Polyvinyl alcohol/chitosan nano fiber film dressing containing nano silver and preparation thereof

A nanofiber membrane and chitosan nanotechnology, which can be used in fiber processing, medical science, textiles and papermaking, etc., can solve the problems of sponge dressings with small specific surface area, small porosity, wound cell adhesion and growth promotion, etc. , to achieve the effects of reducing shedding and agglomeration, improving stability, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Weigh 8g of polyvinyl alcohol and dissolve it in a mixed solvent of 92g of water and ethanol (the mass ratio of water:ethanol is 8:15) to prepare 100g of polyvinyl alcohol solution with a mass fraction of 8%. Weigh 0.24g chitosan and dissolve in 7.76g 1% acetic acid solution to prepare 8g mass fraction of 3% chitosan solution. In a boiling water bath, add 0.6ml of silver nitrate solution with a concentration of 400g / L dropwise into polyvinylpyrrolidone / N,N-dimethylformamide solution (0.6g of polyvinylpyrrolidone dissolved in 5.4mL of N,N -dimethylformamide), continue to insulate and stir for 6h to make nano-silver sol. After the above-mentioned polyethanol and chitosan solution are mixed, the above-mentioned nano-silver sol is added dropwise while stirring, and after the dropwise addition is completed, the stirring is continued for 2 hours to form a spinning solution. The nanofiber membrane was obtained by spinning with an electrospinning device, with a voltage of 10kV...

Embodiment 2

[0041] The concentration of the polyvinyl alcohol solution is enlarged to 20%, the sealing and crosslinking time of the nanofibrous membrane is extended to 2h, and other reagents and dosages and process conditions are unchanged, and Example 1 is repeated to obtain a composite nanofiber membrane sample containing nanosilver A 2 .

Embodiment 3

[0043]Expand the concentration of chitosan solution to 10%, extend the sealing crosslinking time of nanofibrous membrane to 3h, other reagents and consumption and process conditions are constant, repeat embodiment 1, promptly make composite nanofibrous membrane sample containing nano-silver A 3 .

[0044] The above samples were tested for their dissolution stability by the following method:

