A gallium oxide heterojunction structure and its growth method and special device

A growth method and a heterojunction technology are applied to the nanoscale gallium oxide heterojunction structure, the gallium oxide heterojunction structure and its growth field, and can solve the problems of the complicated nanometer gallium oxide material and the difficulty in obtaining the heterojunction structure, etc. Achieve the effect of uniform size, high growth yield and huge specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

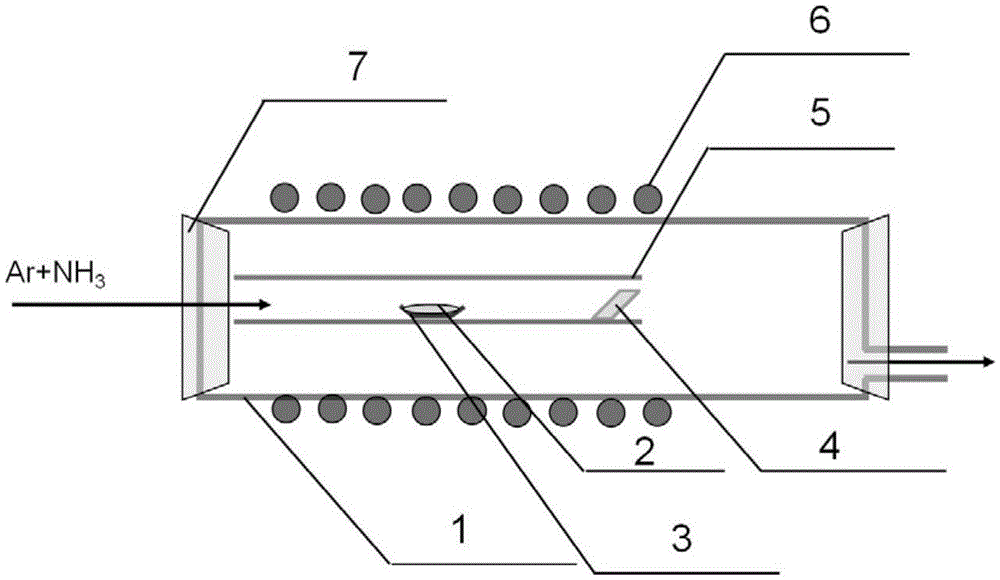

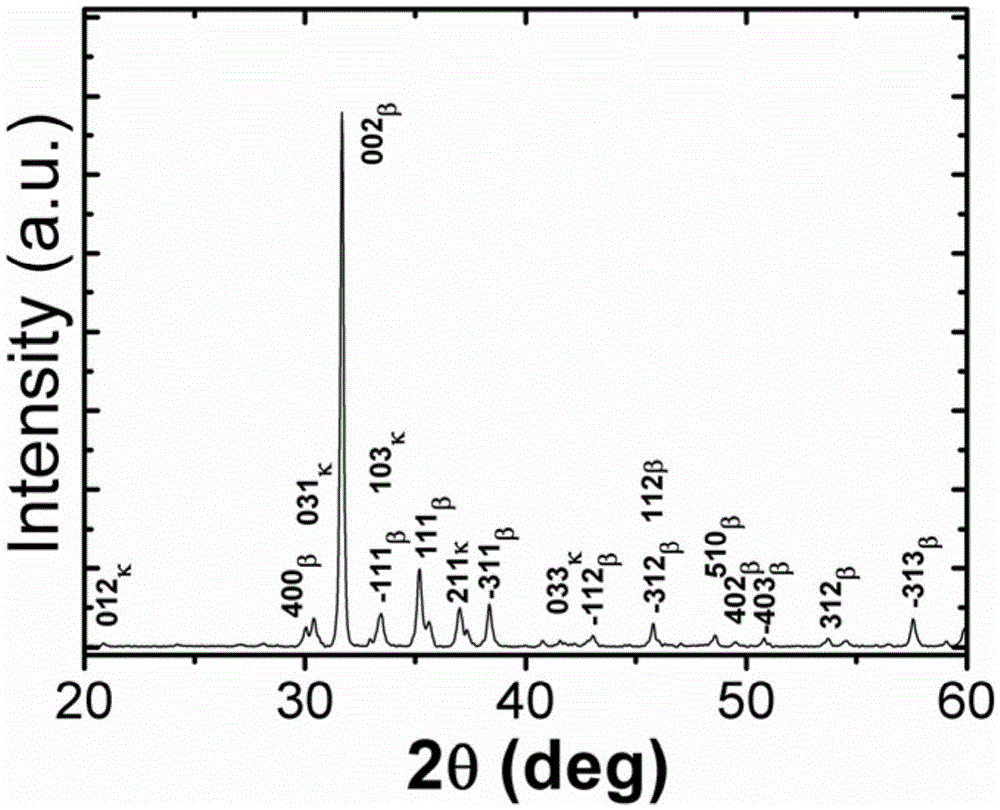

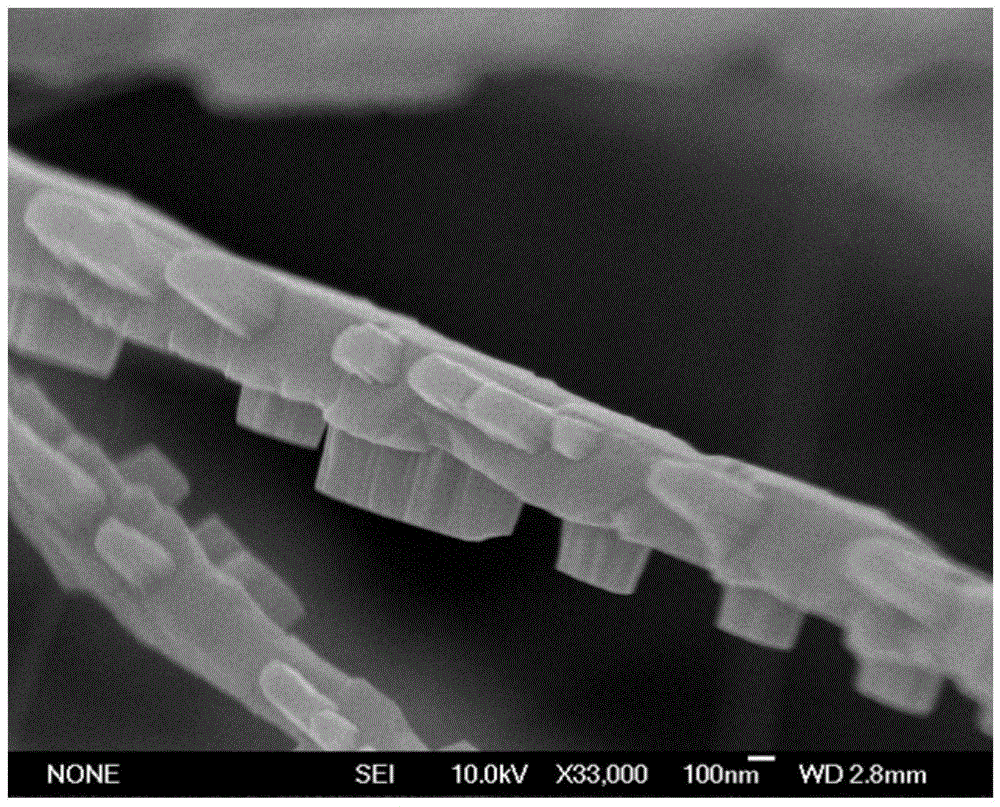

[0044] This embodiment is directly deposited and grown k-Ga on the surface of Si sheet 2 o 3 / β-Ga 2 o 3 The heterojunction structure is as follows:

[0045] 1. Weigh a certain mass of β-Ga 2 o 3 Powder, filled with 1 / 2 volume of β-Ga in alumina ceramic boat 2 o 3 Powder, used β-Ga 2 o 3 The purity is 99.99wt%; then the alumina ceramic boat is placed in the center of the quartz tube, and a silicon wafer is placed as a substrate at 25-35 cm downstream of the quartz tube for the deposition and growth of gallium oxide nanostructures. In this embodiment, the silicon wafer used has a purity of >99.99wt%, a surface crystal orientation of , single-sided grinding, a surface roughness (Ra)≦0.3nm, a surface size of 20×20mm, and a thickness of 0.5mm.

[0046] 2. Use a mechanical pump to pump the air pressure in the quartz tube to 10 -2 Pa, into the quartz tube in step 1, the flow rate is 200 sccm of argon gas for 30 minutes to normal pressure, and the residual gas in the quartz ...

Embodiment 2

[0058] The difference from Example 1 is that this example directly deposits and grows k-Ga on the surface of Si sheet 2 o 3 / β-Ga 2 o 3 The heterojunction structure is as follows:

