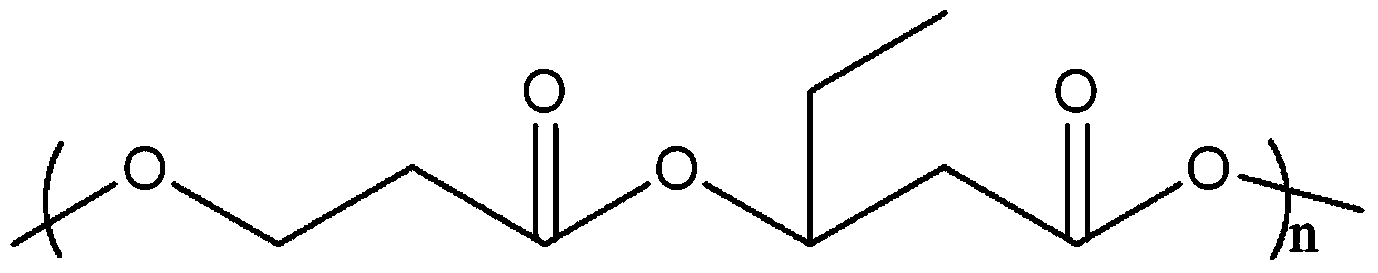

Poly-3-hydroxy propionic acid copolymer and production method thereof

A polyhydroxy fatty acid and gene technology, applied in the field of genetic engineering, can solve problems such as low melting point and opacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

