A novel vanadium phosphate photocatalytic material and its preparation method and application

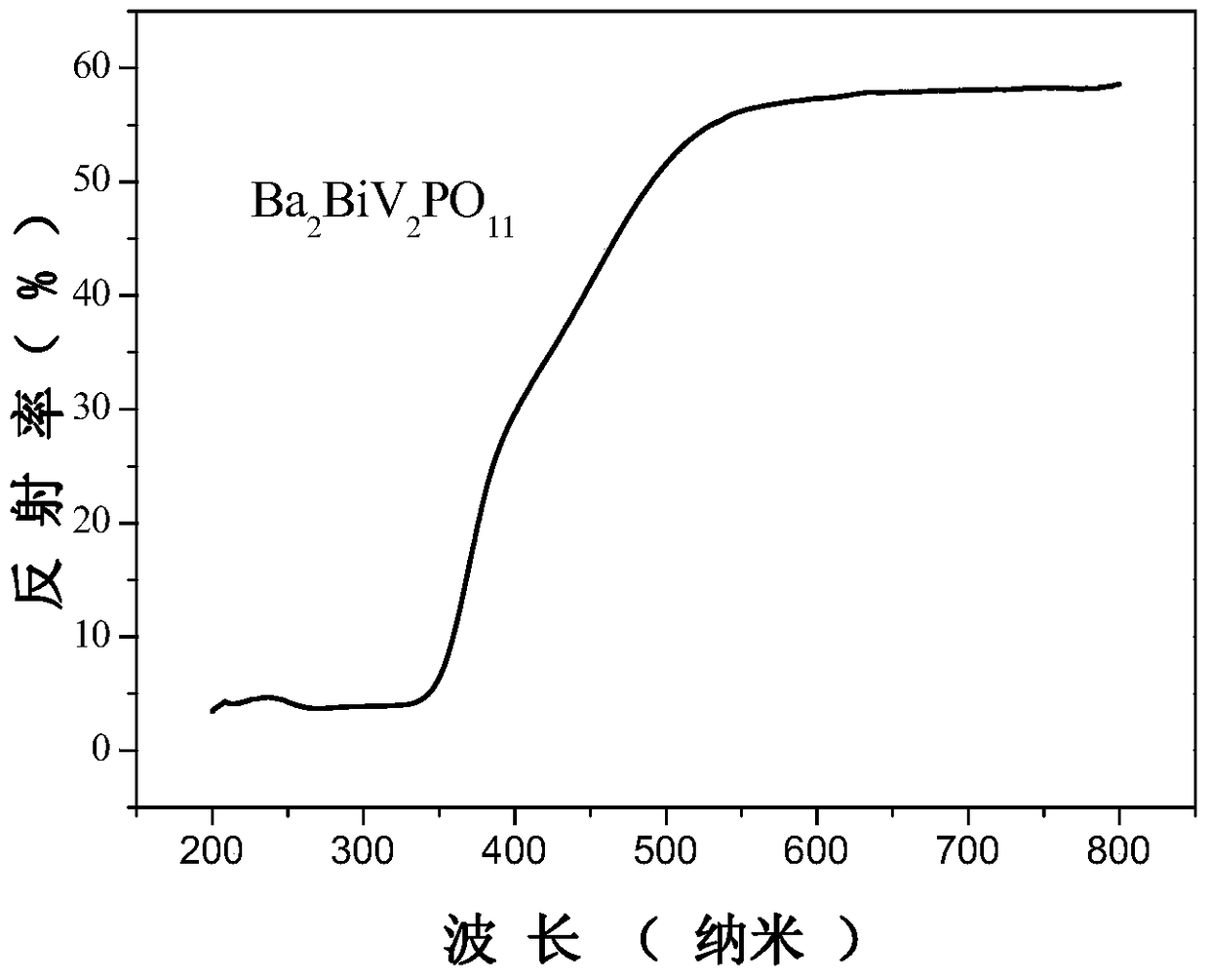

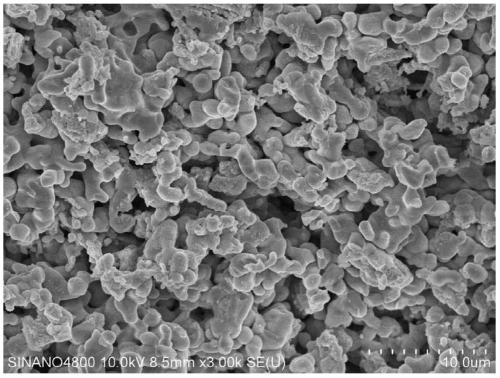

A photocatalytic material, vanadium phosphate technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problem of low catalytic efficiency of vanadate photocatalysts, uneven particle size distribution, High equipment requirements, to achieve good photocatalytic activity, stable photocatalytic degradation performance, and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

