Preparation method of transforming yttrium aluminum garnet doped ceramic into single crystal

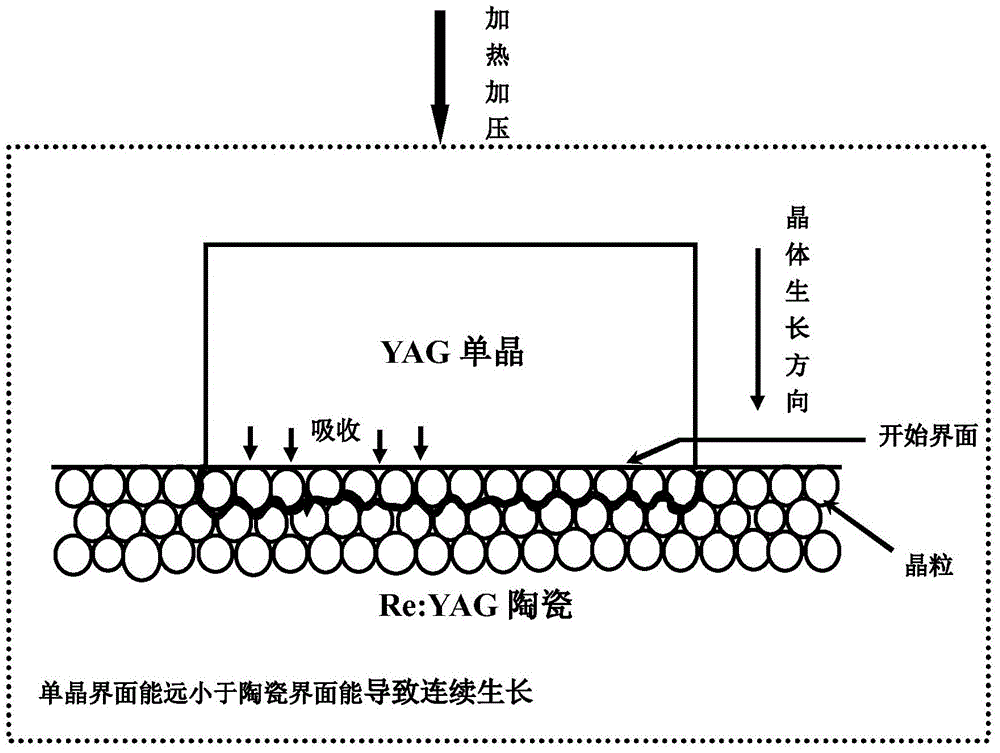

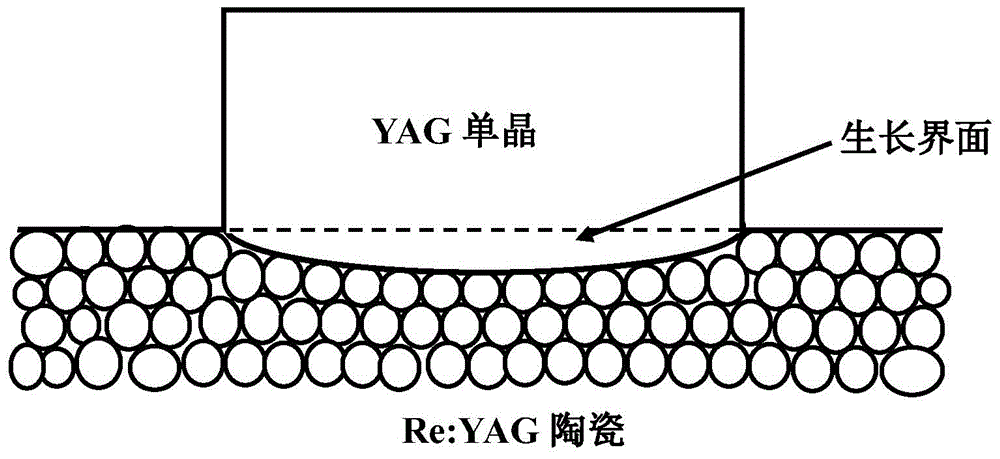

A technology of yttrium aluminum garnet and single crystal, which is applied in the field of single crystal preparation by non-melting method, can solve the problems of uneven composition and low doping, achieve uniform composition, high doping concentration, and increase controllability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