[0059] 1. Weigh a certain mass of β-Ga 2 o 3 Powder, filled with 1 / 2 volume of β-Ga in alumina ceramic boat 2 o 3 Powder, used β-Ga 2 o 3 The purity is 99.99wt%; then the alumina ceramic boat is placed in the center of the quartz tube, and a silicon wafer is placed 25-30 cm downstream of the quartz tube as a substrate for the deposition and growth of gallium oxide nanostructures. In this embodiment, the silicon wafer used has a purity of >99.99wt%, a surface crystal orientation of , single-sided grinding, a surface roughness (Ra)≦0.3nm, a surface size of 20×20mm, and a thickness of 0.5mm.

[0060] 2. Use a mechanical pump to pump the air pressure in the quartz tube to 10 -3 Pa, into the quartz tube in step 1, the flow rate is 100 sccm of argon gas for 40 minutes to normal pressure, and th...

Embodiment 3

[0070] The difference from Example 1 is that this example directly deposits and grows k-Ga on the surface of Si sheet 2 o 3 / β-Ga 2 o 3 The heterojunction structure is as follows:

[0071] 1. Weigh a certain mass of β-Ga 2 o 3 Powder, filled with 1 / 2 volume of β-Ga in alumina ceramic boat 2 o 3 Powder, used β-Ga 2 o3 The purity is 99.99wt%; then the alumina ceramic boat is placed in the center of the quartz tube, and a silicon wafer is placed 30-35 cm downstream of the quartz tube as a substrate for the deposition and growth of gallium oxide nanostructures. In this embodiment, the silicon wafer used has a purity of >99.99wt%, a surface crystal orientation of , single-sided grinding, a surface roughness (Ra)≦0.3nm, a surface size of 20×20mm, and a thickness of 0.5mm.

[0072] 2. Use a mechanical pump to pump the air pressure in the quartz tube to 10 -1 Pa, into the quartz tube in step 1, the flow rate is 150 sccm of argon for 30 minutes to normal pressure, and the resi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com