A kind of low surface energy biological antibacterial antifouling coating with surface microstructure and preparation method thereof

A low surface energy, antifouling coating technology, applied in antifouling/underwater coatings, coatings, paints containing biocides, etc. And the effect of renewable antibacterial properties, enhanced hydrophobicity, good abrasion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

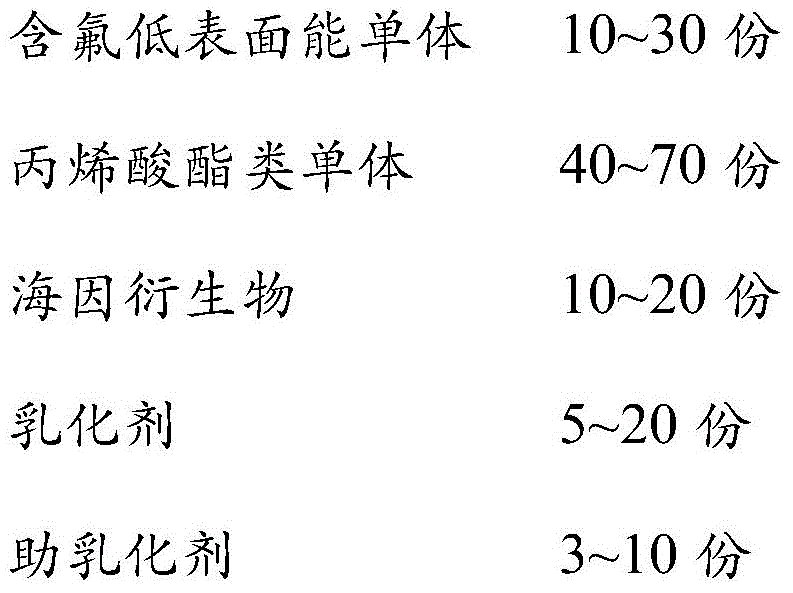

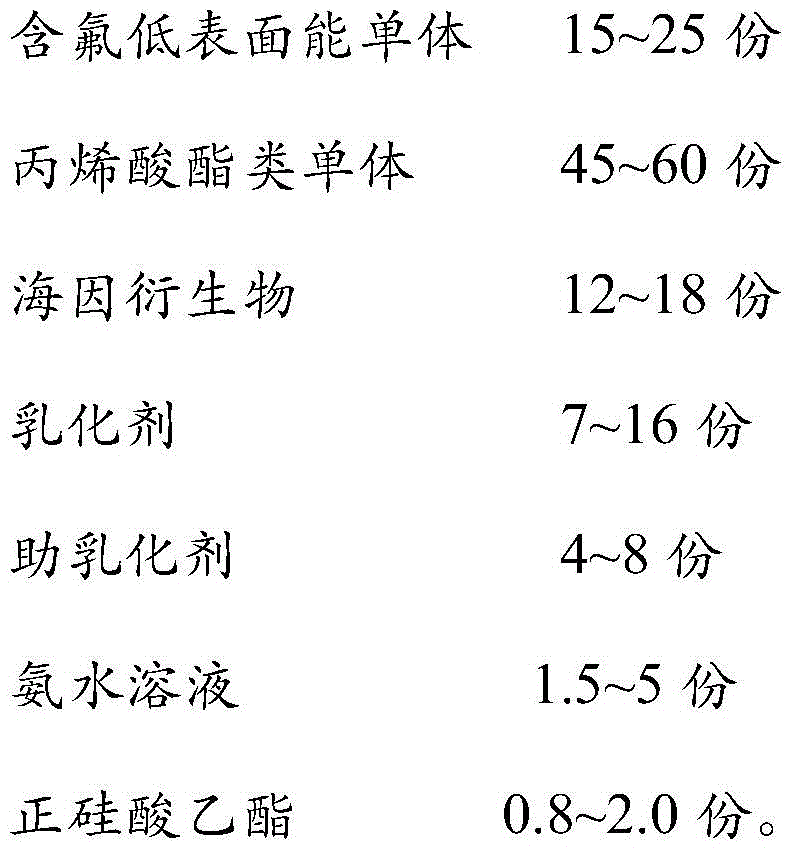

Method used

Image

Examples

Embodiment 1

[0036] A kind of preparation method of the low surface energy biological antibacterial antifouling coating with surface microstructure of the present embodiment, comprises the steps:

[0037] (1) 2g of hexafluorobutyl acrylate (CH 2 =CHCOOCH 2 CF 2 CFHCF 3 ), Harbin Xuejia Fluorosilicon Chemical Co., Ltd.), 7g methyl methacrylate (CH 2 =C(CH 3 ) COOCH 3 , Aladdin Reagent), 1.5g of 3-allyl-5,5-dimethylhydantoin (ADMH) was put into a stoppered glass test tube and mixed evenly, then added 1.0g Span80-Tween60 (mass ratio 1:9) composite emulsifier (chemically pure, Tianjin Guangfu Science and Technology) and 0.5g isobutanol (analytical pure, Tianjin Guangfu Science and Technology), form a monomer oil phase / emulsifier / co-emulsifier to be titrated system, fully ultrasonically disperse for 20min under ultrasonic, and set aside;

[0038] (2) Pipette 0.3g mass concentration of 10% ammonia solution with a microburette, and slowly add it dropwise to the above-mentioned system. Whe...

Embodiment 2

[0044] A kind of preparation method of the low surface energy biological antibacterial antifouling coating with surface microstructure of the present embodiment, comprises the steps:

[0045] (1) 2g of dodecafluoroheptyl acrylate (CH 2 =CHCOOCH 2 CF(CF 3 ) CFHCF (CF 3 ) 2 ), Harbin Xuejia Fluorosilicon Chemical Co., Ltd.), 8g ethyl acrylate (CH 2 =CHCOOCH 2 CH 3 , Aladdin reagent), 2g of 3-allyl-5,5-dimethylhydantoin (ADMH, the preparation method is the same as in Example 1) and put into a stoppered glass test tube and mix evenly, then add 1.05g emulsifier AOT (chemically pure, aladdin Reagent) and 1.2g n-propanol (analytical grade, Tianjin Guangfu Science and Technology Co., Ltd.) to form a monomer oil phase / emulsifier / co-emulsifier system to be titrated, fully ultrasonically dispersed for 10min under ultrasound, and set aside;

[0046] (2) Pipette 0.5 g mass concentration of 10% ammonia solution with a microburette, and slowly add it dropwise to the above-mentione...

Embodiment 3

[0050] A kind of preparation method of the low surface energy biological antibacterial antifouling coating with surface microstructure of the present embodiment, comprises the steps:

[0051] (1) 4g of dodecafluoroheptyl methacrylate (CH 2 =CHCOOCH 2 CF(CF 3 ) CFHCF (CF 3 ) 2 ), Harbin Xuejia Fluorosilicon Chemical Co., Ltd.), 8g butyl acrylate (CH 2 =CHCOOCH 2 CH 2 CH 2 CH 3 , Aladdin reagent), 3.2g of 3-allyl-5,5-dimethylhydantoin (ADMH, the preparation method is the same as in Example 1) and put into a stoppered glass test tube and mix uniformly, then add 1.5g emulsifier AOT (chemically pure , Aladdin Reagent) and 1.5g isopropanol (analytical grade, Tianjin Guangfu Science and Technology) to form a monomer oil phase / emulsifier / co-emulsifier system to be titrated, fully ultrasonically dispersed for 30min under ultrasonic, and set aside;

[0052] (2) Pipette 0.3g mass concentration of 10% ammonia solution with a microburette, and slowly add it dropwise to the abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com