Preparation method and application of multifunctional material for water treatment

A multi-functional, water treatment technology, applied in biological water/sewage treatment, adsorbed water/sewage treatment, water/sludge/sewage treatment, etc. It can solve the problem of co-treatment of sludge without iron oxide, increase cost, and reduce hydroxyl free radicals. It can achieve the effect of resource utilization, convenient operation and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

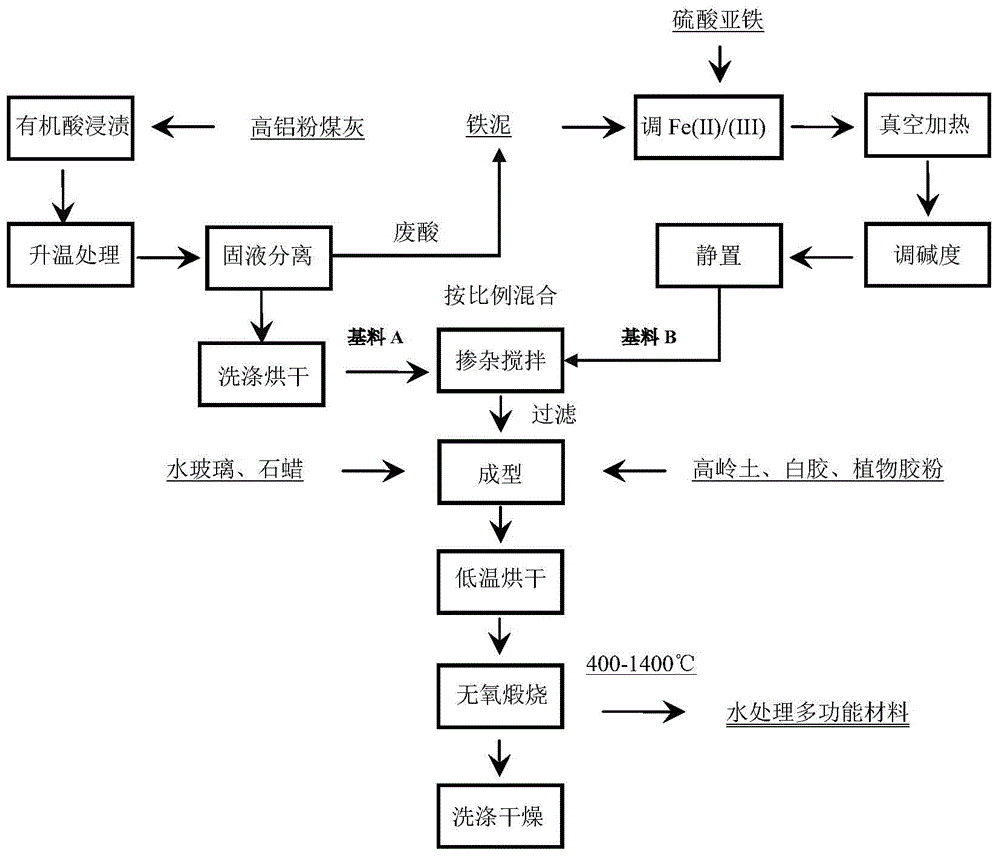

Embodiment 1

[0022] Immerse the high-alumina fly ash with organic acid such as oxalic acid for 2 hours, the concentration of oxalic acid is 3%, and continuously add to control the pH below 1 for 3 hours; after stopping the acid addition, the temperature rises to 90°C, and maintains the pH at about 5 for 2 hours, and Basically unchanged, it is dried after filtration and used as base material A for later use. Use the above waste acid, iron mud and ferrous sulfate to prepare iron mud with a molar ratio of 1:2.2 in the supernatant Fe(II) / Fe(III), adjust the vacuum degree and alkalinity, and obtain black iron oxide powder as a base material b.

[0023] Weigh 100g of base material A and add the above base material B and stir for 5 hours. The mass of black iron oxide accounts for about 10% of the total mass, and then filter, wash and dry the above mixed material. Its preparation process is as follows: take 100 parts of dried base material A and base material B with a solid content of about 10 g,...

