Cu (I) coordination polymer green light emitting material and synthesis method thereof

A technology of coordination polymers and luminescent materials, applied in luminescent materials, copper organic compounds, chemical instruments and methods, etc., can solve the problems of concentration quenching, poor thermal stability, decreased fluorescence lifetime, etc. The raw materials are cheap and easy to obtain, and the effect of excellent luminescence performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] A kind of synthetic method of Cu (I) coordination polymer green luminescent material, comprises the following steps:

[0025] a. Take the organic ligand 4-(5-sulfonyl) 8-hydroxyquinolyl-phthalic acid and dissolve it in the mixed solution of water and organic solvent to obtain solution A;

[0026] The organic solvent is DMF, methanol or propanol, and the volume ratio of water to the organic solvent is 0.5:1.2 to 0.5:2.5. The addition amount of the organic ligand and the mixed solution is as follows: 0.1-0.5 mmol of the organic ligand is added for every 20-50 ml of the mixed solution.

[0027] b. Take Cu(OAc) 2 h 2 Add O and 4,4'-bipyridine into solution A, and stir to obtain solution B; Cu(OAc) 2 h 2 The amount of O, 4,4'-bipyridine and solution A added is: add 0.01~0.1mmol Cu(OAc) per 10~50ml of solution A 2 h 2 O and 0.05-0.15 mmol of 4,4'-bipyridine.

[0028] c. Stir solution B with a magnetic stirrer at room temperature and pressure for 10-30 minute...

Embodiment 1

[0031] A kind of synthetic method of Cu (I) coordination polymer green luminescent material, comprises the following steps:

[0032] Raw materials: 4-(5-sulfonyl)8-hydroxyquinoline-phthalic acid, glacial acetic acid, N,N-diformamide (DMF), concentrated hydrochloric acid, copper acetate monohydrate, NaOH, 4,4-bipyridine, All are analytically pure, respectively supplied by Shanghai Sinopharm Corporation, Tianjin Damao Corporation, Jinan Henghua Technology Co., Ltd., Tianjin Chemical Reagent Factory, Luoyang Chemical Reagent Company, and Beijing Fontes Chemical Materials Co., Ltd.

[0033] The synthetic route of 4-(5-sulfonyl) 8-hydroxyquinoline-phthalic acid is as follows:

[0034]

