Preparation method of hydrophobic monomer N-alkyl acrylamide

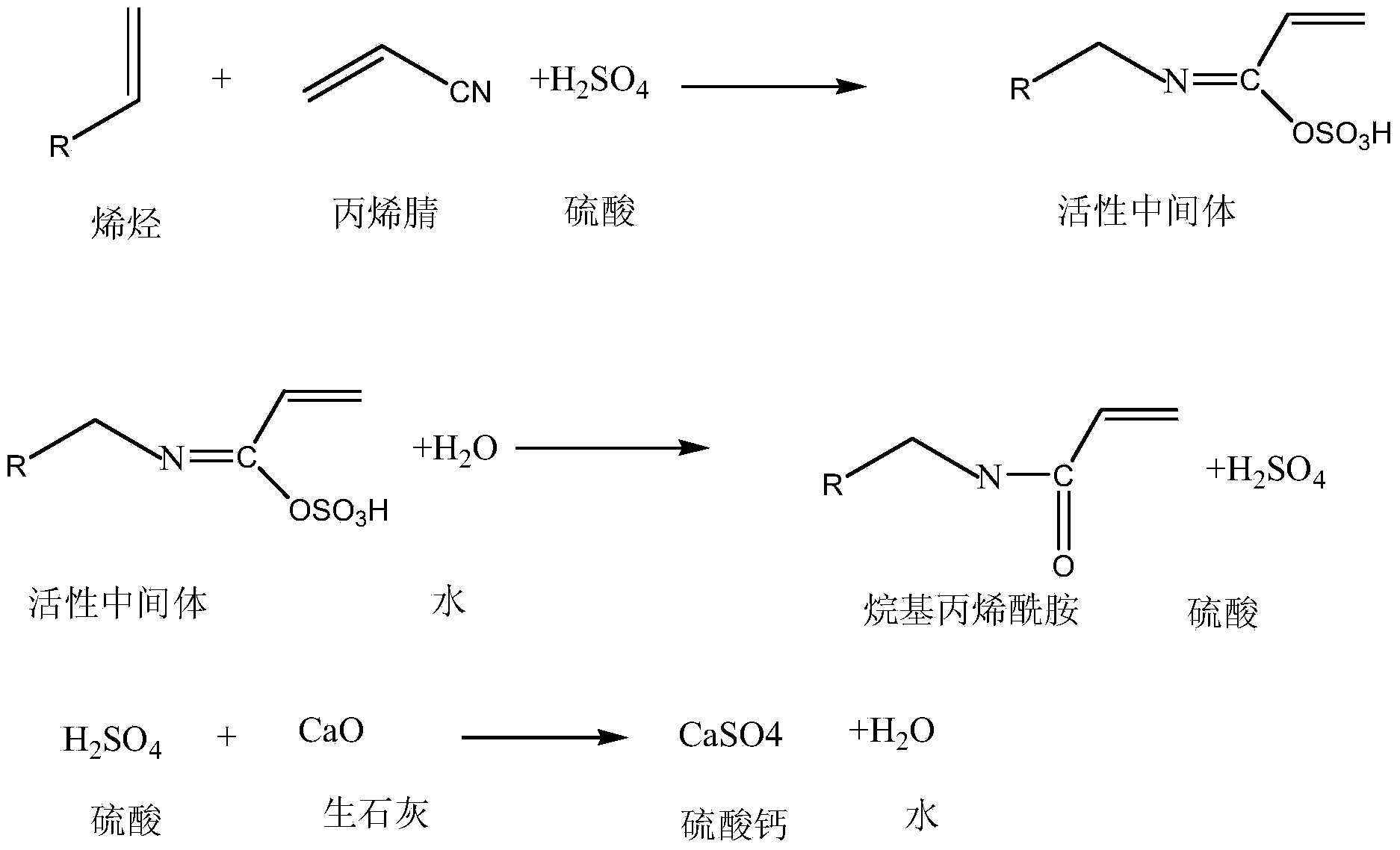

A technology of alkylacrylamide and hydrophobic monomer, which is applied in the field of preparation of hydrophobic monomer N-alkylacrylamide, can solve the problems of restricting industrial production, low product content, troublesome recycling and disposal, etc. Low cost, easy to obtain raw materials, easy to control the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Prepare a dry 1L four-neck flask equipped with a stirring paddle, feed port, thermometer and nitrogen tube, add 120 g of formic acid, 66 g (1.16 mol) of isobutylene, and 98 g (1.0 mol) of sulfuric acid into the reaction flask, and react with an ice-water bath. The mixture in the flask was cooled to 35±2°C, and 53g (1.0mol) of acrylonitrile was added dropwise; the reaction was continued to stir at 30-35°C for 4h. Add 1000g of deionized water into a 2L three-necked flask, start stirring, control the temperature at 15-20°C throughout the process, and add the above reaction solution dropwise; after the addition, continue to add about 550g of sodium hydroxide solution (15%) dropwise, and adjust the pH value to 5.0 , the white slurry was suction-filtered, and the obtained solid was washed with water until neutral. Dry in vacuum at 50°C for 4h. Obtained product 107g, the gas chromatographic examination content is 99.4%. Filtrate the mother liquor and distill to recover formi...

Embodiment 2

[0033] In the dry 1L four-necked flask that is equipped with stirring paddle, feeding port, thermometer and nitrogen tube, glacial acetic acid 160g, diisobutylene 135g (1.20mol), sulfuric acid 108g (1.1mol) are added in the reaction flask, and the reaction flask The mixture in the mixture was cooled to 30±2°C, and 53 g (1.0 mol) of acrylonitrile was added dropwise; the stirring reaction was continued at 25-30°C for 4 h. Add 1200g of deionized water into a 2L three-necked bottle, start stirring, control the temperature at 1-5°C throughout, and add the above reaction solution dropwise; after the addition, continue to add about 780g of sodium carbonate solution (15%) dropwise to adjust the pH value to 5.1, white The slurry was filtered with suction, and the obtained solid was washed with water until neutral. Dry in vacuum at 50°C for 4h. Obtain product 160g, gas chromatography inspection content is 99.1%. Filtrate the mother liquor and distill to recover acetic acid, then conce...

Embodiment 3

[0035] Prepare in the dry 1L four-neck flask that is equipped with stirring paddle, feeding port, thermometer and nitrogen tube, methanesulfonic acid 212g, hexadiene 82g (1.0mol), sulfuric acid 127.6g (1.3mol) join in the reaction flask, The mixture in the reaction flask was cooled to 5° C., and 53 g (1.0 mol) of acrylonitrile was added dropwise; the reaction was continued to stir at 15° C. for 8 h. Add 2120g of deionized water into a 2L three-necked bottle, start stirring, control the temperature at 0°C throughout the process, and add the above reaction solution dropwise; after the addition, continue to add potassium hydroxide solution dropwise to adjust the pH to 3, and filter the white slurry with suction The resulting solid was washed with water until neutral. Dry in vacuum at 50°C for 4h. Obtain product 116g, gas chromatography inspection content is 98.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com