A kind of preparation method of core-shell structure zns/ni2p composite microsphere

A core-shell structure and composite technology, which is applied in the field of photocatalysis to achieve the effects of simple and easy-to-obtain raw materials, superior photocatalytic performance, and easy-to-control conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A core-shell structure of ZnS / Ni 2 The preparation method of P complex microspheres comprises the following steps:

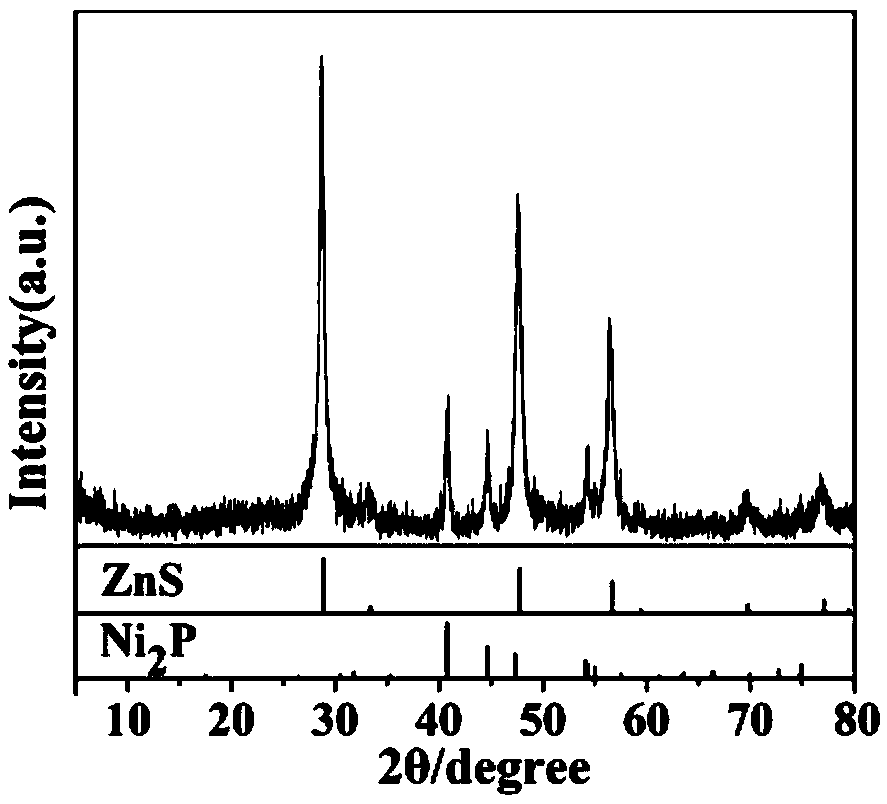

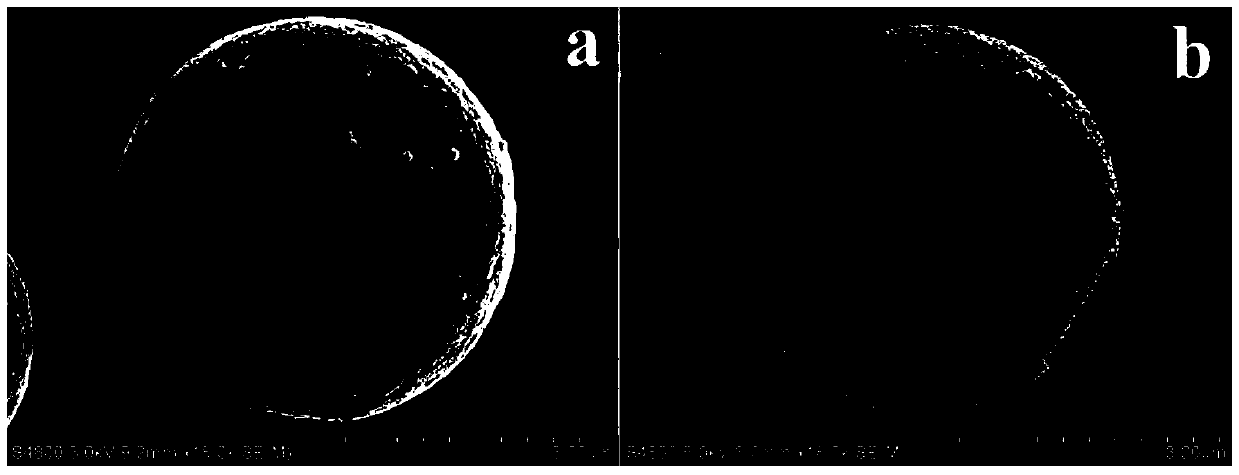

[0027] 1) Preparation of zinc sulfide microspheres: 1 mmol Zn(CH 3 COO) 2 ·2H 2 O was dissolved in 15 mL of distilled water. Under magnetic stirring, 0.45 mL of glacial acetic acid was added. After magnetic stirring for a while, 1.5 mmol of thiourea was added to the system. In the reaction kettle of polytetrafluoroethylene, the reaction was carried out at 170 °C in a constant temperature oven for 8 hours. After the reaction was completed, it was cooled naturally, centrifuged, and the samples were washed with distilled water and absolute ethanol, respectively, at 60 °C in a vacuum drying box Dry for 6h to get white