Tin-indium alloy coated copper wire and production method thereof

A technology of tin-indium alloy and production method, which is applied to the production of plated copper wire and the field of tin-indium alloy plated copper wire, can solve the problems of uneven thickness of the coating, environmental pollution, unsmooth appearance of the coating, etc. Uniformity, improved cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

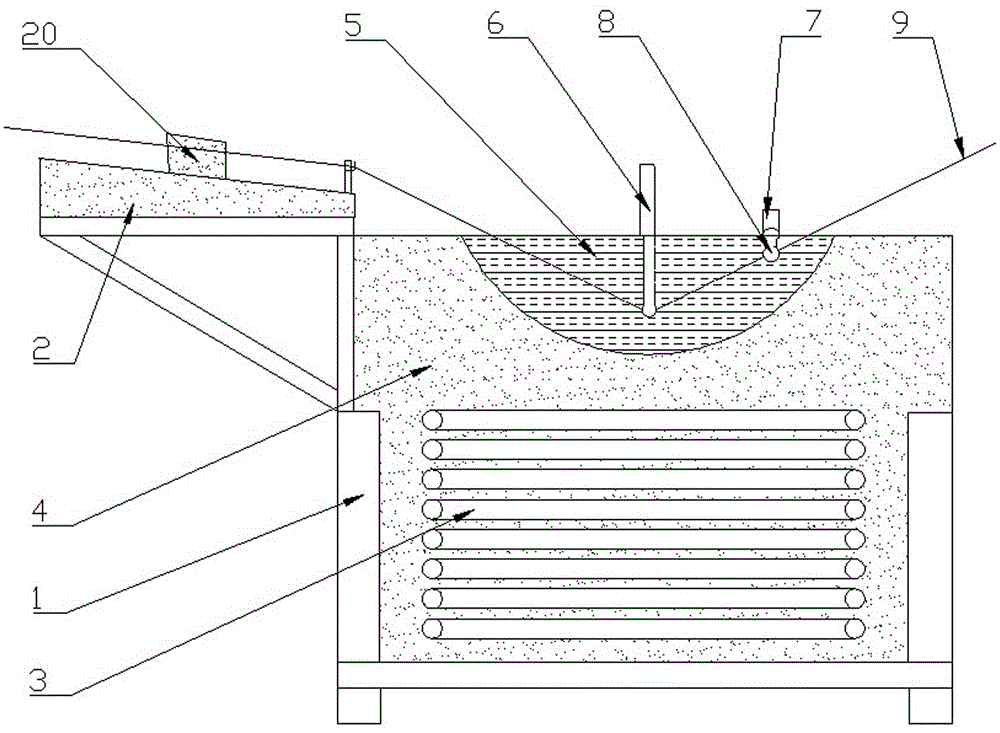

[0029] The production method of the tin-indium alloy plated copper wire of the present embodiment comprises the following steps:

[0030] A. Make copper rods. The copper rod is made of oxygen-free copper with a copper content of more than 99.98%.

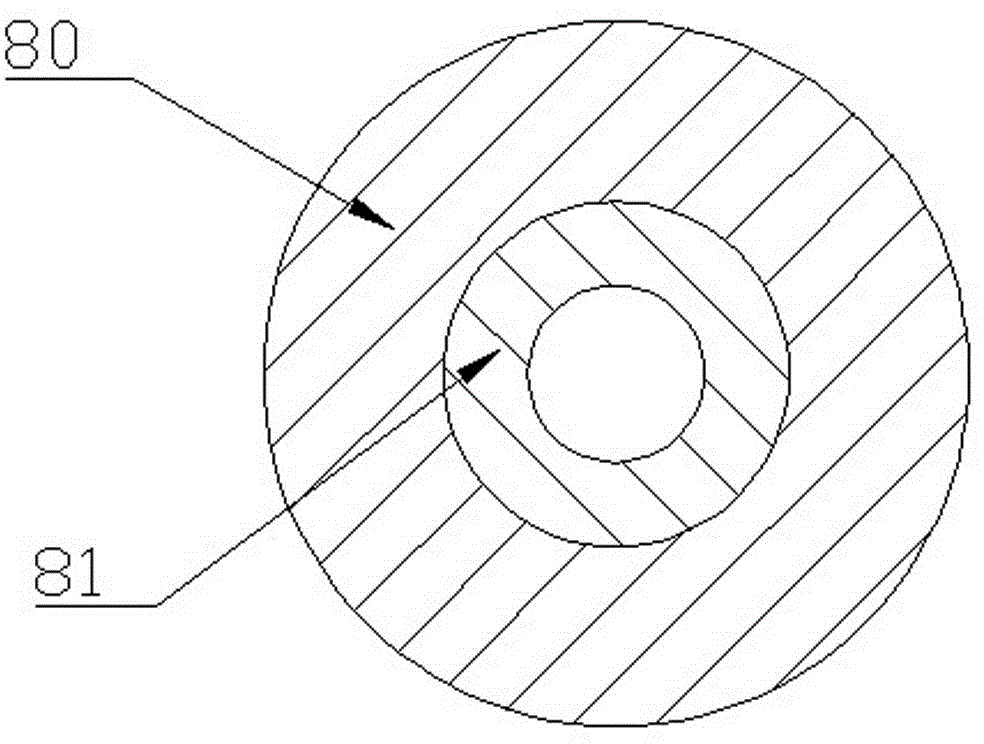

[0031] B. Drawing the above-mentioned copper rod through a wire drawing machine to obtain an oxygen-free copper wire core; the cross-section of the wire core and the finally prepared alloy-coated copper wire is approximately circular.

[0032] In this step, the area reduction rate of the wire drawing die is 13% to 17%, the line speed is 2000 m / min to 2500 m / min, the wire drawing die adopts a polycrystalline diamond die, and its compression angle is 18 ○ ±2 ○ , and the sizing length is 40% ± 10%; in the present embodiment, the lubricating liquid formulation adopted in the drawing process is as follows: 15% modified castor oil, 15% modified sunflower oil, 10% sodium petroleum sulfonate, isothiazole Linone 1‰, triethanolamine 3%, be...

Embodiment 2

[0048] In this example, the lubricating fluid formula used in the drawing process is as follows: 18% modified castor oil, 10% modified sunflower oil, 8% sodium petroleum sulfonate, 1‰ isothiazolinone, 3% triethanolamine, benzene Paratriazole 0.4%, benzene 3%, caustic soda 7%, and the balance is refined machinery oil. All the other production techniques are with embodiment one.

[0049] The tin-indium alloy coated copper wire produced by the present invention reaches the following indicators after testing:

[0050] Comparison table of physical and chemical performance parameters

[0051] Test items Detection method Silver plated soft round copper wire Tinned soft round copper wire Product of the present invention Elongation % GB / T4909.3-2009 20 15 20 ResistivityΩmm2 / m GB / T3048.2-2007 0.017241 0.01770 0.01732 Plating Continuity GB / T4909.9-2009 sodium polysulfide method or ammonium persulfate method Better than required meet the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com