A kind of foaming fluorine-containing polyimide and preparation method thereof

A technology of fluorine-containing polyimide and polyimide, which is applied in the field of foamed polyimide and its foam preparation, can solve the problem of poor cell uniformity and process stability, and reduce the flame retardancy of polyimide foam problems such as foam opening rate, pore size increase, etc., to achieve the effects of regular microscopic pore structure, light wave transmission characteristics, high foaming and curing activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

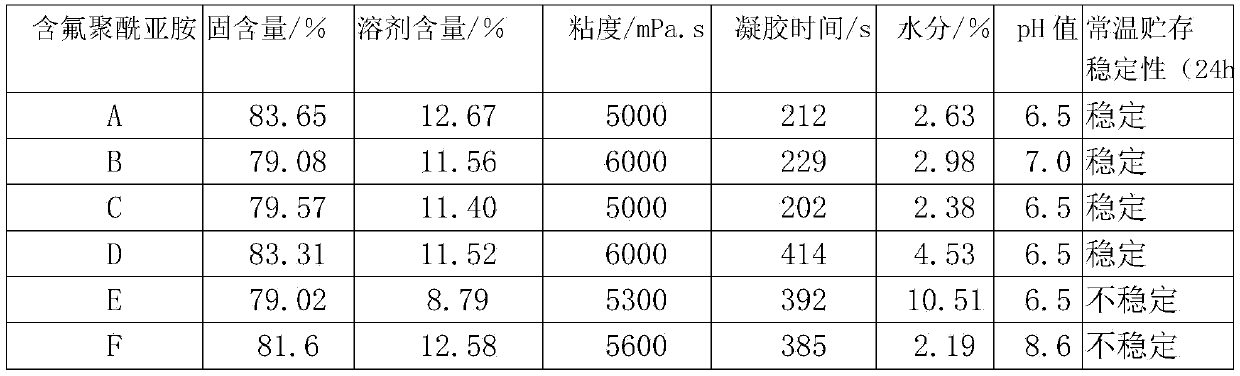

[0029] Add 2,2'-bis(3-amino-4-hydroxybenzene) dissolved in N,N'-dimethylformamide (DMF) into a three-neck flask equipped with mechanical stirring, a thermometer, and a reflux condenser in sequence according to the proportion Base) 36.6g (0.1mol) of hexafluoropropane, 44.4g (0.1mol) of 4,4'-(hexafluoroisopropyl) diphthalic dianhydride and 5-norbornene-2,3 -Dicarboxylic acid anhydride 1.6g (0.01mol), the cooling liquid is circulated under stirring to maintain the condensation reaction at 10°C, the total condensation reaction takes about 5 hours; the system is heated to 20°C, and the organic base 1,8-diazepine is added Bicyclo[5.4.0]undec-7-ene (DBU) was neutralized to a pH value of 6.5; the solution system was dehydrated at a vacuum of 0.080MPa and a water bath at 60°C to a viscosity of 5000mPa.s to stop dehydration, and cooled to Discharge at 50°C to obtain fluorine-containing polyimide A, whose performance indicators are listed in Table 1.

[0030]100 parts by weight of fluor...

Embodiment 2

[0032] Add 3,3'-diamino-5,5'-bis( Trifluoromethyl)biphenyl 32.0g (0.1mol), 1,4-bis(trifluoromethyl)-2,3,5,6-benzenetetracarboxylic dianhydride 46.5g (0.1mol) and end-capping agent 1.6g (0.01mol) of 5-norbornene-2,3-dicarboxylic acid anhydride, the cooling liquid was circulated under stirring to maintain the condensation reaction at 10°C, and the total condensation reaction took about 8 hours; the system was heated to 20°C, and added The organic base 1,5-diazabicyclo[5.4.0]undec-5-ene (DBN) was neutralized to pH 7.0; the resin system was dehydrated to viscosity under reduced pressure in a water bath with a vacuum degree of 0.082MPa and 50°C Stop dehydration at 6000mPa.s, cool down to 50°C and discharge to obtain fluorine-containing polyimide B, and its performance indicators are listed in Table 1.

[0033] 100 parts by weight of fluorine-containing polyimide B was quickly foamed under 700W microwave conditions for 10 minutes, and left at room temperature for post-curing to pre...

Embodiment 3

[0035] Add 2,2'-bis(3-amino-4-hydroxybenzene) dissolved in N,N'-dimethylformamide (DMF) into a three-neck flask equipped with mechanical stirring, a thermometer, and a reflux condenser in sequence according to the proportion Base) 36.6g (0.1mol) of hexafluoropropane, 42.7g (0.1mol) of 1,4-difluoropyromellitic dianhydride and 1.6g ( 0.01mol), the cooling liquid is circulated under stirring to maintain the condensation reaction at 10°C, the total condensation reaction time is about 6.5 hours; the system is heated to 20°C, and the organic base 1,8-diazabicyclo[5.4.0] is added Undec-7-ene (DBU) was neutralized to a pH value of 6.5; the resin system was dehydrated under reduced pressure in a water bath with a vacuum degree of 0.081MPa and 60°C to a viscosity of 5800mPa. Fluoropolyimide C, its performance indicators are listed in Table 1.

[0036] 100 parts by weight of fluorine-containing polyimide C was rapidly foamed under 700W microwave conditions for 10 minutes, and left at ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com