Carbon-based desulfurization catalyst for low temperature catalytic oxidation of sulfur dioxide and its preparation and application

A desulfurization catalyst, sulfur dioxide technology, applied in physical/chemical process catalysts, catalyst carriers, inorganic chemistry, etc., can solve the problem of low operating space velocity, large amount of desulfurization agent and equipment area, complex desulfurization-regeneration-desulfurization control, etc. problem, to achieve the effect of improving desulfurization efficiency and superior performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

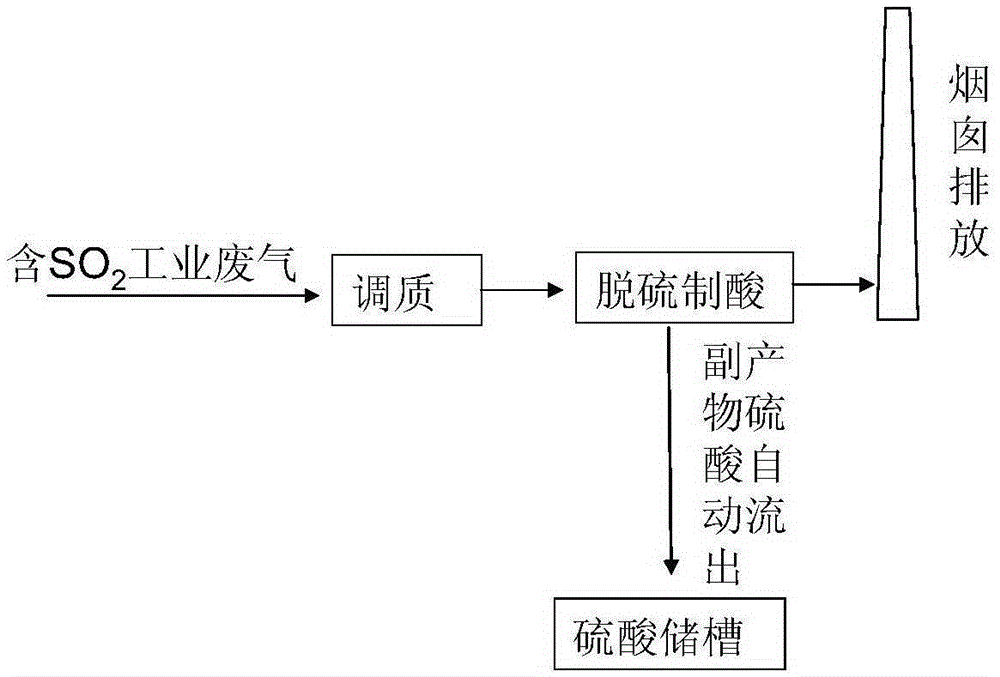

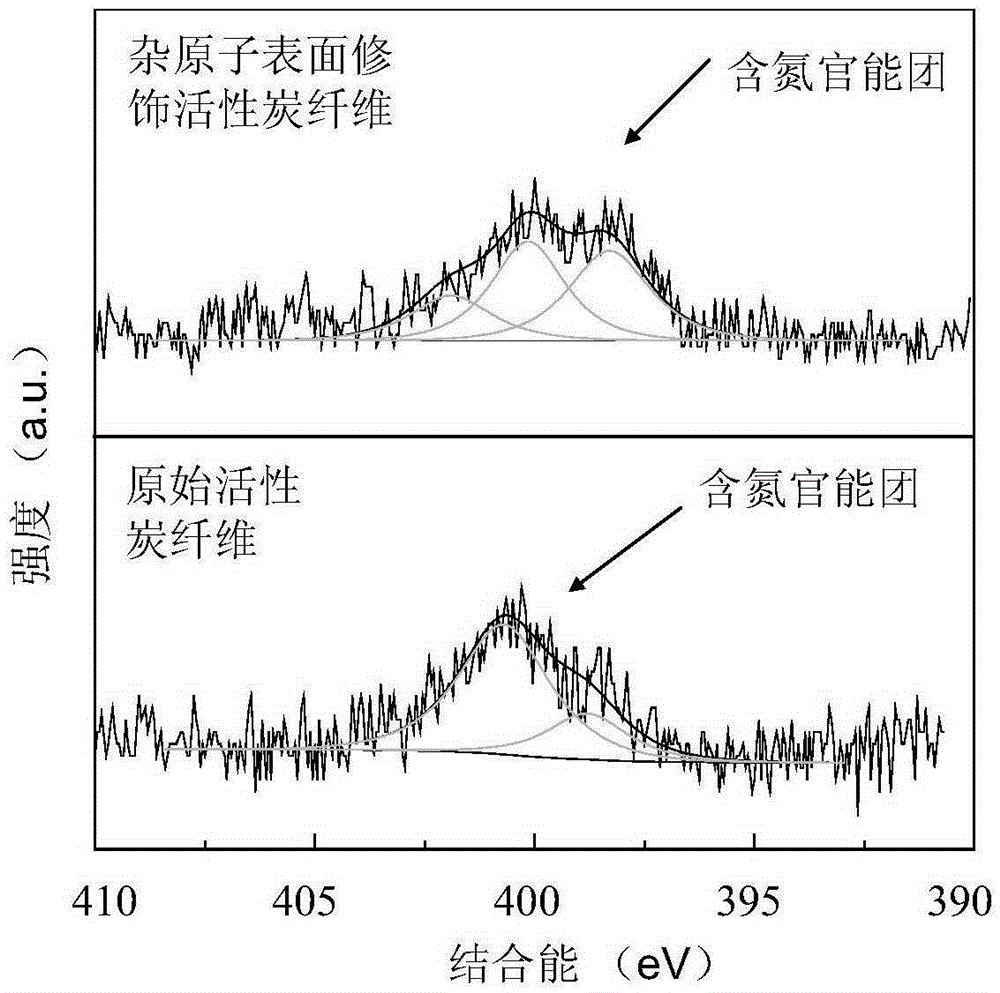

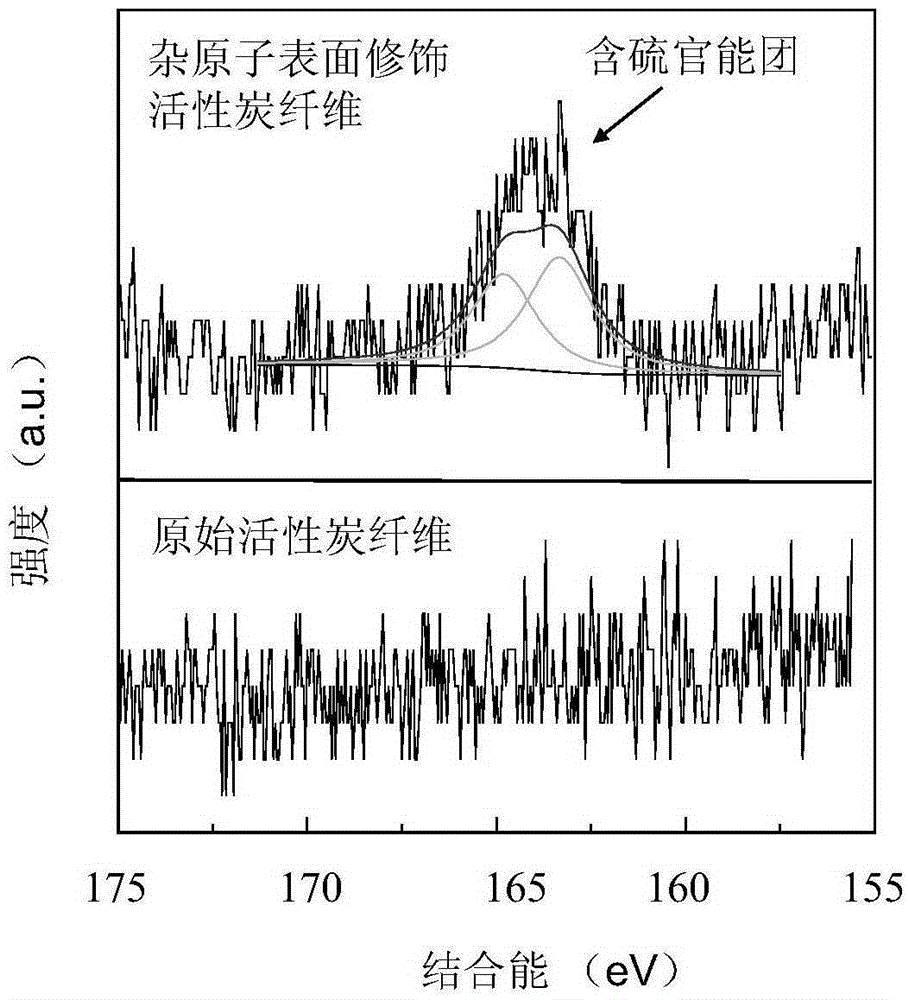

Embodiment 1

[0039] The activated carbon fiber is soaked in a nitric acid solution with a mass concentration of 30%, and the surface is oxidized for about 2 hours by soaking in a constant temperature water bath at 60°C. The reacted activated carbon fibers were rinsed with deionized water to about pH 6, and then dried in an oven at about 105°C overnight. 