A glass fiber reinforced polyphenylene sulfide compound with high bonding strength to metal and preparation method thereof

A technology of polyphenylene sulfide and polyphenylene sulfide resin, which is applied in the field of processing and preparation of polyphenylene sulfide resin, can solve the problems of high dielectric constant, affecting computer numerical control processing, and easy yellowing, and achieve low dielectric performance and Dissipation Factor, Excellent Metal Bonding Strength, Ease of Handling and Control Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

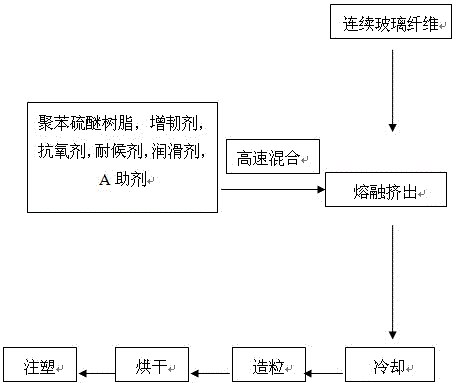

[0052] 81.2 parts by weight of polyphenylene sulfide resin, 13 parts by weight of ethylene-butyl acrylate-glycidyl methacrylate copolymer, 1.0 parts by weight of high molecular weight hindered amine light stabilizer, 0.25 parts by weight of pentaerythritol Dodecylthiopropyl ester (412S), 0.25 parts by weight of three [2.4-di-tert-butylphenyl] phosphite, 0.3 parts by weight of pentaerythritol stearate; 4 parts by weight of A auxiliary agent; in a high-speed mixer Press the above components at room temperature figure 1 The process route is mixed evenly, and then produced in a twin-screw extruder. Processing conditions: material mixing speed: 500 rpm; temperature in zone 1: 200°C, temperature in zone 2: 270°C, temperature in zone 3: 260°C, temperature in zone 4: 260°C, temperature in zone 5: 230°C, temperature in zone 6: Zone temperature: 230°C, zone 7 temperature: 230°C, zone 8 temperature: 260°C, zone 9 temperature: 280°C, host speed: 400 rpm.

Embodiment 2

[0054] 73.2 parts by weight of polyphenylene sulfide resin, 11 parts by weight of maleic anhydride-ethylene-octene copolymer, 0.8 parts by weight of low molecular weight stereo hindered amine light stabilizer, 0.25 parts by weight of 4,4' -[1,1'-biphenyl]ylidene diphosphonic acid-tetrakis[2,4-di-tert-butylphenyl]ester (PEPQ), 0.25 parts by weight of tris[2.4-di-tert-butylphenyl] Phosphate ester, the mixture of stearic acid and calcium stearate of 0.3 weight part; A auxiliary agent weight part 4; In high-speed mixer, above-mentioned component is pressed at room temperature figure 1 The process route is mixed evenly, and then produced in a twin-screw extruder. Continuous glass fiber is added from the middle of the twin-screw, and the glass fiber content is controlled to be 10. Processing conditions: material mixing speed: 500 rpm; temperature in zone 1: 200°C, temperature in zone 2: 300°C, temperature in zone 3: 290°C, temperature in zone 4: 280°C, temperature in zone 5: 210°C, ...

Embodiment 3

[0056] The polyphenylene sulfide resin of 66.6 parts by weight, the maleic anhydride-ethylene-octene copolymer of 9 parts by weight, the benzotriazole ultraviolet absorber of 0.6 parts by weight, the 4,4'-[1, 1'-biphenyl]ylidene diphosphonic acid-tetrakis[2,4-di-tert-butylphenyl]ester (PEPQ), 0.2 parts by weight Tris[2.4-di-tert-butylphenyl]phosphite, 0.4 The montan wax of weight part; A auxiliary agent weight part 3; In high-speed mixer, above-mentioned component is pressed at room temperature figure 1 The process route is mixed evenly, and then produced in a twin-screw extruder. Continuous glass fiber is added from the middle of the twin-screw, and the glass fiber content is controlled to 20%. The mixing speed of the material is: 500 rpm; the temperature of the first zone: 200°C, the temperature of the second zone: 300°C, the temperature of the third zone: 290°C, the temperature of the fourth zone: 280°C, the temperature of the fifth zone: 210°C, the temperature of the sixth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com