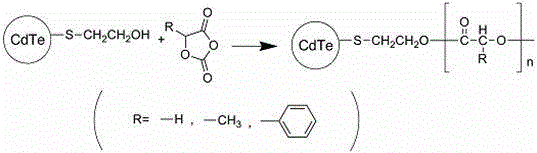

Poly-a-hydroxy acid modified CdTe quantum dot and preparation method thereof

A technology of quantum dots and hydroxy acids, which is applied in the field of modifying CdTe quantum dots with poly a-hydroxy acids, to achieve the effects of simple and convenient operation, good water solubility and stability, and excellent fluorescence properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] A preparation method of polylactic acid modified CdTe quantum dots, the operation steps are as follows:

[0014] (1) Prepare sodium hydride telluride NaHTe solution as tellurium source;

[0015] (2) In a 50mL single-necked flask, mix 30mg of cadmium chloride, 240mg of trisodium citrate and 60mg of mercaptoethanol, add 35mL of deionized water, and exhaust with argon;

[0016] (3) Quickly inject 3 mL of sodium telluride hydride NaHTe solution with a concentration of 0.02 mg / mL into the mixed solution described in step (2), heat and reflux at 70°C for 1 hour, add an appropriate amount of absolute ethanol, and centrifuge. Freeze-drying for 24 hours to obtain CdTe quantum dots modified with mercaptoethanol;

[0017] (4) Mix L-lactic oxyanhydride and mercaptoethanol-modified CdTe quantum dots at a ratio of 1:1, add 10 mL of chloroform, add 2.1 mg of 4-dimethylaminopyridine, and use the hydroxyl groups at the end of the CdTe quantum dots to make L- Lactic acid oxyanhydride w...

Embodiment 2

[0020] A preparation method of polylactic acid modified CdTe quantum dots, the operation steps are as follows:

[0021] (1) Prepare sodium hydride telluride NaHTe solution as tellurium source;

[0022] (2) In a 50mL single-necked flask, mix 30mg of cadmium chloride, 270mg of trisodium citrate and 60mg of mercaptoethanol, add 35mL of deionized water, and exhaust with argon;

[0023] (3) Rapidly inject 3 mL of sodium telluride hydride NaHTe solution with a concentration of 0.02 mg / mL into the mixed solution described in step (2), heat and reflux at 90°C for 1 hour, add appropriate excess ethanol, and centrifuge, Freeze-drying for 24 hours to obtain CdTe quantum dots modified with mercaptoethanol;

[0024] (4) Mix L-lactic acid oxyanhydride and CdTe quantum dots modified by mercaptoethanol at a ratio of 6:1, add 10 mL of chloroform, add 6 mg of 4-dimethylaminopyridine, and make use of the hydroxyl groups at the end of CdTe quantum dots to make L- Lactic acid oxyanhydride is rin...

Embodiment 3

[0027] A preparation method of polylactic acid modified CdTe quantum dots, the operation steps are as follows:

[0028] (1) Prepare sodium hydride telluride NaHTe solution as tellurium source;

[0029] (2) In a 50mL single-necked flask, mix 30mg of cadmium iodide, 270mg of trisodium citrate and 90mg of mercaptoethanol, add 35mL of deionized water, and exhaust with argon;

[0030] (3) Rapidly inject 3 mL of sodium telluride hydride NaHTe solution with a concentration of 0.02 mg / mL into the mixed solution described in step (2), heat and reflux at 80°C for 2 hours, add appropriate excess ethanol, and centrifuge. Freeze-drying for 24 hours to obtain CdTe quantum dots modified with mercaptoethanol;

[0031] (4) Mix L-lactic oxyanhydride and mercaptoethanol-modified CdTe quantum dots at a ratio of 8:1, add 15 mL of chloroform, add 13 mg of 4-dimethylaminopyridine, and make use of the terminal hydroxyl groups of CdTe quantum dots to make L- Lactic acid oxyanhydride is ring-opened a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com