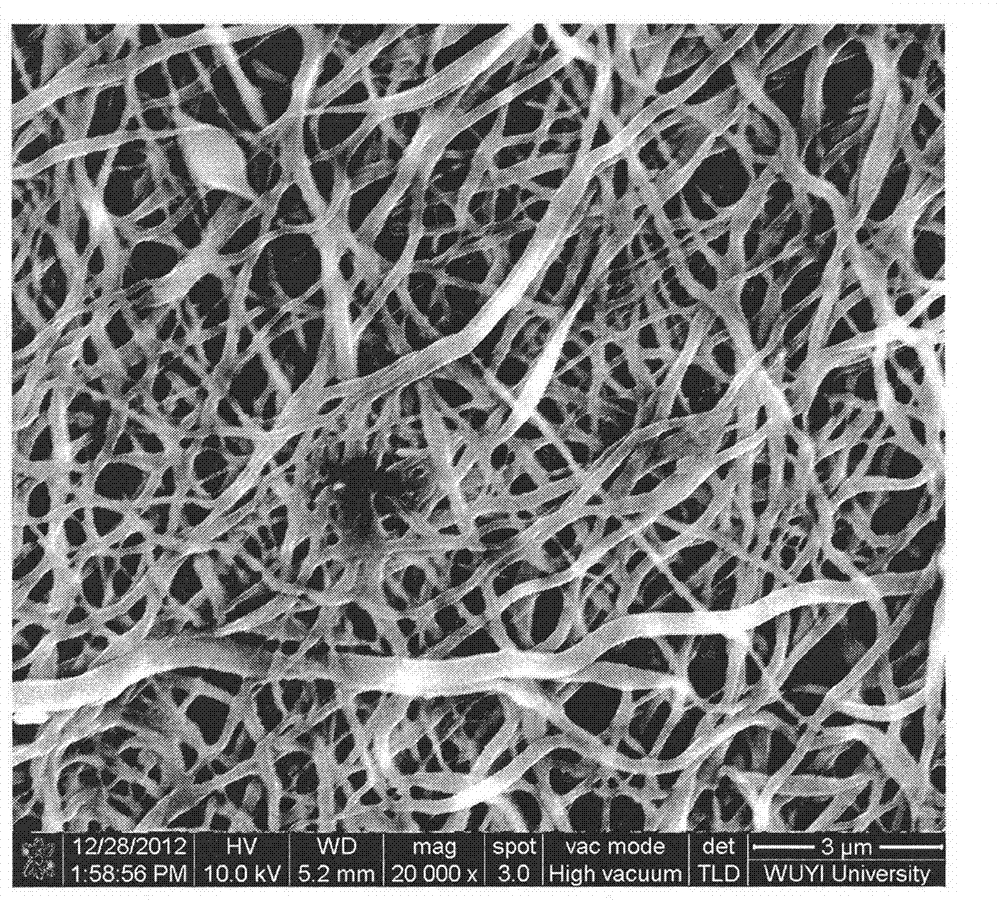

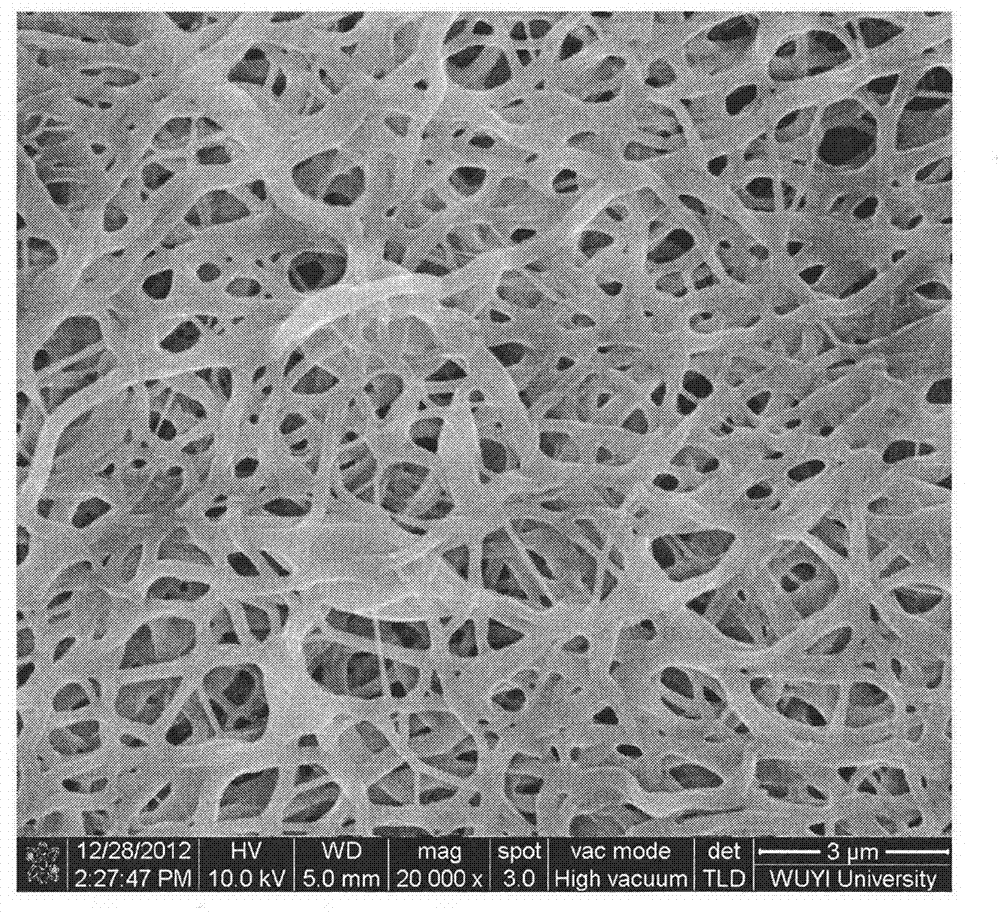

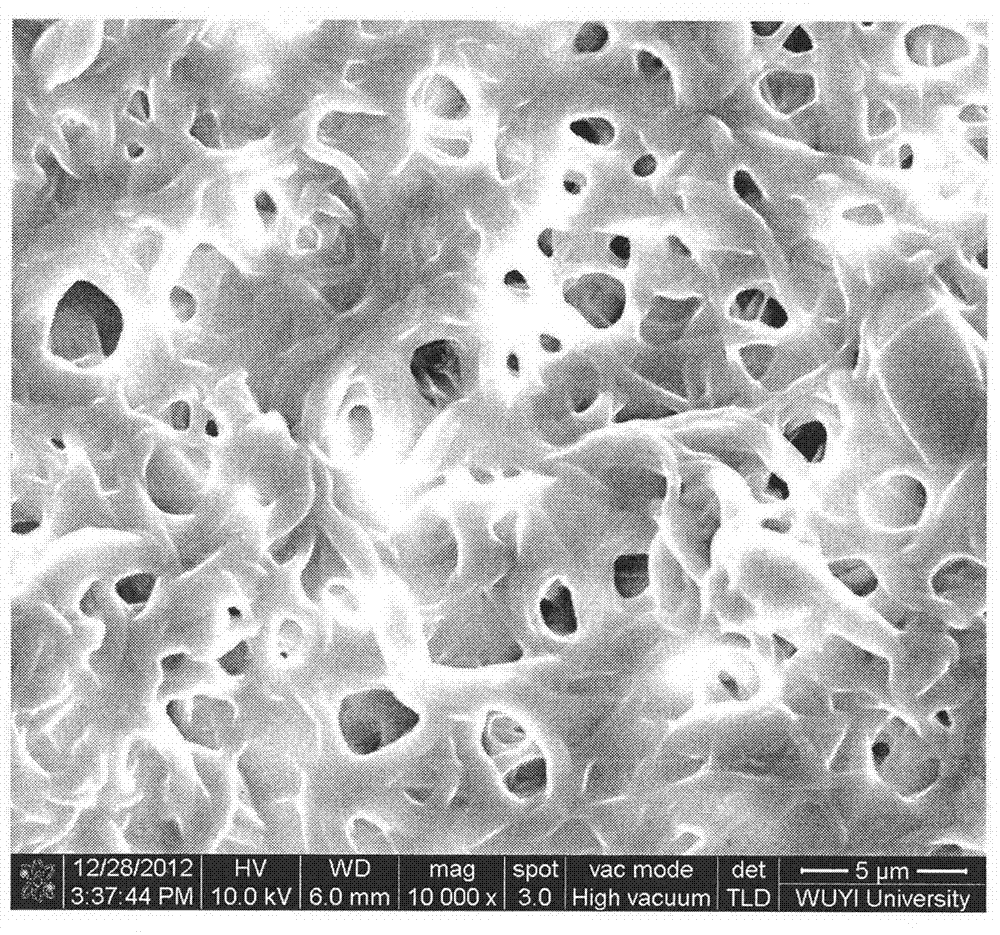

[0045] Soak the cross-linked samples in the PBS buffer solution of pH = 7.4 (concentration of 0.1mol / L KH 2 PO 4 solution and 0.1mol / L Na 2 HPO 4 The solution was mixed at a volume ratio of 1:4) for 1 h, washed with distilled water after being taken out, and dried in a vacuum oven at 40°C for 24 h. Then, use a scanning electron microscope SEM (NoVaNaVo SEM430, FEI Company) to observe the microscopic morphology of the sample before and after soaking in PBS buffer solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com