Preparation method of High-temperature water base fracturing fluid

A high-temperature, fracturing fluid technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problem of difficulty in realizing large-scale fracturing construction operations at sea, limited fresh water carried by work vessels, and fracturing vessel docking time. To ensure the effect of fracturing stimulation, improve the effect of fracturing stimulation, and facilitate the recovery of permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] Preparation of thickener

[0025] 2-acrylamide-2-methylpropane sulfonate, acrylamide, dimethyl diallyl ammonium chloride and methacryloyloxyethyl trimethyl ammonium chloride in a mass ratio of 15:40:8 : 5 to make a 30% aqueous solution, keep the temperature at 60°C, fill with nitrogen for 30 minutes, add a redox system (ammonium persulfate: bisulfite = 1:2) and react for 8 hours to obtain a highly viscous transparent jelly , dried and crushed to obtain a thickener.

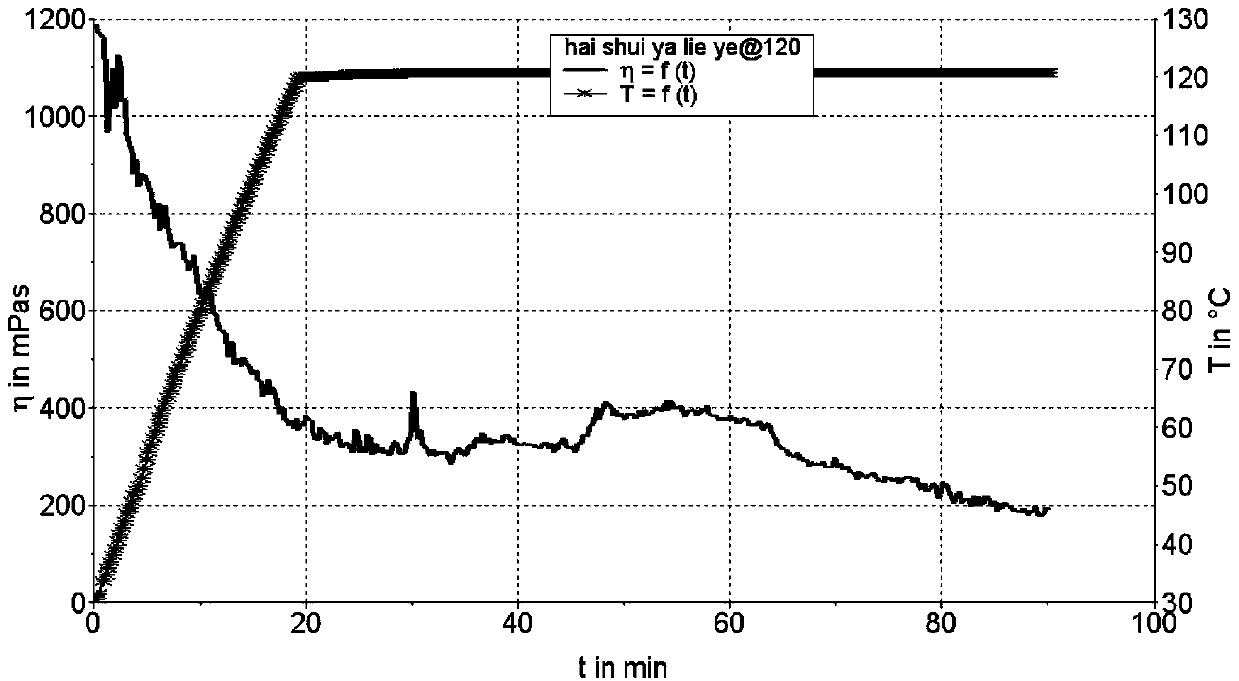

Embodiment 1

[0027] Pour 972.7 parts of seawater taken from the CB326 platform in the Shengli Sea Area of Bohai Bay into the Wuyin mixer, start stirring, and adjust the speed (about 600r / min); slowly add 5 parts of thickener into the seawater, Stir for 10 minutes; add 6 parts of clay stabilizer and 10 parts of drainage aid, continue to stir for 15 minutes to make the thickener swell completely; continue to stir, add 0.3 parts of gel breaker, and then slowly add 6 parts of crosslinking agent until the vortex When it disappears and the liquid level rises slightly, stop stirring, and the finished product of high-temperature-resistant seawater-based fracturing fluid will be formed.