Embodiment 2

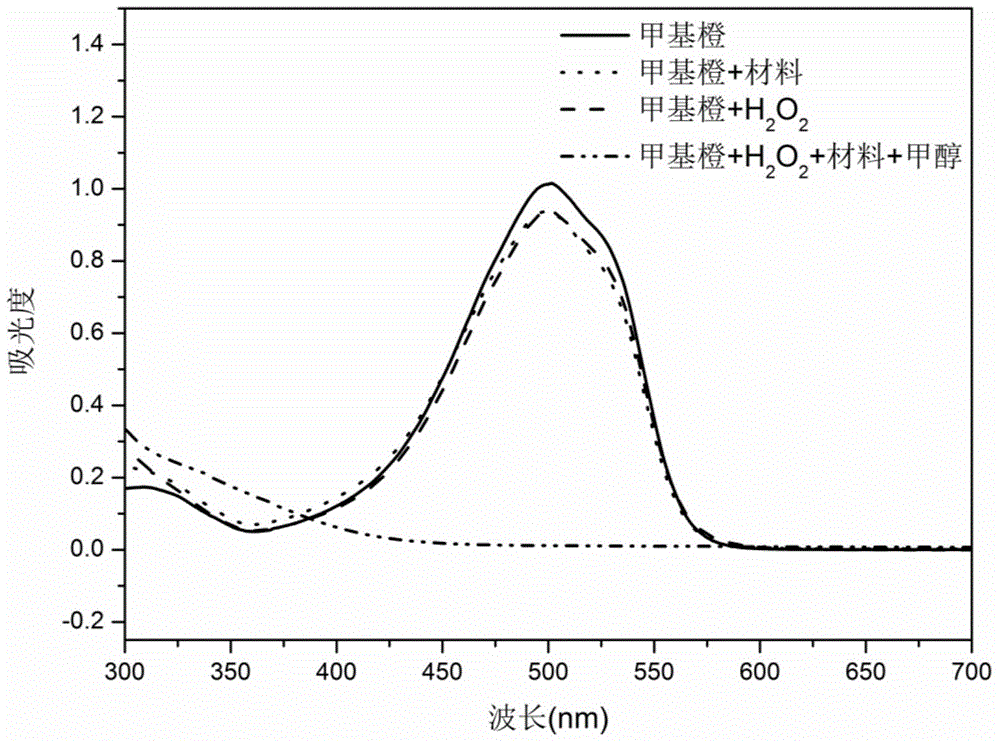

[0029] Iron mud and ferrous sulfate were used to prepare black iron mud with a supernatant Fe(II) / Fe(III) molar ratio of 1:2. The preparation steps of the following water treatment materials are the same as above. Weigh 5g of the above water treatment material and add it to a methyl orange aqueous solution with a concentration of 10mg / L and a volume of 50ml, add 150mg / L of 30-40% H 2 o 2 Aqueous solution, adjust pH to 3, Fenton-like reaction oxidative degradation for 2h. The UV-Vis spectrum curve of Fenton-like oxidation degradation of methyl orange is shown in the figure.

Embodiment 3

[0031] Use iron mud and ferrous sulfate to prepare black iron mud with a molar ratio of 1:2.5 of the supernatant Fe(II) / Fe(III), and common fly ash 400 mesh, add alumina powder (200 mesh) to prepare High alumina fly ash containing more than 45% alumina.

[0032] Weigh 100 parts of high-alumina fly ash and add it to a black iron slurry solution with a solid content of about 7g, stir and mix for 5 hours, then filter, wash and dry. Its preparation process is as follows: weigh 100 parts of dry mixture, grind evenly, then add 10 parts of kaolin, 28 parts of water glass (30-40%) and 1.5 parts of liquid paraffin, 2 parts of white glue, 3 parts of vegetable rubber powder, and stir well until uniform, mixed into balls, dried the obtained water treatment material at 120°C for 2 hours, and then anaerobically calcined at 500°C for 3 hours to obtain the water treatment material.

[0033] The chemical composition of ordinary fly ash is shown in the table below.

[0034] Analysis results o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com