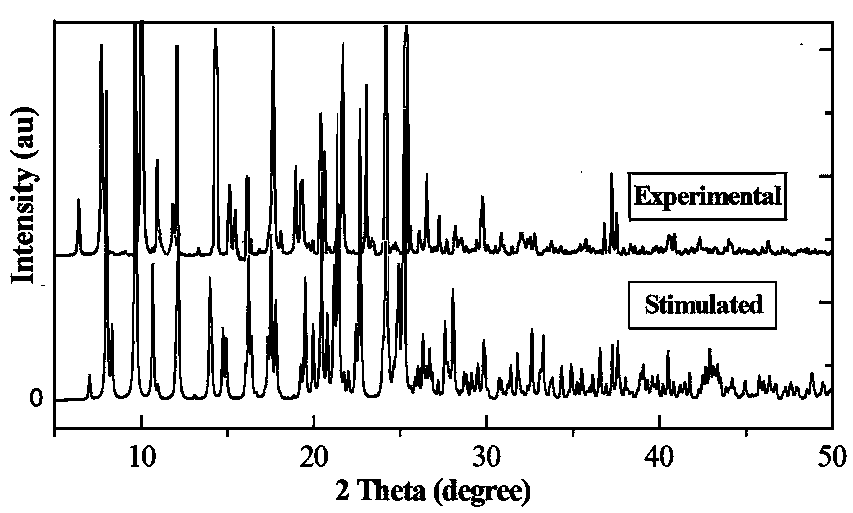

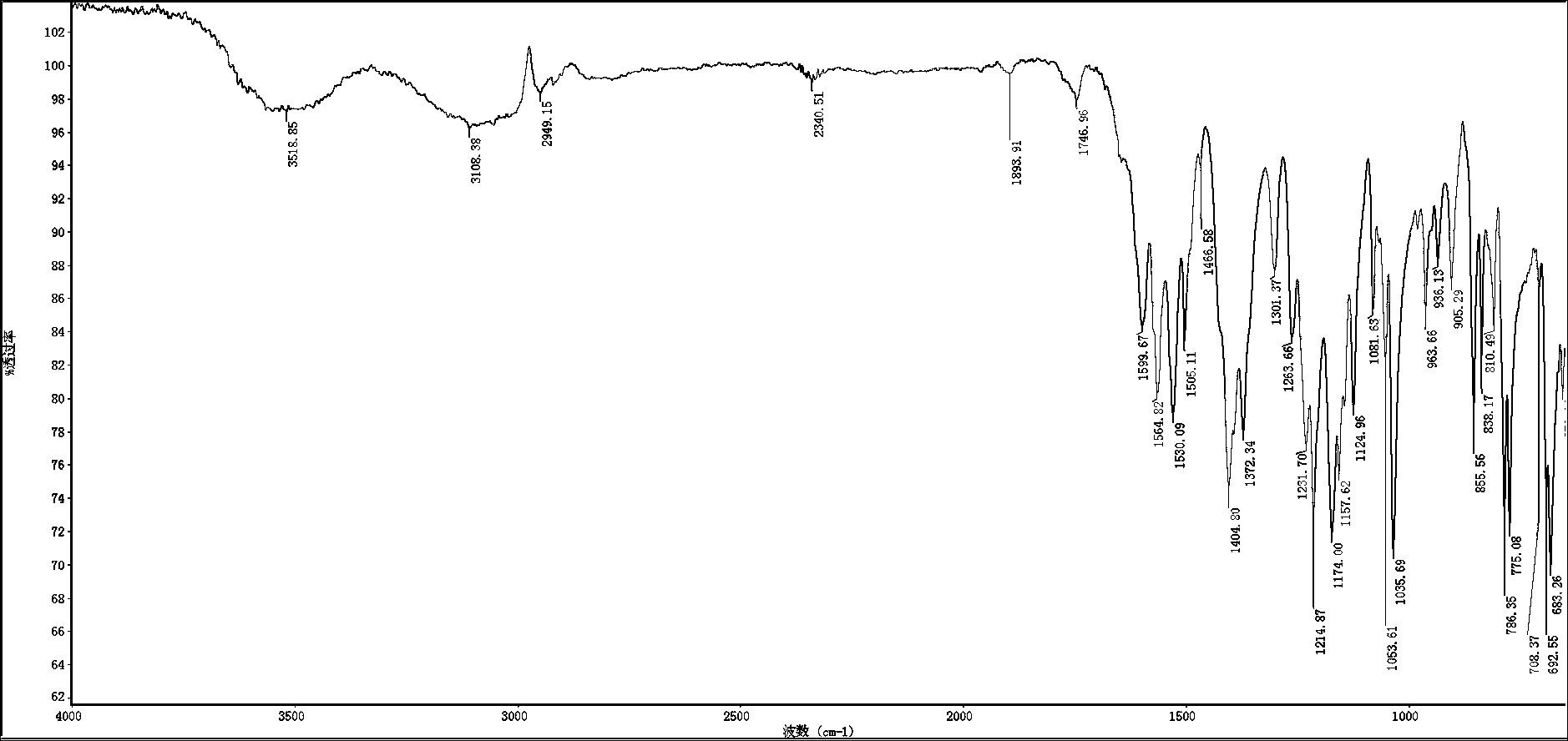

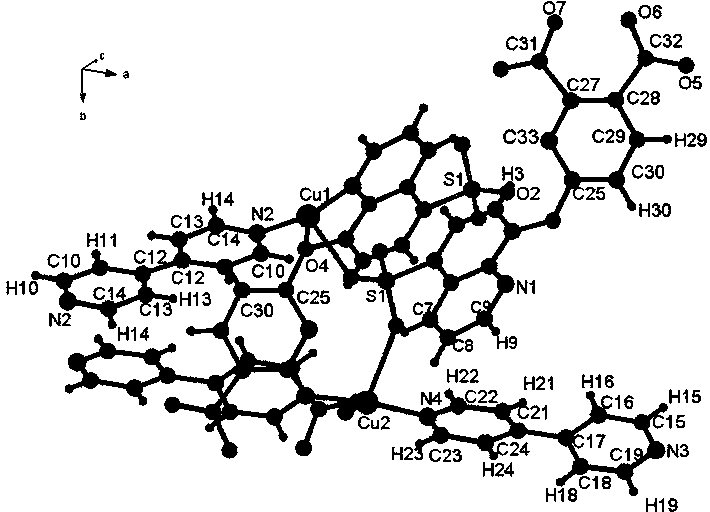

[0035]Magnetic heating and stirring electric heating mantle, electronic analytical balance, Fourier transform infrared spectrometer, Avater370; CNC ultrasonic cleaner, circulating water vacuum pump (Zhengzhou Dufu Instrument Co., Ltd.), melting point tester, rotary evaporation instrument, X-ray s...

Embodiment 2

[0051] A kind of synthetic method of Cu (I) coordination polymer green luminescent material, comprises the following steps:

[0052] a. Dissolve 0.1 mmol of the organic ligand 4-(5-sulfonyl) 8-hydroxyquinolyl-phthalic acid in a mixture of 40 ml of water and DMF (volume ratio of water to methanol is 1:4), Obtain solution A;

[0053] b. Take 0.1 mmol of Cu(OAc) 2 h 2 O and 0.05mmol of 4,4'-bipyridine were added to 10ml of solution A, and after stirring evenly, solution B was obtained;

[0054] c. Stir solution B with a magnetic stirrer at room temperature and pressure for 10 minutes, then add dilute HNO 3 , adjust the pH value to 6.0, obtain the precursor solution C, and set aside;

[0055] d. Transfer the precursor solution C to a polytetrafluoroethylene-lined hydrothermal reaction kettle, seal the reaction kettle, put the reaction kettle into an oven, and select the temperature control mode to react. The temperature is controlled at 140°C. After 90 hours of re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| emission peak | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com