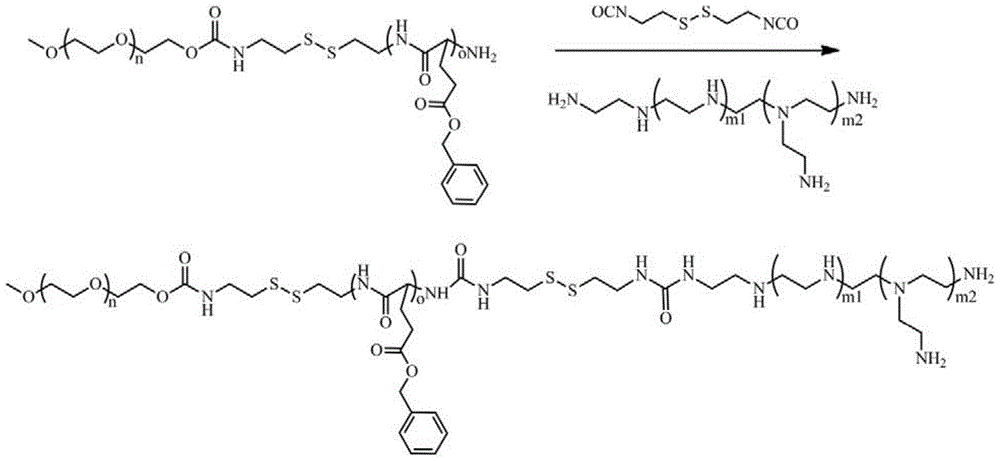

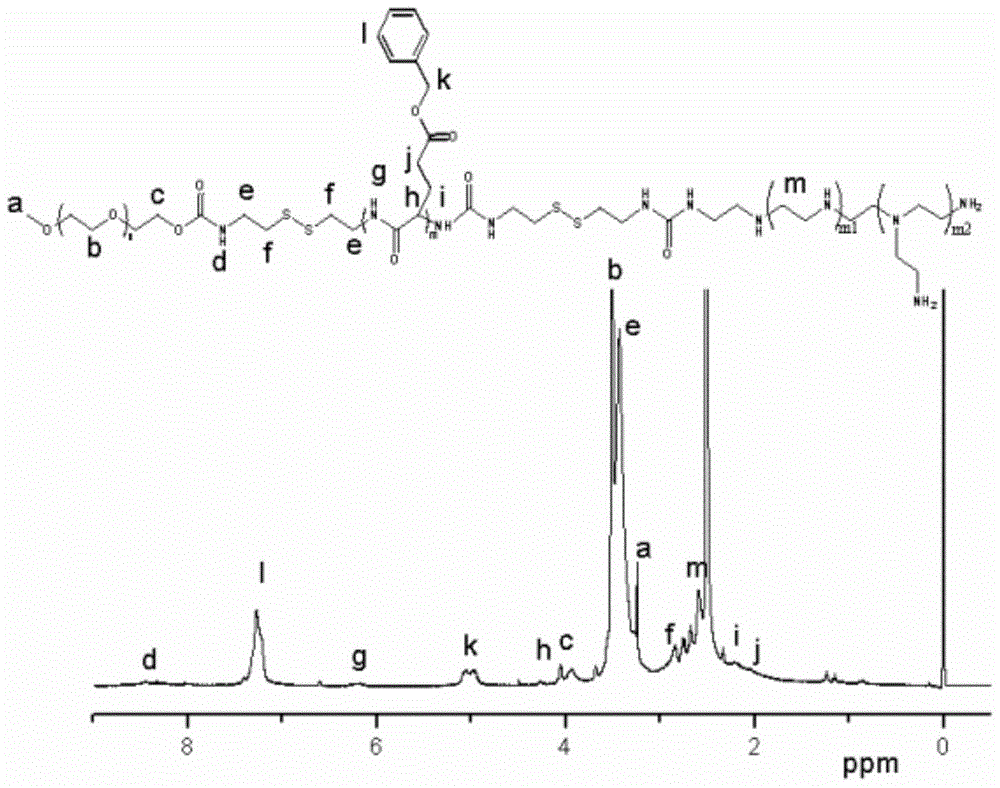

Fully dissociable polyethylene glycol-poly(l-glutamic acid-γ-benzyl ester)-polyethyleneimine copolymer and its synthesis method and application

