A kind of using poultry egg shells as calcium source to prepare glutamic acid chelated calcium and its preparation method

A technology for chelating calcium glutamic acid and poultry egg shells, which is applied in chemical instruments and methods, cyanide reaction preparation, preparation of organic compounds, etc., can solve the problems of affecting the health of users, residual organic solvents, poor solubility and the like, Achieving the effect of highlighting the calcium absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment one: Adopt poultry eggshell to prepare glutamic acid chelated calcium as calcium source

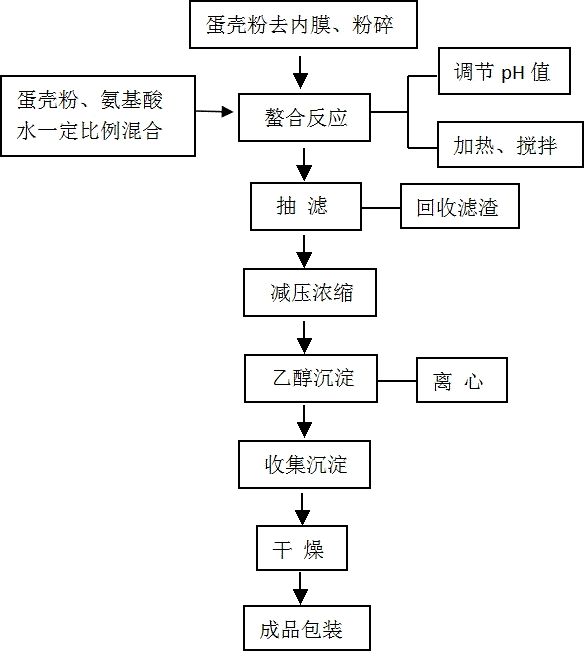

[0030] The specific steps of the method for directly preparing glutamic acid chelated calcium by using poultry eggshells as a calcium source are as follows.

[0031] (1) Raw material pretreatment: After collecting poultry eggshells, wash the surface debris with clean water, boil in boiling water for 5-10 minutes, 40-60kHz, ultrasonic 20-30min for the first shell membrane separation, put it in a tunnel type blast drying box and use wind force Separate the shell membrane again, crush it through a 100-mesh sieve to obtain eggshell powder with high purity, and store it at 4°C for later use.

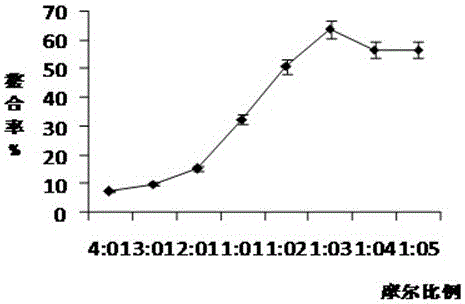

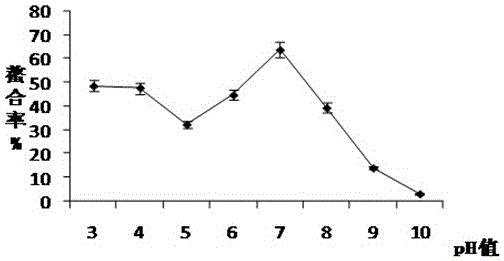

[0032] (2) Mix eggshell calcium powder and glutamic acid at a molar ratio of 1:2 to 1:3, add distilled water at a solid-to-liquid mass ratio of 1:15 to 1:20, adjust the pH value to 6-8 with NaOH, and heat Stir at 60-80°C at a speed of 20-30r / min to keep warm and chelate for 50-70min. ...

Embodiment 2

[0036] Embodiment two: Adopt poultry eggshell to prepare glutamic acid chelated calcium as calcium source

[0037] The specific steps of the method for directly preparing glutamic acid chelated calcium by using poultry eggshells as a calcium source are as follows.

[0038] (1) Raw material pretreatment: After collecting poultry eggshells, wash the surface debris with clean water, boil in boiling water for 5 minutes, 40kHz, and ultrasonically separate the shell and membrane for 20 minutes. 100-mesh sieve to obtain eggshell powder with higher purity, and then store it at 4°C for later use.

[0039] (2) Mix eggshell calcium powder and glutamic acid at a molar ratio of 1:2, add distilled water at a solid-to-liquid mass ratio of 1:15, adjust the pH value to 6 with NaOH, heat to 60°C and keep stirring at a speed of 20r / min Chelation 50min.

[0040] (3) The crude product of the chelation reaction obtained in the above steps is suction-filtered for 5 minutes, and the filter residue ...

Embodiment 3

[0043] Embodiment three: Adopt poultry eggshell to prepare glutamic acid chelated calcium as calcium source

[0044] The specific steps of the method for directly preparing glutamic acid chelated calcium by using poultry eggshells as a calcium source are as follows.

[0045] (1) Raw material pretreatment: After collecting poultry eggshells, wash the surface debris with clean water, boil in boiling water for 10 minutes, 60kHz, and ultrasonic for 30 minutes to separate the shell and membrane for the first time. 100-mesh sieve to obtain eggshell powder with higher purity, and then store it at 4°C for later use.

[0046] (2) Mix eggshell calcium powder and glutamic acid at a molar ratio of 1:3, add distilled water at a solid-to-liquid mass ratio of 1:20, adjust the pH value to 8 with NaOH, heat to 80°C and keep stirring at a speed of 30r / min Chelation 70min.

[0047] (3) The crude product of the chelation reaction obtained in the above steps is suction-filtered for 10 minutes, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com