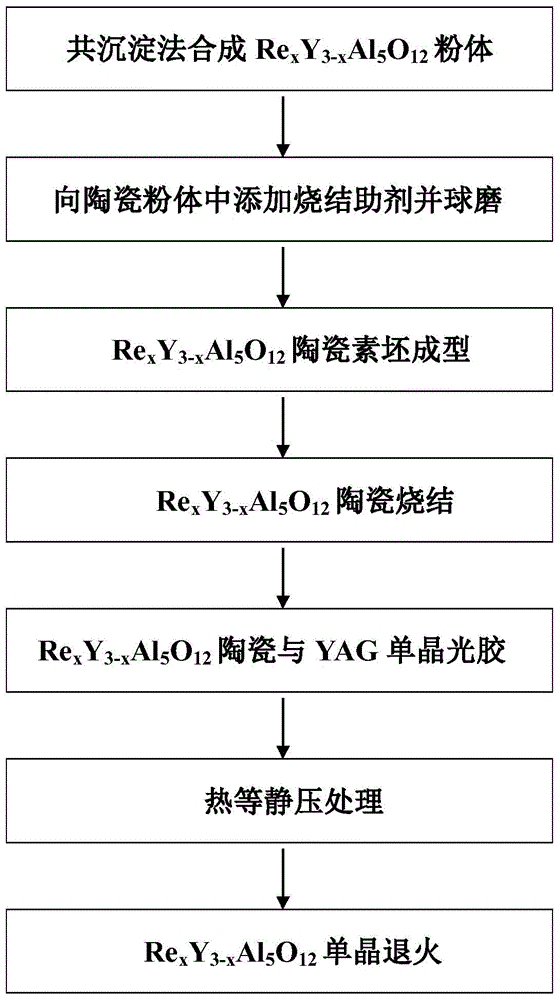

Method used

Image

Examples

Embodiment 1

[0036] Neodymium nitrate hexahydrate (Nd(NO 3 ) 3 ·6H 2 O), yttrium nitrate hexahydrate (Y(NO 3 ) 3 ·6H 2 O), aluminum ammonium sulfate dodecahydrate (NH 4 Al(SO 4 ) 2 12H 2 O) Feedstock, ammonium bicarbonate (NH 4 HCO 3 ) as a precipitant, and the coprecipitation method was used to synthesize Nd 0.06 Y 2.94 Al 5 o 12 The precursor was calcined at 900°C for 2 hours to synthesize highly active and highly dispersed Nd with an average particle size of 20 nm 0.06 Y 2.94 Al 5 o 12 Nano powder. Using 0.14% SiO by powder weight 2 As a sintering aid, it is mixed in Nd by ball milling method 0.06 Y 2.94 Al 5 o 12 Among the powder raw materials, the ball milling medium is high-purity agate balls, and the ball milling solvent is alcohol. The total volume of powder: the volume of agate balls: the volume of alcohol = 1:2:4. After ball milling for 48 hours, the Nd 0.06 Y 2.94 Al 5 o 12 The slurry was poured into a glass flask, and then dried in an oven at 80° C. f...

Embodiment 2

[0042] Erbium nitrate hexahydrate (Er(NO 3 ) 3 ·6H 2 O), yttrium nitrate hexahydrate (Y(NO 3 ) 3 ·6H 2 O), aluminum ammonium sulfate dodecahydrate (NH 4 Al(SO 4 ) 2 12H 2 O) Feedstock, ammonium bicarbonate (NH 4 HCO 3 ) as a precipitant, and the co-precipitation method was used to synthesize Er 0.6 Y 2.4 Al 5 o 12 The precursor was calcined at 1100°C for 2 hours to synthesize highly active and highly dispersed Er with an average particle size of 55 nm. 0.6 Y 2.4 Al 5 o 12 Nano powder; use 0.14% SiO by powder weight 2 and 0.08% MgO as a sintering aid, and mixed in Er 0.6 Y 2.4 Al 5 o 12 Among the powder raw materials, the ball milling medium is high-purity agate balls, and the ball milling solvent is alcohol. The total volume of powder: the volume of agate balls: the volume of alcohol = 1:2:5. After 36 hours of ball milling, the Er 0.6 Y 2.4 Al 5 o 12 The slurry was poured into a glass flask, and then dried in an oven at 80° C. for 120 hours. After th...

Embodiment 3

[0048] With cerium nitrate hexahydrate (Ce(NO 3 ) 3 ·6H 2 O), yttrium nitrate hexahydrate (Y(NO 3 ) 3 ·6H 2 O), aluminum ammonium sulfate dodecahydrate (NH 4 Al(SO 4 ) 2 12H 2 O) Feedstock, ammonium bicarbonate (NH 4 HCO 3 ) as the precipitating agent, the Ce was synthesized by co-precipitation method 0.09 Y 2.91 Al 5 o 12The precursor was calcined at 1300°C for 4 hours to synthesize highly active and highly dispersed Ce with an average particle size of 200 nm 0.09 Y 2.91 Al 5 o 12 Nano powder; use 0.14% SiO by powder weight 2 , 0.08%MgO, and 0.78%LiF are used as sintering aids, and they are mixed in Ce by ball milling 0.09 Y 2.91 Al 5 o 12 Among the powder raw materials, the ball milling medium is high-purity agate balls, and the ball milling solvent is alcohol. The total volume of powder: the volume of agate balls: the volume of alcohol = 1:2:5. After ball milling for 24 hours, the YAG slurry was poured into a glass flask, and then dried in an oven at 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com