Solar energy back panel and preparation method thereof

A solar back sheet, surface layer technology, applied in chemical instruments and methods, lamination, photovoltaic power generation, etc., can solve the problems of poor cold resistance, low water vapor, low water absorption, etc., to achieve consistent rheology and process selectivity, low Effect of water vapor transmission rate and low saturated water absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

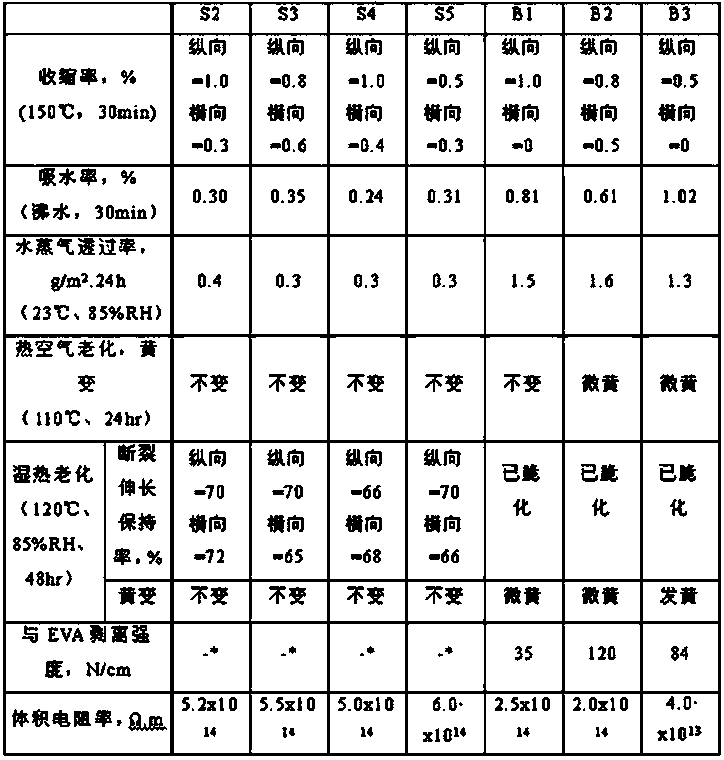

Examples

Embodiment 1

[0038] A method for preparing a solar backboard, comprising the steps of:

[0039](1) Add 10 parts of titanium dioxide R960 and 0.3 parts of silane coupling agent KH560 into a high mixer, stir for 30 minutes at a speed of 600 rpm; then add 100 parts of high-density polyethylene 5000S, 0.2 parts of antioxidant four [ ?-(3',5'-di-tert-butyl-4'-hydroxyphenyl) propionate] pentaerythritol ester (Beijing Institute of Addition Auxiliaries, KY1010), 0.2 parts of UV absorber 2-hydroxy-4- N-octyloxybenzophenone (Beijing Institute of Addition Auxiliaries, GW531), 0.1 part of light stabilizer bis(2,2,6,6-tetramethyl-4-piperidinyl) sebacate ( Beijing Addition Auxiliary Research Institute, GW480), stirring for 30 minutes, the speed is 600 rpm, and the materials are mixed evenly; the above materials are put into the A screw of the three-layer co-extrusion sheet unit, the diameter of the screw is 60 mm, the long diameter than 33;

[0040] (2) Add 10 parts of titanium dioxide R960 (DuPont, U...

Embodiment 2

[0050] A method for preparing a solar backboard, comprising the steps of:

[0051] (1) Add 10 parts of titanium dioxide R960 and 0.3 parts of silane coupling agent KH560 into a high mixer, stir for 30 minutes at a speed of 600 rpm; then add 100 parts of EVA resin 14-2 (Beijing Organic Chemical Factory), 0.2 Part of antioxidant tetrakis[?-(3',5'-di-tert-butyl-4'-hydroxyphenyl)propionate]pentaerythritol ester, 0.2 part of UV absorber 2-hydroxy-4-n-octyloxydi Benzophenone, 0.1 part of light stabilizer bis(2,2,6,6-tetramethyl-4-piperidinyl) sebacate, stirred for 30 minutes at a speed of 600 rpm, and mixed the materials evenly; The above materials are put into the A screw of the three-layer co-extrusion sheet unit, the diameter of the screw is 60 mm, and the aspect ratio is 33;

[0052] (2) Add 10 parts of titanium dioxide R960 (DuPont, USA) and 0.3 parts of silane coupling agent KH560 (Danyang Organosilicon Material Industry Co., Ltd.) into a high mixer, stir for 30 minutes at a ...

Embodiment 3

[0058] A method for preparing a solar backboard, comprising the steps of:

[0059] (1) Add 10 parts of titanium dioxide R960 and 0.3 parts of silane coupling agent KH560 into a high mixer, stir for 30 minutes at a speed of 600 rpm; then add 100 parts of high-density polyethylene 5000S, 0.2 parts of antioxidant four [ ?-(3',5'-di-tert-butyl-4'-hydroxyphenyl) propionate] pentaerythritol ester, 0.2 parts of UV absorber 2-hydroxy-4-n-octyloxybenzophenone, 0.1 parts Light stabilizer bis(2,2,6,6-tetramethyl-4-piperidinyl) sebacate, stir for 30 minutes, rotate at 600 rpm, mix the materials evenly; put the above materials into three layers The A screw of the extrusion sheet unit has a screw diameter of 60 mm and a length-to-diameter ratio of 33;

[0060] (2) Add 10 parts of titanium dioxide R960 (DuPont, USA) and 0.3 parts of silane coupling agent KH560 (Danyang Organosilicon Material Industry Co., Ltd.) into a high mixer, stir for 30 minutes at a speed of 600 rpm; then process Good...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| The melt flow rate | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com