Preparation method of carrying type laminated hydroxyl magnesium oxide composite material

A technology of magnesium oxyhydroxide and composite materials, which is applied in the field of preparation of phosphate materials for purifying biochemical tail water, can solve problems such as poor kinetic performance, small size characteristics of nanoparticles, easy agglomeration or growth, etc., so as to solve the problem of poor kinetic performance. , the effect of large adsorption capacity and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

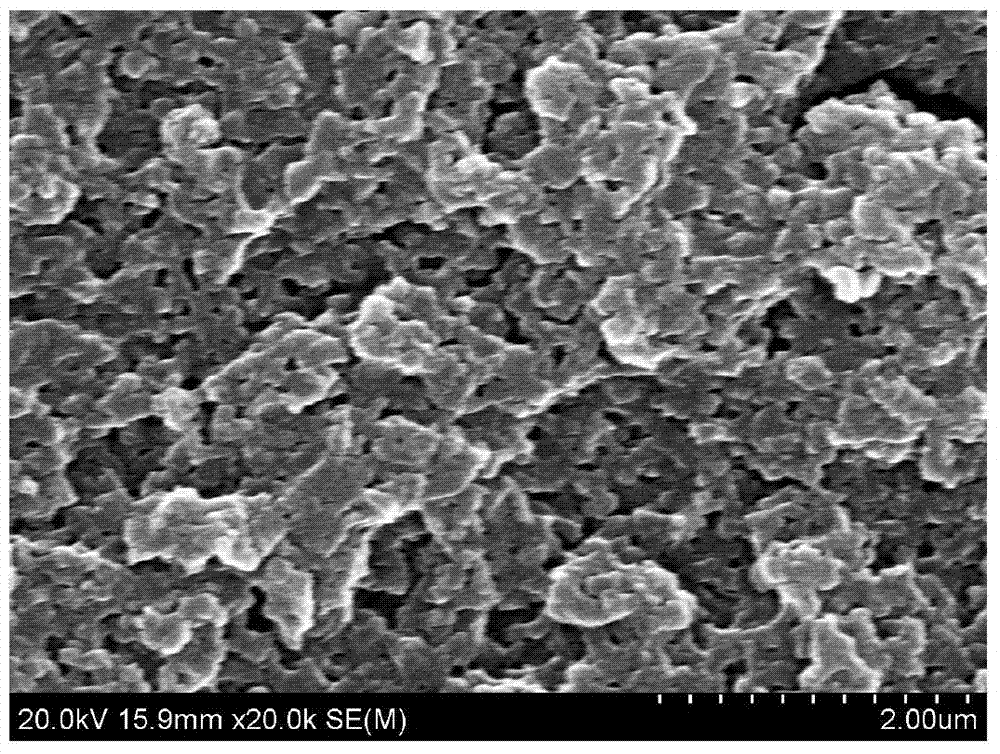

[0023] Measure 25g of D201 type anion exchange resin (produced by Hangzhou Zhengguang Industrial Co., Ltd., the same below) as a carrier material, place it in 2.5L aqueous solution containing 5% magnesium nitrate, control the reaction temperature at 40°C, fully stir the reaction for 10h, The Mg is gradually diffused to the inner surface of the anion exchange resin pores. Then the resin was filtered and placed in 1500mL of 3% sodium hydroxide solution for in-situ precipitation reaction at room temperature, the precipitation reaction time was controlled to be 10h, after the reaction was completed, it was filtered and heat-treated at 40°C for 5h to obtain the Supported magnesium oxyhydroxide composite materials, such as figure 1 As shown, its loading is 5.9%.

[0024] Put 5mL of the above composite material in a glass adsorption column (ф12×220mm) 4 2- =200mg / L, Cl - =100mg / L,NO 3 - =160mg / L, pH=5) Flow through the adsorption column equipped with composite material from top...

Embodiment 2

[0026] Take 50g of 201x7 type anion exchange resin (manufactured by Tianjin Bohong Resin Technology Co., Ltd.) as a carrier material, place it in 1600mL of 40% magnesium chloride aqueous solution, control the reaction temperature at 60°C, fully stir the reaction for 12 hours, so that Mg can gradually diffuse to the inner surface of the anion exchange resin pores. Then the resin was filtered and placed in 2000mL of 8% sodium hydroxide solution for in-situ precipitation reaction at room temperature, the precipitation reaction time was controlled to be 12h, and after the reaction was completed, it was filtered and heat-treated at 60°C for 8h to obtain the The loaded magnesium oxyhydroxide composite material has a loading capacity of 21.8%.

[0027] Put 30mL of the above composite material in a glass adsorption column (ф20×420mm) and phosphate-containing surface water (P=2mg / L and SO 4 2-=180mg / L, Cl-=200mg / L, NO 3 - =220mg / L, pH=10) Flow through the adsorption column equipped...

Embodiment 3

[0029] Measure 20 g of 717-type anion exchange resin (produced by Nanda Resin Factory in Langfang, Hebei Province) as a carrier material, place it in 400 mL of 30% magnesium nitrate solution, control the reaction temperature at 50 ° C, and fully stir the reaction for 11 hours to make Mg gradually diffuse to The inner surface of the pores of anion exchange resin. Then the resin was filtered and placed in 1500mL of 6% sodium hydroxide solution for in-situ precipitation reaction at room temperature, the precipitation reaction time was controlled to be 11h, after the reaction was completed, it was filtered and heat treated at 50°C for 6h to obtain the The loaded magnesium oxyhydroxide composite material has a loading capacity of 18.9%.

[0030] Put 20mL of the above composite material in a glass adsorption column (ф20×420mm) and phosphate-containing wastewater (P=3mg / L and SO 4 2- =150mg / L, Cl - =220mg / L,NO 3 - =240mg / L, pH=6) Flow through the adsorption column equipped with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com