powder, refer to image 3 , the white powder was characterized by X-ray diffractometer and scanning electron microscope, and the obtained product was zinc sulfide with microsphere structure;

[0028] 2) Preparation of ZnS / Ni 2 P composite ...

Embodiment 2

[0031] Using the zinc sulfide powder prepared in step 1) in Example 1 as the raw material, in step 2), no sodium dodecyl sulfate (SDS) was added, and other conditions remained unchanged. Through characterization analysis, the obtained product contained a small amount of impurities , and its morphology is comparable to that of ZnS / Ni in Example 1 2 P composite microspheres are more messy.

Embodiment 3

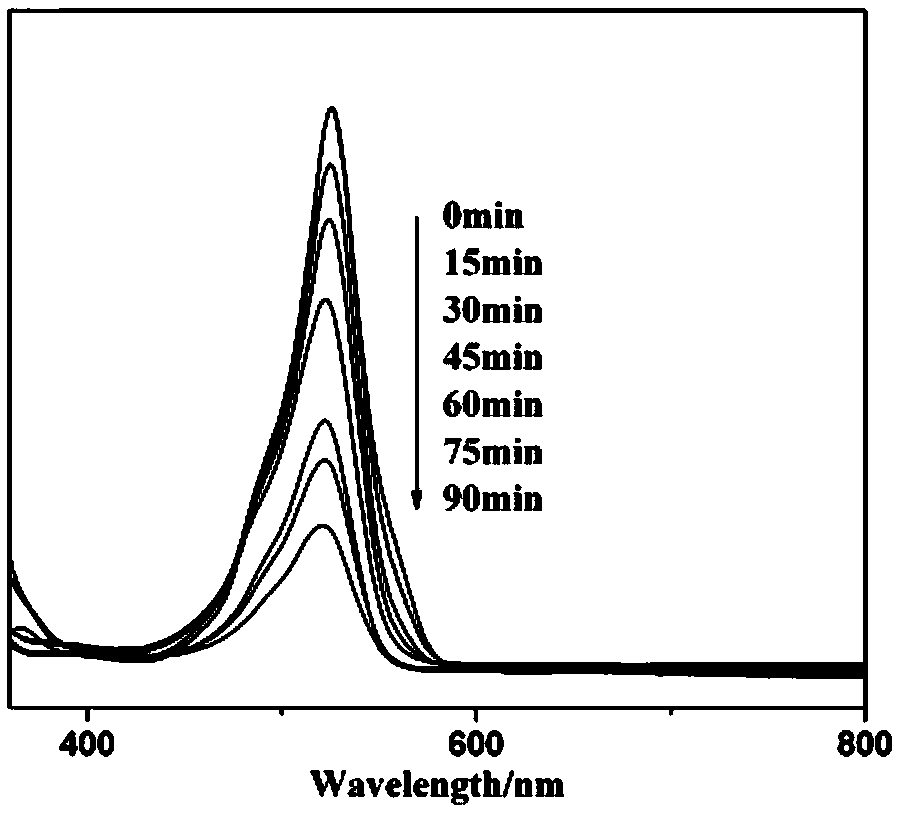

[0033] Using the zinc sulfide powder prepared in step 1) in Example 1 as a raw material, in step 2), the amount of citric acid was changed to 0.15 mmol, and other conditions remained unchanged. Through characterization analysis, the obtained product is ZnS / Ni 2P composite microspheres. Using pyrrole red B solution as the photocatalytic degradation dye, the degradation rate reached 76% after 90 min of illumination.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com