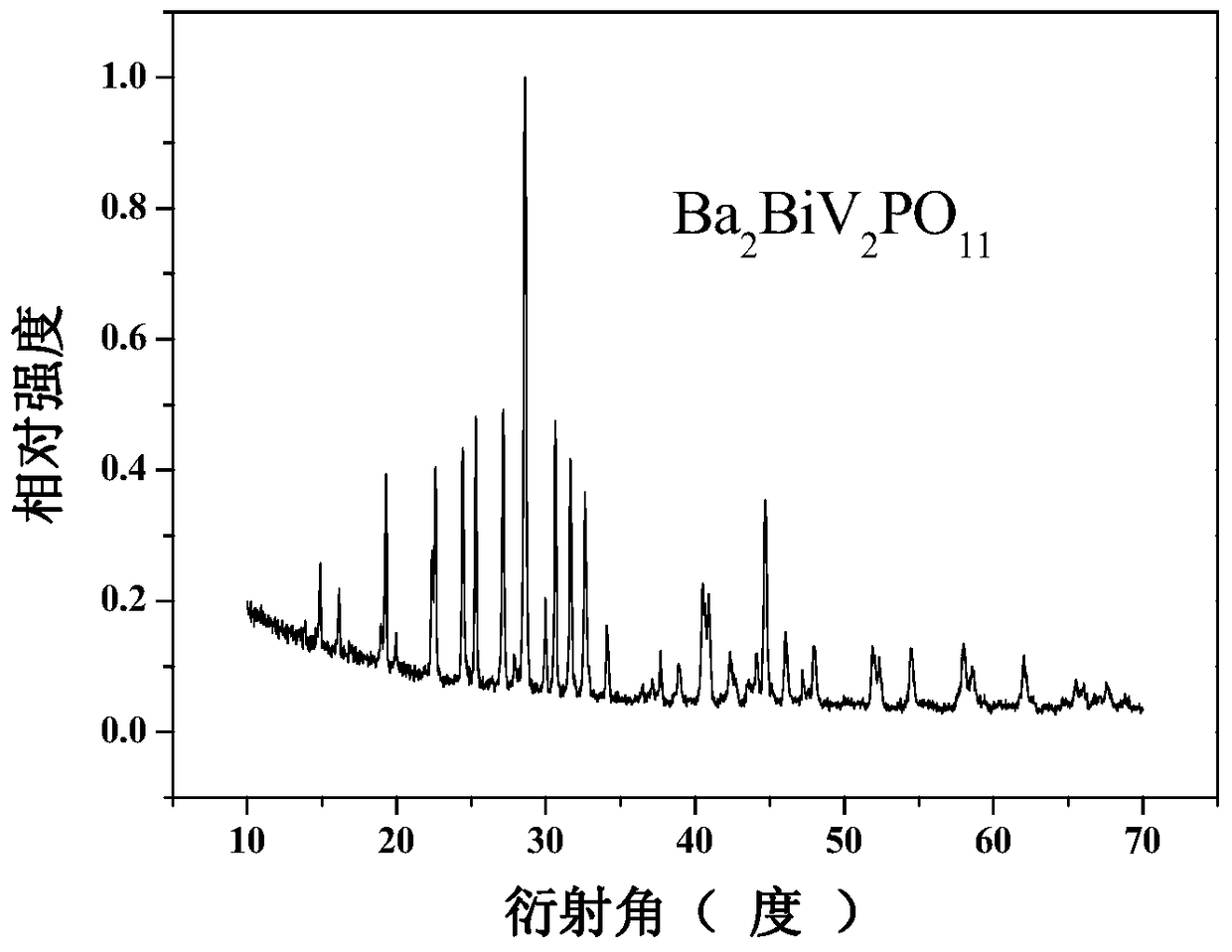

[0038] Preparation of Vanadium Phosphate Ba by Solid Phase Synthesis 2 BiV 2 PO 11 Photocatalytic materials and their applications

[0039] The steps are as follows:

[0040] (1) According to the chemical formula Ba 2 BiV 2 PO 11 The stoichiometric ratio of each element in the formula is weighed separately from barium carbonate BaCO 3 : 1.973 g, bismuth oxide Bi 2 o 3 : 1.165 g, vanadium pentoxide V 2 o 5 : 0.910 g, ammonium dihydrogen phosphate NH 4 h 2 PO 4 : 0.575 grams, ground in an agate mortar and mixed well;

[0041] (2) Take the mixture of the above step (1), select the air atmosphere for pre-calcination, the calcination temperature is 350 ° C, the calcination time is 10 hours, then cool to room temperature, and take out the sample;

[0042] (3) Fully mix and grind the pre-calcined raw materials again, carry out the second calcination in the air atmosphere, the calcination temperature is 750°C, and the calcination time is 7 hours, then automatically lower...

Embodiment 2

[0050] Preparation of Vanadium Phosphate Ba by Solid Phase Synthesis 2 BiV 2 PO 11 Photocatalytic materials and their applications

[0051] The steps are as follows:

[0052] (1) According to the chemical formula Ba 2 BiV 2 PO 11 The stoichiometric ratio of each element in the formula, weighed barium oxide BaO: 1.533 grams, bismuth subcarbonate (BiO) 2 CO 3 0.5H 2 O: 1.298 g, ammonium metavanadate NH 4 VO 3 : 1.170 g, phosphorus pentoxide P 2 o 5 : 0.355 grams, ground in an agate mortar and mixed well;