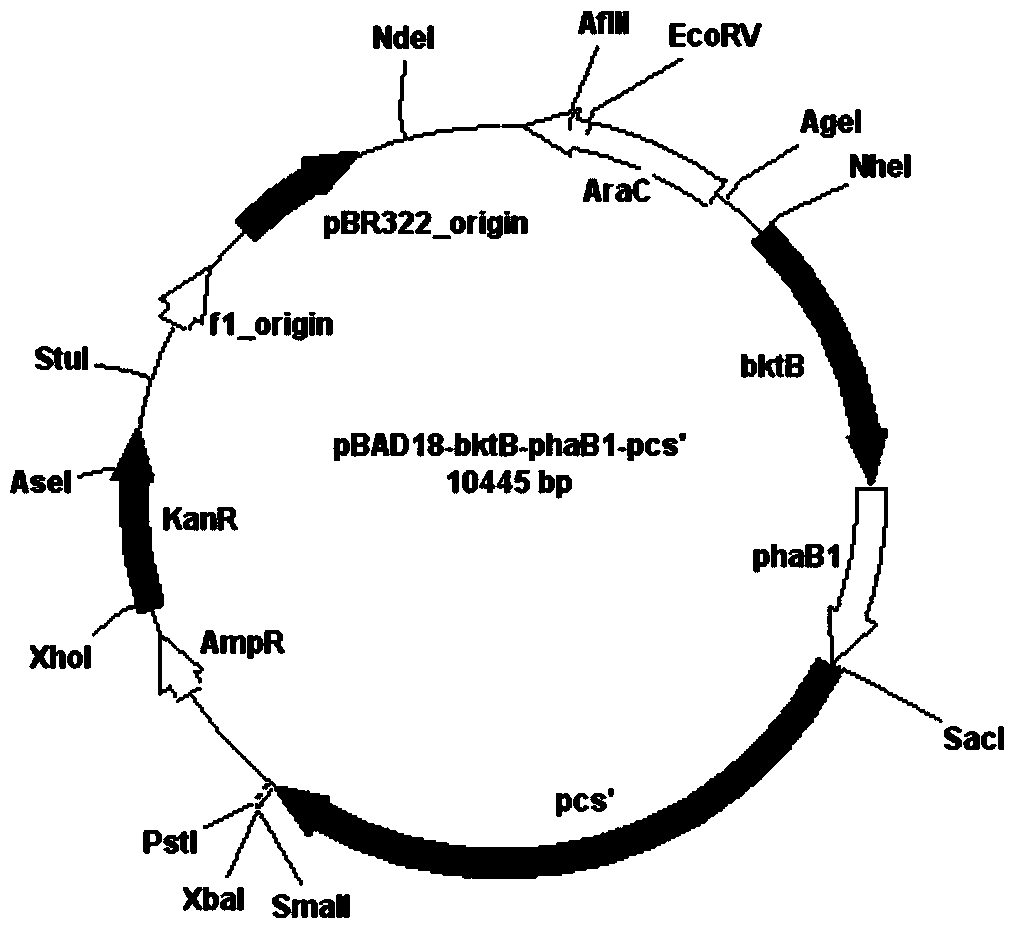

[0042] Example 1 Construction of Genetically Engineered Bacteria

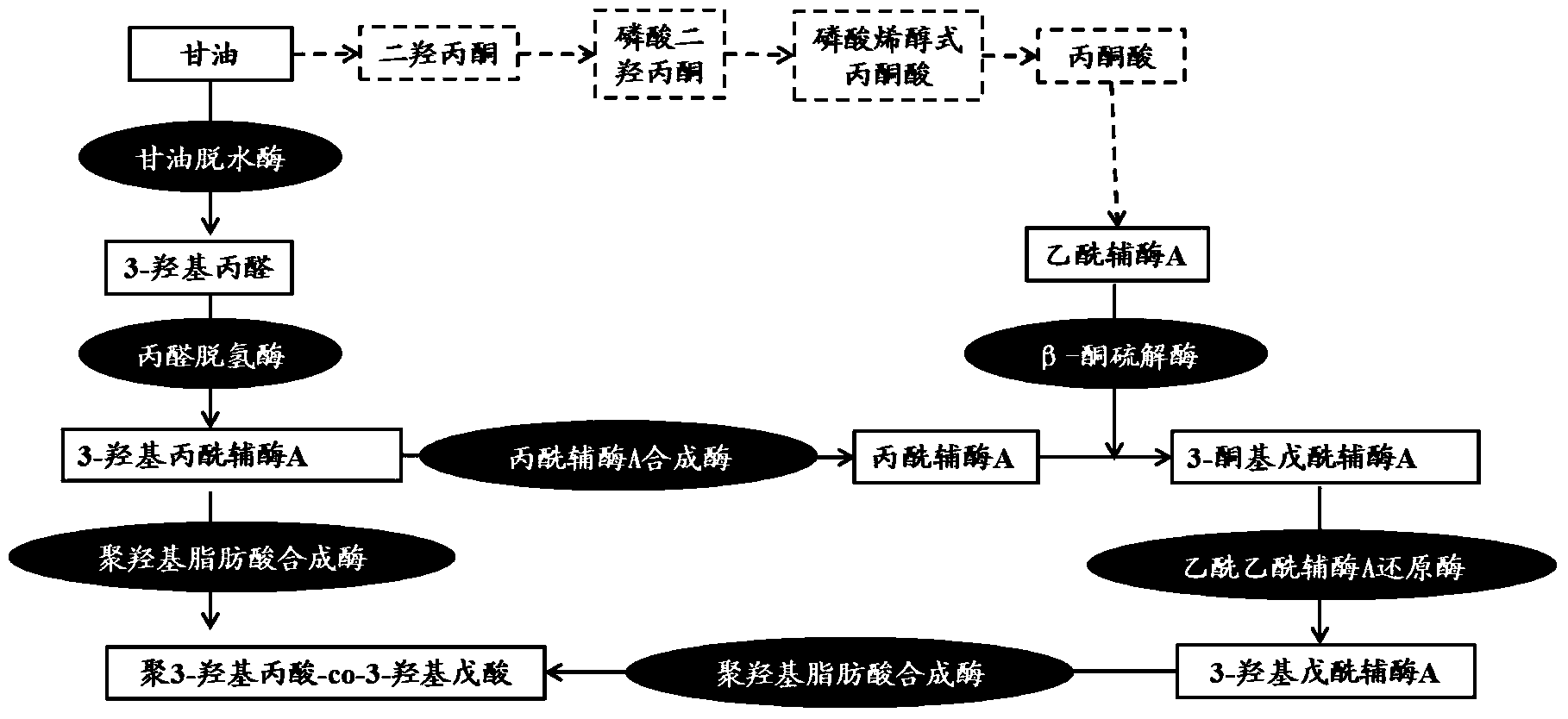

[0043] By integrating the glycerol dehydratase gene (dhaB123) (dhaB1Gene ID: 7947197; dhaB2Gene ID: 7947198; dhaB3Gene ID: 7947200), glycerol dehydratase reactivating enzyme gene (gdrAB) (gdrA Gene ID: 6936977; gdrB Gene ID: 6938011 ) Escherichia coli overexpressed propionaldehyde dehydrogenase gene (pduP, Gene ID: 1253572), polyhydroxy fatty acid synthase gene (phaC, Gene ID: 4250156), β-ketoacyl-CoA thiolase gene (bktB , Gene ID: 4248815), acetoacetyl-CoA reductase gene (phaB 1 , Gene ID: 4249784), the propionyl-CoA synthetase gene (pcs') realizes the synthesis of P(3HP-co-3HV) with glycerol as the carbon source, and the synthesis of poly 3-hydroxypropionate-co-3-hydroxypentane by glycerol Acid metabolic pathways such as figure 2 shown.

[0044] 1. Gene integration

[0045] After the genes dhaB and gdrAB are cloned, the dhaB and gdrAB are integrated into the Escherichia coli genome through gene integrati...

Embodiment 2

[0065] Example 2 Production of P(3HP-co-3HV) by fermentation

[0066] The production of P(3HP-co-3HV) was investigated by adjusting the amount of inducer and the use of organic nitrogen source.

[0067] 2.1) 0.5mM IPTG and 0.02% arabinose induced

[0068] Change the nitrogen source of the M9 medium to 5g / L yeast powder, peptone or beef extract, inoculate activated Escherichia coli at a ratio of 1:100, when the OD 600 When the range of 0.6-0.8 was reached, the inducer IPTG and arabinose were added to the final concentrations of 0.5mM and 0.02%, respectively, and P(3HP-co-3HV) was extracted after continuing to culture for 48h.

[0069] When the nitrogen source was beef extract, P(3HP-co-3HV) accounted for 12.94% (w / w) of dry cell weight, and the yield was 0.45g / L, which was the highest. The yield was the lowest when the nitrogen source was peptone, P(3HP-co-3HV) accounted for 6.53% of the dry cell weight, and the yield was 0.24g / L. When the nitrogen source was yeast powder, P...

Embodiment 3

[0074] The P(3HP-co-3HV) and poly-3-hydroxypropionic acid samples obtained in the present invention are washed with ethanol and dried in vacuum, and the melting point and crystallinity are measured by differential scanning calorimetry, and the temperature setting range is -80°C to 200°C. °C, the nitrogen flow rate is 50ml / min. The melting point of P(3HP-co-3HV) increased from 76°C of poly-3-hydroxypropionic acid to 147°C, and the crystallinity decreased from 74% of poly-3-hydroxypropionic acid to 35%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com