Preparation method of lithium air battery electrode

A lithium-air battery and electrode technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of reducing battery energy density and increasing positive electrode impedance, and achieve the effect of improving energy density, improving conductivity and good effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

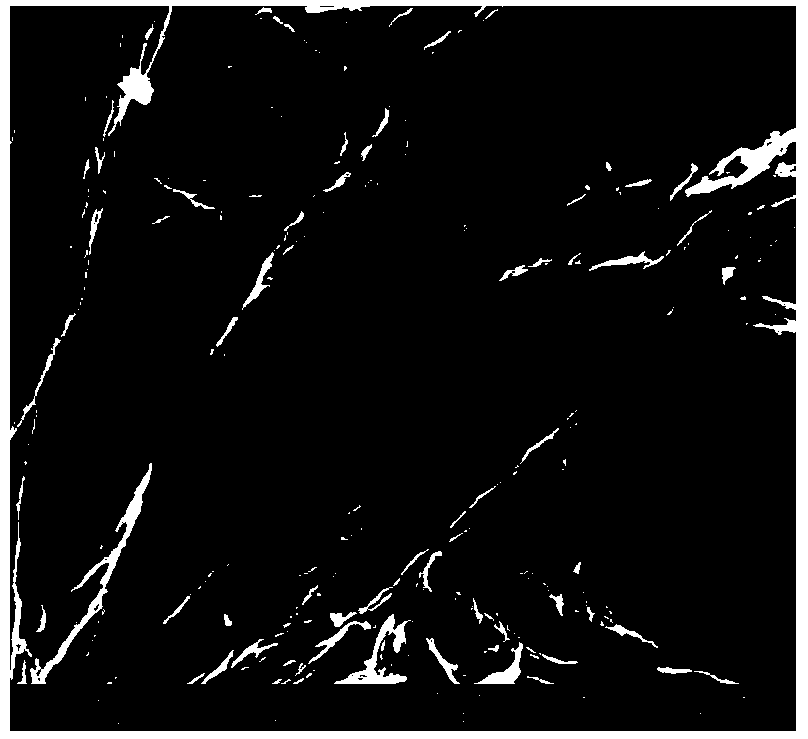

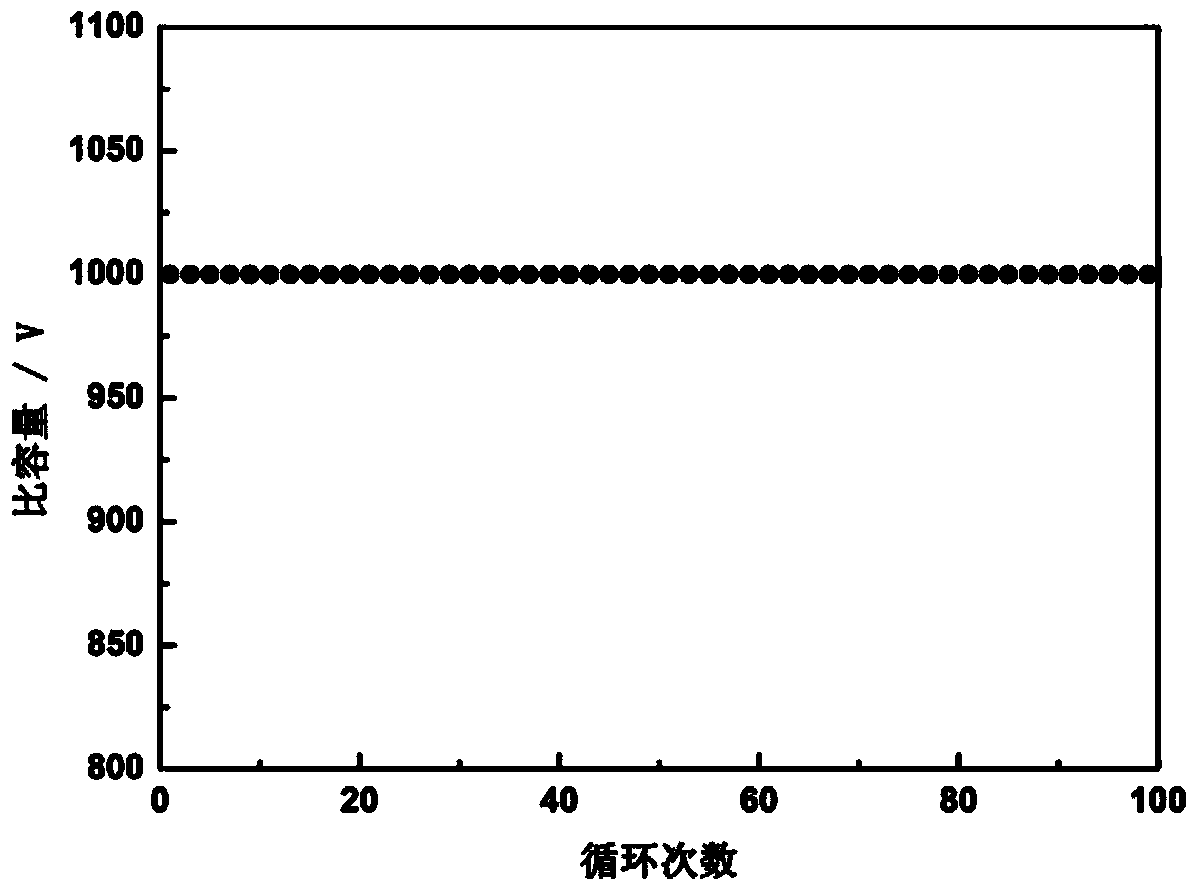

Embodiment 1

[0035] 0.1 g of polyaniline and 0.1 g of ferric hydroxide were deposited or grown on the surface of a filter paper with a thickness of 20 microns and a mass of 0.02 g by liquid phase deposition, and dried to obtain a catalyst precursor / nitrogen-containing conductive polymer composite paper sheet. The obtained catalyst precursor / nitrogen-containing conductive polymer composite paper sheet was put into a potassium hydroxide solution containing 0.2 gram of urea (0.6 gram of potassium hydroxide) and immersed for a period of time, then placed in a protective nitrogen atmosphere, and carbonized at 800°C and nitriding for 5 hours to obtain a nitrogen-containing 18 wt% metal nitride / nitrogen-containing hierarchical hole carbon composite electrode with a three-dimensional carbon fiber network structure as a self-supporting body. The electrode prepared in this example and the lithium negative electrode were assembled into a button battery, and a constant current charge and discharge test...