[0053] (2) Take the mixture of the above step (1), select the air atmosphere for pre-calcination, the calcination temperature is 500 ° C, the calcination time is 5 hours, then cool to room temperature, and take out the sample;

[0054] (3) Fully mix and grind the pre-calcined raw materials again, carry out the second calcination in the air atmosphere, the calcination temperature is 550°C, the calcination time is 12 hours, then cool to room temperature, take out th...

Embodiment 3

[0058] Preparation of Vanadium Phosphate Ba by Solid Phase Synthesis 2 BiV 2 PO 11 Photocatalytic materials and their applications

[0059] The steps are as follows:

[0060] (1) According to the chemical formula Ba 2 BiV 2 PO 11 The stoichiometric ratio of each element in the formula is weighed separately from barium carbonate BaCO 3 : 1.973 g, bismuth subcarbonate (BiO) 2 CO 3 0.5H 2 O: 1.298 g, ammonium metavanadate NH 4 VO 3 : 1.170 g, monoammonium phosphate NH 4 h 2 PO 4 : 0.575 grams, ground and mixed in an agate mortar;

[0061] (2) Take the mixture of the above step (1), select the air atmosphere for pre-calcination, the pre-calcination temperature is 450 ° C, the calcination time is 8 hours, then cool to room temperature, and take out the sample;

[0062] (3) Fully mix and grind the pre-calcined raw materials again, and perform a second calcination in an air atmosphere at a calcination temperature of 700°C for 9 hours, then cool to room temperature, tak...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| band gap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com