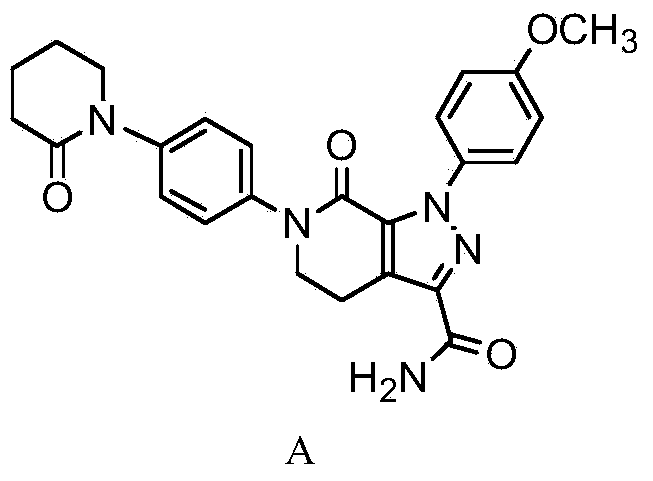

Apixaban preparation method

A technology for apixaban and a compound, which is applied in the field of preparation of apixaban, can solve the problems of high price of chemical dehydration reagents, is unsuitable for industrialized production, high moisture content requirements, etc., and achieves low production cost, low equipment requirements, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