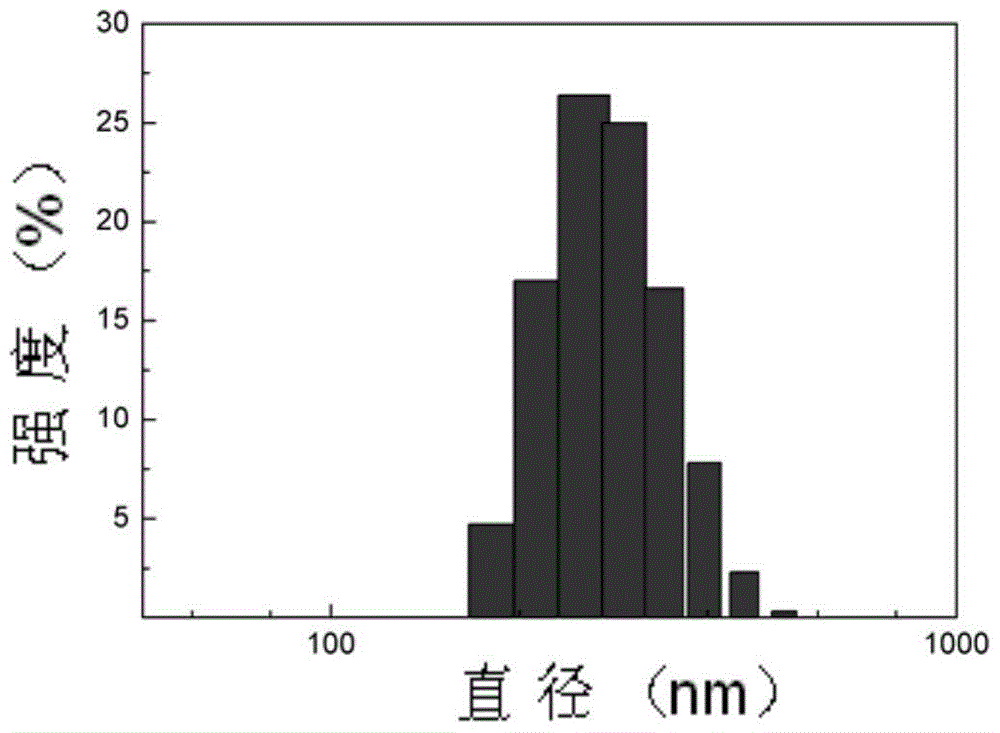

A polyethyleneimine copolymer and polyethyleneimine technology are applied in the field of completely dissociable polyethylene glycol-poly-polyethyleneimine copolymer and its synthesis, which can solve the problem of repeated medication and inability to combine , patient trouble and other problems, to achieve the effect of increasing the effective concentration of the drug, reducing the toxic and side effects, and promoting escape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] 1) Synthesis of cystaminated methoxypolyethylene glycol (mPEG):

[0047] 1.1) Dissolve dry methoxy-terminated polyethylene glycol with a molecular weight of 4000Da, dibutyltin dilaurate and 2,2'-dithiodiethylisocyanate in anhydrous toluene, and store at 85°C under a nitrogen atmosphere. After reacting for 48 hours, the resulting reaction system was precipitated three times in anhydrous n-hexane, and the precipitate was collected and dried in vacuo to obtain mPEG modified with 2,2'-dithiodiethylisocyanate; The molar ratio of polyethylene glycol, dibutyltin dilaurate and 2,2'-dithiodiethylisocyanate is 1:0.06:8; dissolve 5g of methoxy-terminated polyethylene glycol per 100ml of anhydrous toluene alcohol;

[0048] 1.2) Dissolve 2,2'-dithiodiethylisocyanate-modified mPEG in distilled water and react at 60°C for 6 hours. The reaction system is dialyzed in distilled water and freeze-dried to obtain white powder cystaminated endoform Oxypolyethylene glycol; Dissolve 5g of 2,...

Embodiment 2

[0064] 1) Synthesis of cystaminated methoxypolyethylene glycol:

[0065] 1.1) Dissolve dry methoxy-terminated polyethylene glycol with a molecular weight of 1200Da, dibutyltin dilaurate and 2,2'-dithiodiethylisocyanate in anhydrous toluene, and react at 85°C under a nitrogen atmosphere After 48 hours, the resulting reaction system was precipitated three times in anhydrous n-hexane, and the precipitate was collected and dried in vacuo to obtain 2,2'-dithiodiethylisocyanate-modified mPEG; wherein, the methoxy-terminated poly The molar ratio of ethylene glycol, dibutyltin dilaurate and 2,2'-dithiodiethylisocyanate is 1:0.04:5, and 25g of methoxy-terminated polyethylene glycol is dissolved in 100ml of anhydrous toluene ;

[0066] 1.2) Dissolve 2,2'-dithiodiethylisocyanate-modified mPEG in distilled water and react at 60°C for 6 hours. The reaction system is dialyzed in distilled water and freeze-dried to obtain white powder cystaminated endoform Oxy-polyethylene glycol; wherein,...

Embodiment 3

[0076] 1) Synthesis of cystaminated methoxypolyethylene glycol:

[0077] 1.1) Dissolve dry methoxy-terminated polyethylene glycol with a molecular weight of 2000Da, dibutyltin dilaurate and 2,2'-dithiodiethylisocyanate in anhydrous toluene, and react at 85°C under a nitrogen atmosphere After 48 hours, the resulting reaction system was precipitated three times in anhydrous n-hexane, and the precipitate was collected and dried in vacuo to obtain 2,2'-dithiodiethylisocyanate-modified mPEG; wherein, the methoxy-terminated poly The molar ratio of ethylene glycol, dibutyltin dilaurate and 2,2'-dithiodiethylisocyanate is 1:0.02:3, and 10g of methoxy-terminated polyethylene glycol is dissolved in 100ml of anhydrous toluene ;

[0078] 1.2) Dissolve 2,2'-dithiodiethylisocyanate-modified mPEG in distilled water and react at 60°C for 6 hours. The reaction system is dialyzed in distilled water and freeze-dried to obtain white powder cystaminated endoform Oxy-polyethylene glycol; wherein,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com