Embodiment 2

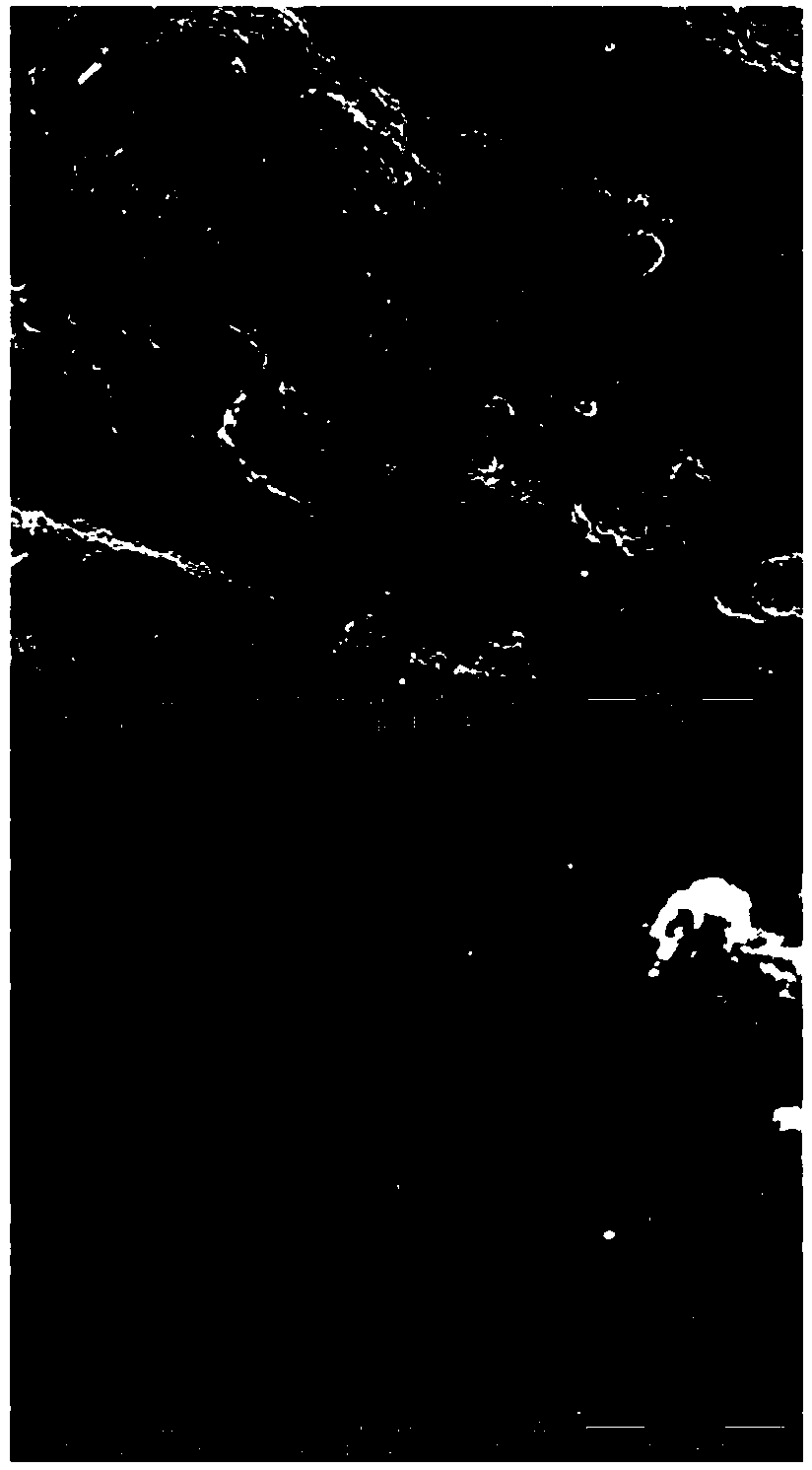

[0041] 0.1 g of polydopamine and 0.05 g of cobalt oxide were deposited or grown on the surface of a printing paper with a thickness of 50 microns and a mass of 0.075 g by liquid phase deposition, and dried to obtain a catalyst precursor / nitrogen-containing conductive polymer composite paper sheet. The obtained catalyst precursor / nitrogen-containing conductive polymer composite paper sheet was put into a sodium hydroxide solution containing 0.3 gram of melamine (0.4 gram of sodium hydroxide) and immersed for a period of time, then placed in a protective nitrogen atmosphere, and carbonized at 900°C and nitriding for 10 hours to obtain a nitrogen-containing 25 wt% metal nitride / nitrogen-containing hierarchical hole carbon composite electrode with a three-dimensional carbon fiber network structure as a self-supporting body. The electrode prepared in this example and the lithium negative electrode were assembled into a button battery, and a constant current charge and discharge test...

Embodiment 3

[0043] 0.05 g of polypyrrole and 0.2 g of nickel oxide were deposited or grown on the surface of writing paper with a thickness of 10 microns and a mass of 0.05 g by liquid phase deposition, and dried to obtain a catalyst precursor / nitrogen-containing conductive polymer composite paper sheet. The obtained catalyst precursor / nitrogen-containing conductive polymer composite paper sheet was put into a lithium hydroxide solution containing 0.2 gram of melamine (0.5 gram of lithium hydroxide) and immersed for a period of time, then placed in a protective nitrogen atmosphere, and carbonized at 700 ° C and nitriding for 2 hours to obtain a nitrogen-containing 15 wt% metal nitride / nitrogen-containing hierarchical hole carbon composite electrode with a three-dimensional carbon fiber network structure as a self-supporting body. The electrode prepared in this example and the lithium negative electrode were assembled into a button battery, and a constant current charge and discharge test w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com