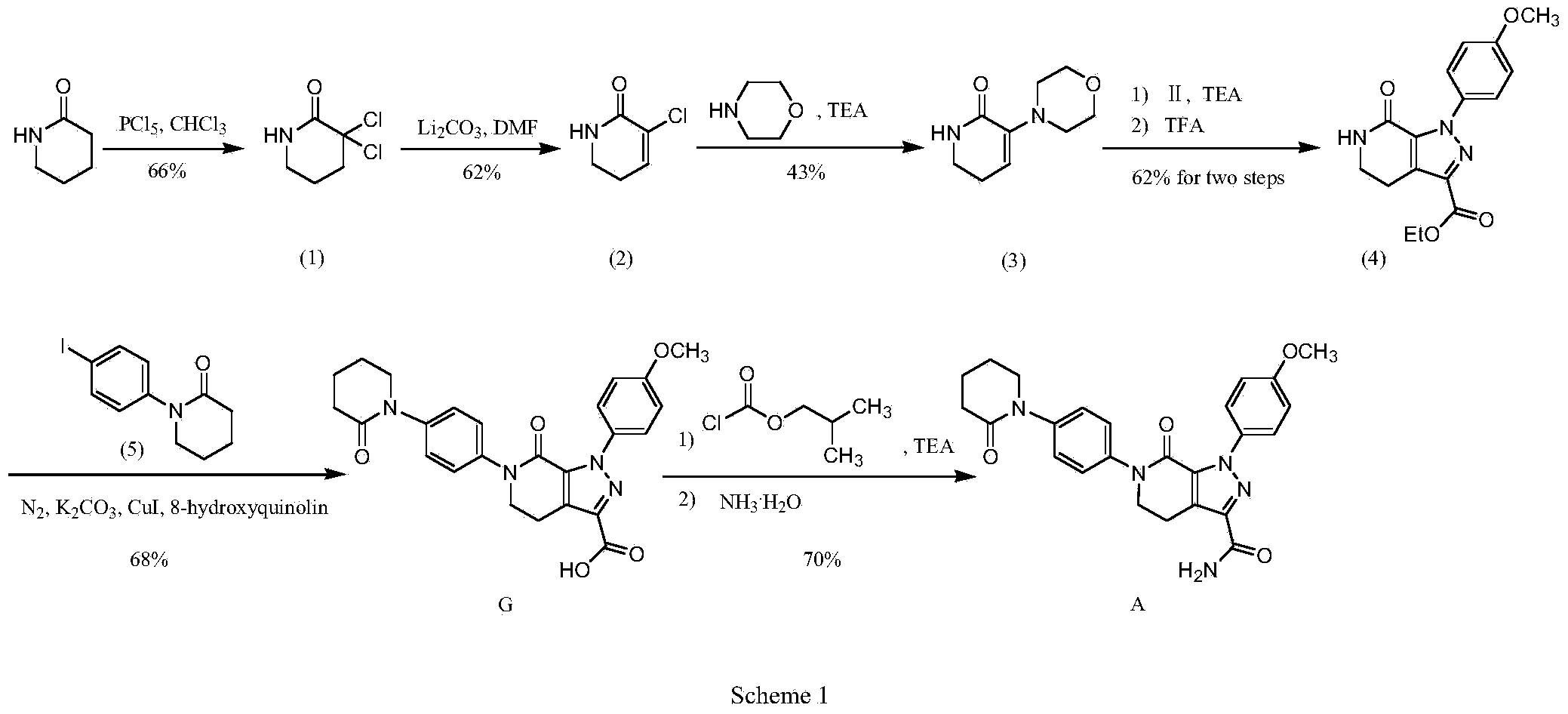

Method used

Image

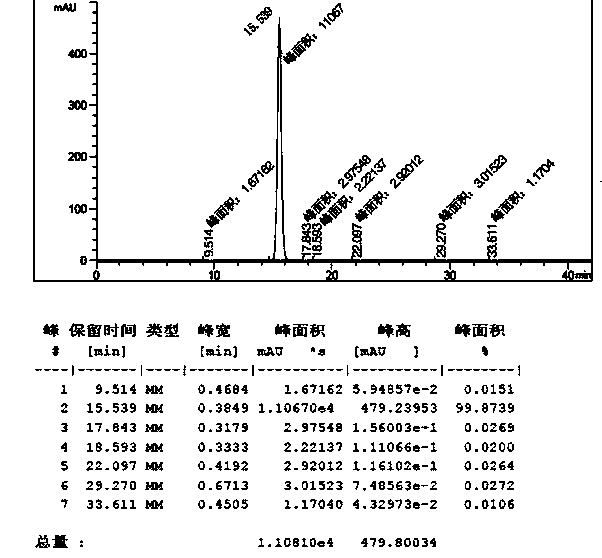

Examples

Embodiment 1

[0072] Embodiment 1: The preparation method of this apixaban adopts the following specific process steps.

[0073] (1) Synthesis of compound C:

[0074]

[0075] Add 50mL of dichloromethane into the reaction flask, and then add intermediate I (5.00g, 0.0165mol), intermediate II (5.08g, 0.0198mol), sodium carbonate (5.25g, 0.0495mol) and tetrabutyl Ammonium bromide (1.06 g, 0.0033 mol) was stirred at room temperature for 10 h, and TLC confirmed that the reaction was complete. Slowly add dilute hydrochloric acid dropwise to the reaction bottle until the pH of the system is 2-3, continue to react at room temperature for 2 hours, and then TLC confirms that the reaction is complete. Stop the reaction, add 50mL of water and stir, separate the organic layer and wash with water (2×50mL), and dry the organic layer with anhydrous sodium sulfate. Suction filtration, the filtrate was evaporated under reduced pressure to remove the solvent to obtain a yellow solid, which was recrystal...

Embodiment 2

[0091] Embodiment 2: The preparation method of this apixaban adopts the following specific process steps.

[0092] (1) Synthesis of Compound C:

[0093] Add 50mL of dichloromethane into the reaction flask, and add intermediate I (5.00g, 0.0165mol), intermediate II (4.67g, 0.0182mol), potassium carbonate (6.83g, 0.0495mol) and tetrabutyl Ammonium bromide (1.06 g, 0.0033 mol) was stirred and reacted at a temperature of 20° C. for 10 h, and TLC confirmed that the reaction was complete. The temperature was lowered in an ice-water bath, and dilute hydrochloric acid was slowly added dropwise to the reaction flask at 0°C until the pH of the system was about 2-3. After 3 hours of reaction under temperature control, TLC confirmed that the reaction was complete. Stop the reaction, add 50mL of water and stir, separate the organic layer and wash with water (2×50mL), and dry the organic layer with anhydrous sodium sulfate. After suction filtration, the filtrate was evaporated under reduc...

Embodiment 3

[0104] Embodiment 3: The preparation method of this apixaban adopts the following specific process steps.

[0105] (1) Synthesis of compound C:

[0106] Add 50mL of ethyl acetate to the reaction flask, and then add intermediate I (5.00g, 0.0165mol), intermediate II (4.66g, 0.0182mol), triethylamine (4.33g, 0.0413) and tetrabutyl Ammonium bromide (0.80 g, 0.0025 mol) was heated to 70° C. for 5 h, and TLC confirmed that the reaction was complete. After cooling down to room temperature, dilute sulfuric acid was slowly added dropwise to the reaction flask until the pH of the system was about 2-3, and the reaction was continued at 70°C for 0.5h, and TLC confirmed that the reaction was complete. Stop the reaction, add 50mL of water and stir, separate the organic layer and wash with water (2×50mL), and dry the organic layer with anhydrous sodium sulfate. After suction filtration, the filtrate was evaporated under reduced pressure to remove the solvent to obtain a yellow solid, whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com