[0028] The cross-linking agent is prepared by zirconium oxychloride, chromium chloride, glycerin and water according to the mass ratio of 5:0.2:0.6:60.

[0029] The demulsification aid is made of polyoxyethylene alkyl alcohol ether nonionic surfactant, fluorocarbon surfactant, quaternary ammonium salt surfactant...

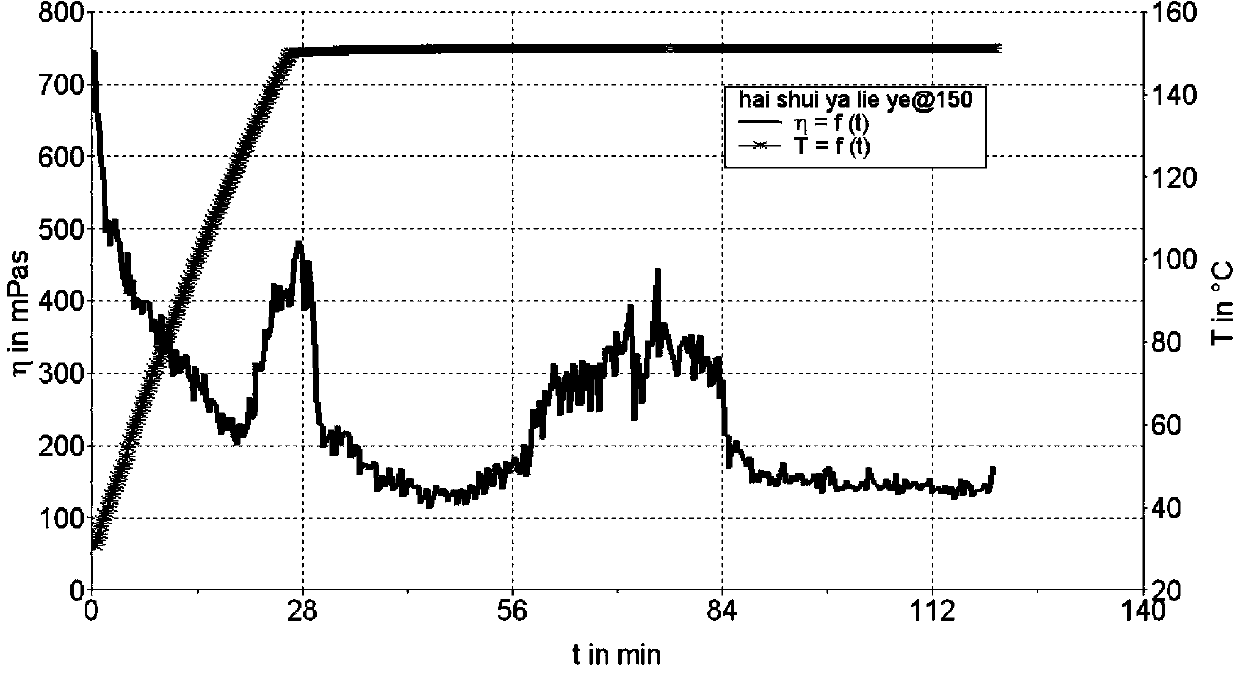

Embodiment 2

[0034] Pour 949.9 parts of seawater taken from the vicinity of BH7 well in the Binhai block of Dagang, Bohai Bay into the Wuyin mixer, start stirring, and adjust the speed (about 1000r / min); slowly add 8 parts of the thickener that has been weighed In seawater, stir for 10 minutes; add 10 parts of clay stabilizer and 12 parts of drainage aid, continue to stir for 20 minutes to make the thickener swell completely; continue to stir, add 0.1 part of gel breaker, and then slowly add 20 parts of crosslinking agent , until the vortex disappears and the liquid level rises slightly, stop stirring, and a high-temperature-resistant seawater-based fracturing fluid product will be formed.

[0035] The crosslinking agent is prepared by ferric chloride, zirconium tetrachloride, chromium chloride, formaldehyde, glycerin and water according to the mass ratio of 2:10:0.8:0.05:3:70.

[0036] The demulsification aid is made of polyoxyethylene alkyl alcohol ether nonionic surfactant, fluorocarbon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com