100 grams of thiourea were dissolved in an 80% ethanol aqueous solution to prepare a 1.0 mol / L thiourea solution. Pour 100 grams of acid-washed activated carbon fibers into the above thiourea solution, mix well, slowly evaporate ethanol and water at about 60°C, and then dry in an oven at about 105°C overnight. The activated carbon fiber loaded with thiourea was placed in a muffle furnace, and under nitrogen protection, the temperature was raised from room temperature to about 900 °C at a heating rate of 5 °C / min, and kept at this temperature for about 0.5 hours, and cooled. Then the activated carbon fiber desulfurization catalyst with nitr...

Embodiment 2

[0043] The activated carbon fiber is soaked in a phosphoric acid solution with a mass concentration of 30%, and the surface is oxidized by soaking in a constant temperature water bath at a temperature of 60°C for about 2 hours. The reacted activated carbon fibers were rinsed with deionized water to a pH of about 7.2, and then dried in an oven at about 105°C overnight. Dissolve 100 g of thiourea in water to prepare a 3.0 mol / L thiourea solution. Pour 10 grams of acid-washed activated carbon fibers into the above thiourea solution, mix well, slowly evaporate the water at about 60°C, and then dry in an oven at about 105°C overnight. The activated carbon fiber loaded with thiourea was placed in a muffle furnace, and under nitrogen protection, the temperature was raised from room temperature to about 600 °C at a heating rate of 1 °C / min, and kept at this temperature for about 3 hours, and cooled. Then the activated carbon fiber desulfurization catalyst with nitrogen and sulfur het...

Embodiment 3

[0045] The activated carbon fibers were placed in a muffle furnace, and air with a flow rate of 300ml / min was introduced, and the temperature was raised from room temperature to about 300°C at a heating rate of 5°C / min, and maintained at this temperature for about 2 hours. Dissolve 10 grams of ammonium thiocyanate in water to prepare a 2.0 mol / L ammonium thiocyanate solution. Pour 100 grams of surface pre-oxidized activated carbon fibers into the above ammonium cyanide solution, mix well, slowly evaporate the water at about 60°C, and then dry in an oven at about 105°C overnight. The activated carbon fiber loaded with ammonium thiocyanate was placed in a muffle furnace, and under nitrogen protection, the temperature was raised from room temperature to about 800 °C at a heating rate of 20 °C / min, and kept at this temperature for about 2 hours. , and after cooling, an activated carbon fiber desulfurization catalyst with nitrogen and sulfur heteroatoms surface-modified with ammoni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com