Carbon nanometer fiber/ferrite composite absorbing material and preparation method thereof

A composite wave absorbing material and carbon nanofiber technology, applied in the field of wave absorbing materials, can solve the problems of being thin, light, wide and strong, and achieve the elimination of internal stress and lattice defects, good mechanical properties, and easy operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Weigh iron salt and be dissolved in the ethylene glycol of 90wt% concentration, and add zinc salt, wherein Zn 2+ The ratio of the number of moles of Fe3+ to the number of moles of Fe3+ is 1:2, the bacterial cellulose is added for ultrasonic dispersion for 30 minutes, and the mass ratio of the total weight of iron salt and zinc salt to the bacterial cellulose is 1:1;

[0027] and Fe 3+ Anhydrous sodium acetate with a molar ratio of 8:1, a dispersant whose volume accounts for 2% of the volume of ethylene glycol, heated and dissolved at 60°C for 30 minutes, and the mixture was obtained after the powder was completely dissolved;

[0028] Put the above mixture into a reaction kettle and react at 140°C for 15 h. After the reaction is completed, it is naturally cooled to room temperature, washed with deionized water for 2 to 5 times and then dried. The obtained compound is vacuum carbonized in an atmosphere furnace, and the temperature is raised from room temperature To 300°C...

Embodiment 2

[0031] Weigh iron salt and dissolve it in the ethylene glycol of 95wt%, and add magnesium salt and zinc salt, wherein Mg 2+ and Zn 2+ The ratio of the sum of the moles of Fe3+ to the moles of Fe3+ is 1:2, the bacterial cellulose is added for ultrasonic dispersion for 60 minutes, and the mass ratio of the total weight of iron salt, magnesium salt and zinc salt to the bacterial cellulose is 1:0.8 ;

[0032] and Fe 3+ Anhydrous sodium acetate with a molar ratio of 9:1, a dispersant whose volume accounts for 2% of the volume of ethylene glycol, heated and dissolved at 70°C for 25 minutes, and the mixture was obtained after the powder was completely dissolved;

[0033] Put the above mixture into the reaction kettle and react at 150 °C for 13 h. After the reaction was completed, it was naturally cooled to room temperature, washed with deionized water for 2 to 5 times and then dried. The obtained compound was placed in an atmosphere furnace for carbonization under vacuum. Raise th...

Embodiment 3

[0036] Weigh iron salt and be dissolved in the ethylene glycol of 98wt% in concentration, and add nickel salt, zinc salt and copper salt, wherein Ni 2+ , Zn 2+ 、Cu 2+ The sum of moles and Fe 3+ The molar ratio of the bacterial cellulose is 1:2, the bacterial cellulose is added for ultrasonic dispersion for 90 minutes, and the mass ratio of the total weight of the iron salt, nickel salt, zinc salt and copper salt to the bacterial cellulose is 1:0.6;

[0037] and Fe 3+ Anhydrous sodium acetate with a molar ratio of 10:1, a dispersant whose volume accounts for 3% of the volume of ethylene glycol, heated and dissolved at 80°C for 20 minutes, and the mixture was obtained after the powder was completely dissolved;

[0038]Put the above mixture into the reaction kettle and react at 160 °C for 10 h. After the reaction is completed, it is naturally cooled to room temperature, washed with deionized water for 2 to 5 times, and then dried. The obtained compound is placed in an atmosphe...

PUM

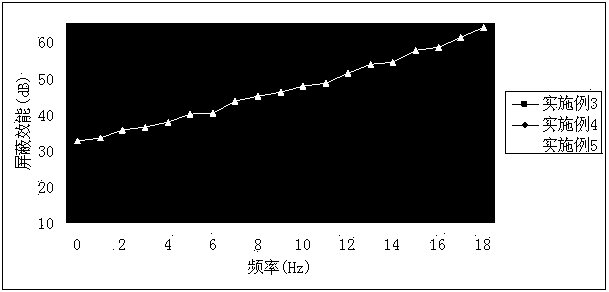

| Property | Measurement | Unit |

|---|---|---|

| Electromagnetic shielding effectiveness | aaaaa | aaaaa |

| Electromagnetic shielding effectiveness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com