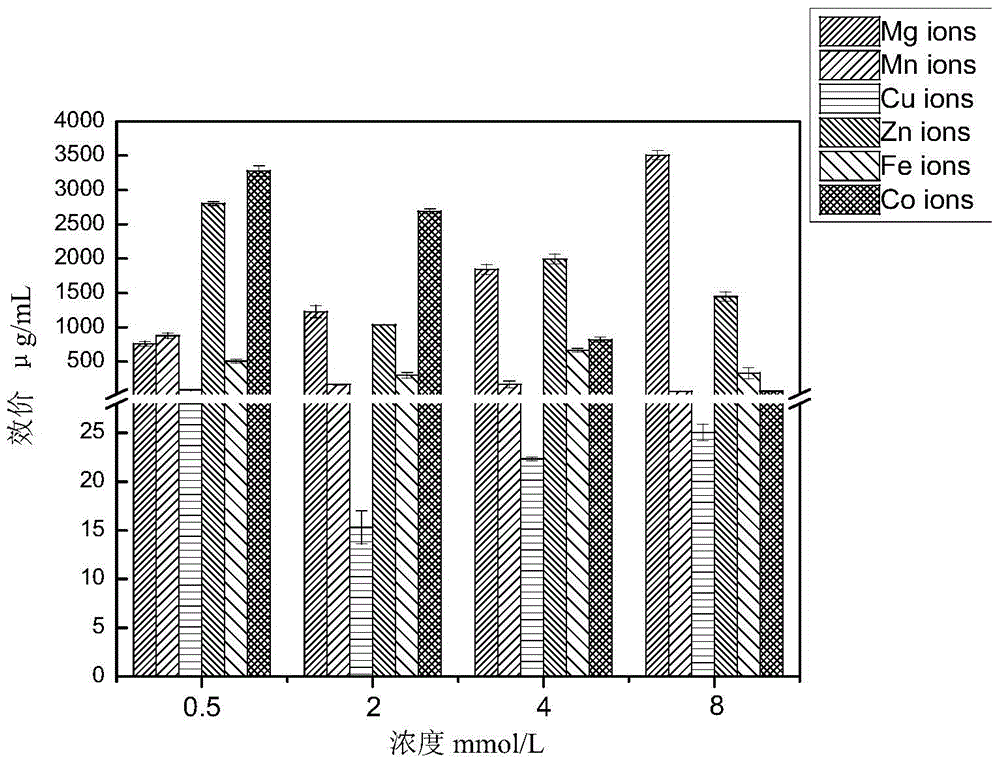

Examples

Embodiment 1

[0020] 1. Strains:

[0021] Stretomycestoxytricini mutant strain XC-lp-69 (provided by Xinchang Pharmaceutical Factory of Zhejiang Pharmaceutical Co., Ltd.).

[0022] 2. Medium:

[0023] Slant medium preparation: soluble starch 10g, wheat flour 5g, yeast extract 1g, casein 1g, potassium dihydrogen phosphate 0.5g, magnesium sulfate 0.5g, agar 20g, add water to dilute to 1L, and adjust pH to 7.1, 121~ Sterilize at 125°C for 20 minutes. This medium is used for strain activation.

[0024] Seed medium preparation: 20g soybean meal powder, 20g glycerin, 5g yeast extract, add water to make the volume to 1L, adjust the pH to 7.1, 121~125℃, and sterilize for 20min. This medium is used for seed liquid preparation.

[0025] Initial fermentation medium: 32.5g soybean meal powder, 8g corn gluten meal, 100g sunflower oil, 25g soybean soft phospholipid, 22.5g glycerin, Tween-800.05g, 0.8g calcium carbonate, 0.025g vitamin E, 0.125g vitamin C, Add water to make the volume to 1L, adjust the pH to 7....

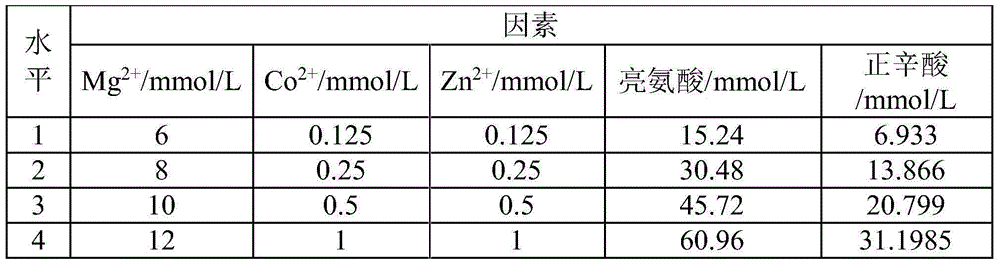

Embodiment 2

[0053] Slant medium preparation: soluble starch 10g, wheat flour 5g, yeast extract 1g, casein 1g, potassium dihydrogen phosphate 0.5g, magnesium sulfate 0.5g, agar 20g, add water to dilute to 1L, and adjust pH to 7.1, 121~ Sterilize at 125°C for 20 minutes. This medium is used for strain activation.

[0054] Seed medium preparation: 20g soybean meal powder, 20g glycerin, 5g yeast extract, add water to make the volume to 1L, adjust the pH to 7.1, 121~125℃, and sterilize for 20min. This medium is used for seed liquid preparation.

[0055] Fermentation medium preparation: 32.5g soybean meal powder, 8g corn gluten meal, 100g sunflower oil, 25g soybean soft phospholipid, 22.5g glycerin, Tween-800.05g, 0.8g calcium carbonate, 0.025g vitamin E, 0.125g vitamin C, MgSO 4 12mmol, CoSO 4 ·7H 2 O1mmol, ZnSO 4 ·7H 2 O0.25mmol, add water to make the volume to 1L, adjust the pH to 7.1, 121~125℃, sterilize for 20min. The medium is used for fermentation production of lipstatin.

[0056] Slant cul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com