Supplementation and enzymatic conversion based ultrasonic-assisted preparation method of L-tyrosine

A tyrosinase method and ultrasonic technology, applied in the biological field, can solve the problems of low efficiency, high cost and long reaction time of L-tyrosine, and achieve the effects of simple process flow, low cost and short production cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

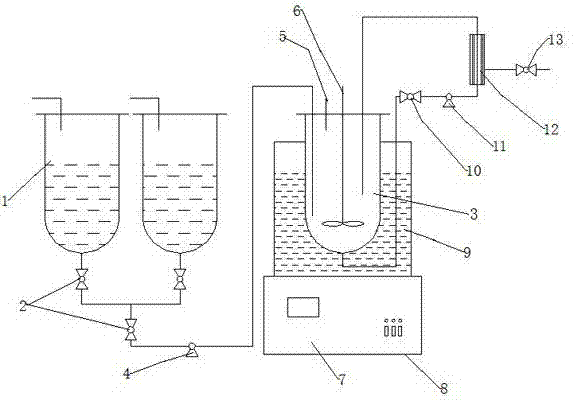

[0027] The main body of the reaction device of the L-tyrosinase conversion preparation method includes: a feeding device, a reaction device and an ultrasonic treatment device. The feeding device includes a feeding tank 1, a feeding outlet valve 2, and a feeding pump 4; the reaction device includes Exhaust pipe 5, agitator 6, reaction tank 3, discharge valve 10, liquid outlet pump 11, filter 12, liquid outlet valve 13; ultrasonic device includes display 7, control panel 8 and tank body 9, reaction tank 3 is placed In the tank body 9 of the ultrasonic device, there are two feeding tanks 1, phenol is added in one feeding tank 1, and a mixture of sodium pyruvate, ammonium chloride and pyridoxal phosphate is added in the other feeding tank 1. solution.

[0028] The raw materials and strains used in the present invention can be purchased from the market.

Embodiment 1

[0030] A preparation method for feeding and ultrasonically assisted L-tyrosinase conversion, said preparation method comprising the following steps:

[0031] a) Citrobacter freundii Citrobacter freundii ATCC 8090 obtained resting cells after slant-activated seeds were cultured and fermented in the fermentation medium; the fermentation medium was 3 g / L of yeast extract, 1 g / L of L-tyrosine, 1 g / L of dipotassium hydrogen phosphate, Magnesium sulfate heptahydrate 0.5g / L, ferrous sulfate heptahydrate 0.01g / L and pyridoxine hydrochloride 0.05g / L;

[0032] b) Add the resting cells in step a) into the reaction tank, the pH of the potassium phosphate buffer in the reaction tank is 8, 100mM, and the amount of the resting cells is 10 10 CFU / mL, the reaction tank is placed in the tank of the ultrasonic device, and the action time is 15 minutes; the ultrasonic power is 5w, and the temperature is 8°C

[0033] c) Add phenol, sodium pyruvate, ammonium chloride and pyridoxal phosphate in ...

Embodiment 2

[0035] A preparation method for feeding and ultrasonically assisted L-tyrosinase conversion, said preparation method comprising the following steps:

[0036] a) Citrobacter freundii Citrobacter freundii ATCC 8090 obtained resting cells after slant activated seed culture and access to fermentation medium for fermentation; wherein, the fermentation medium was yeast extract 5g / L, L-tyrosine 2g / L, dipotassium hydrogen phosphate 2g / L, Magnesium sulfate heptahydrate 1g / L, ferrous sulfate heptahydrate 0.02g / L and pyridoxine hydrochloride 0.1g / L;

[0037] b) Add the resting cells in step a) into the reaction tank, the pH of the potassium phosphate buffer in the reaction tank is 9, 100mM, and the amount of the resting cells is 10 10 CFU / mL, the reaction tank is placed in the tank of the ultrasonic device, and the action time is 20min; the ultrasonic power is 85w, and the temperature is 10°C

[0038] c) Add phenol, sodium pyruvate, ammonium chloride and pyridoxal phosphate in the fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com