Bisamide chain organosilicon quaternary ammonium salt compound and preparation and application thereof

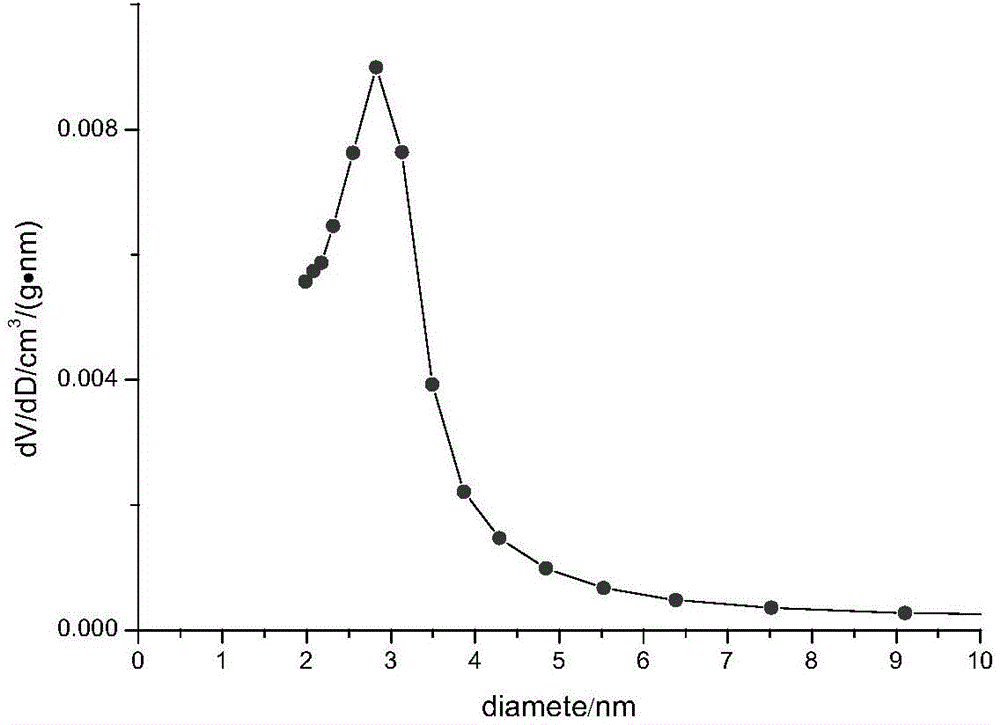

A technology of organosilicon quaternary ammonium salt and bisamide chain, which is applied in the field of surfactant and its preparation, can solve the problems of poor hydrothermal stability of molecular sieve and single structure of mesoporous molecular sieve, and achieves the improvement of pore volume and specific surface area, wide application The effect of uniform foreground and pore size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Bisamide chain organosilicon quaternary ammonium compound, its chemical structural formula is:

[0033]

[0034] where X - for I - , m is 6, n=3.

[0035] Preparation method: Add 7.6g of capric acid and 2.9g of N,N-bis(3-aminopropyl)methylamine into a 250mL three-necked flask, and then add 50mL of toluene. The temperature was raised to 140°C and the reaction was stirred for 17h. After the reaction was complete, cool down and evaporate toluene to dryness. Add 60 mL of n-hexane for recrystallization, and filter to obtain 9.3 g of white powder tertiary amine intermediate.

[0036] Add 0.7g of the above-mentioned intermediate and 0.72g of 3-iodopropyltrimethoxysilane into a 50mL round-bottomed flask, slowly heat to 100°C, and react for 36h. 0.83 g of the above-mentioned bisamide chain organosilicon quaternary ammonium salt compound.

Embodiment 2

[0038] Bisamide chain organosilicon quaternary ammonium compound, its chemical structural formula is:

[0039]

[0040] where X - for I - , m is 8, n=3.

[0041] Preparation method: Add 11.2g of lauric acid and 2.9g of N,N-bis(3-aminopropyl)methylamine into a 250mL three-necked flask, and then add 70mL of xylene. The temperature was raised to 165°C and the reaction was stirred for 10h. After the reaction was complete, cool down and evaporate xylene to dryness. 85 mL of n-hexane was added for recrystallization, and 10.5 g of a white solid tertiary amine intermediate was obtained by filtration.

[0042]Add 1.3g of the above-mentioned intermediate and 1.16g of 3-iodopropyltrimethoxysilane into a 50mL round-bottomed flask, slowly heat to 120°C, and react for 72h. 1.74 g of the above bisamide chain organic silicon quaternary ammonium salt compound was obtained.

Embodiment 3

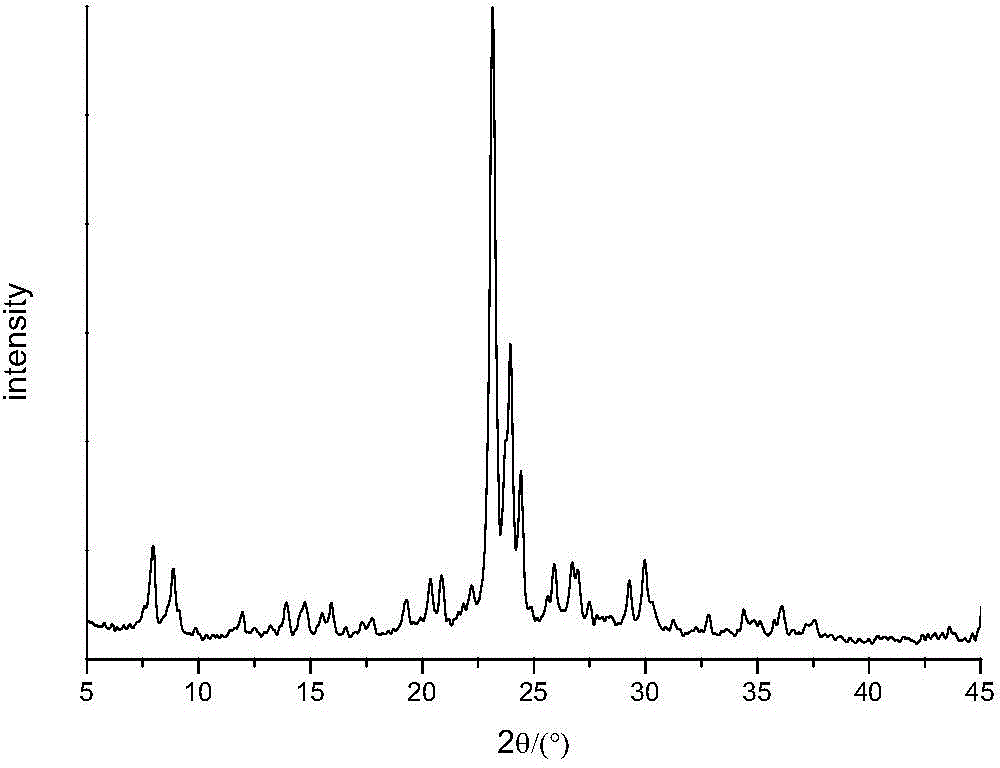

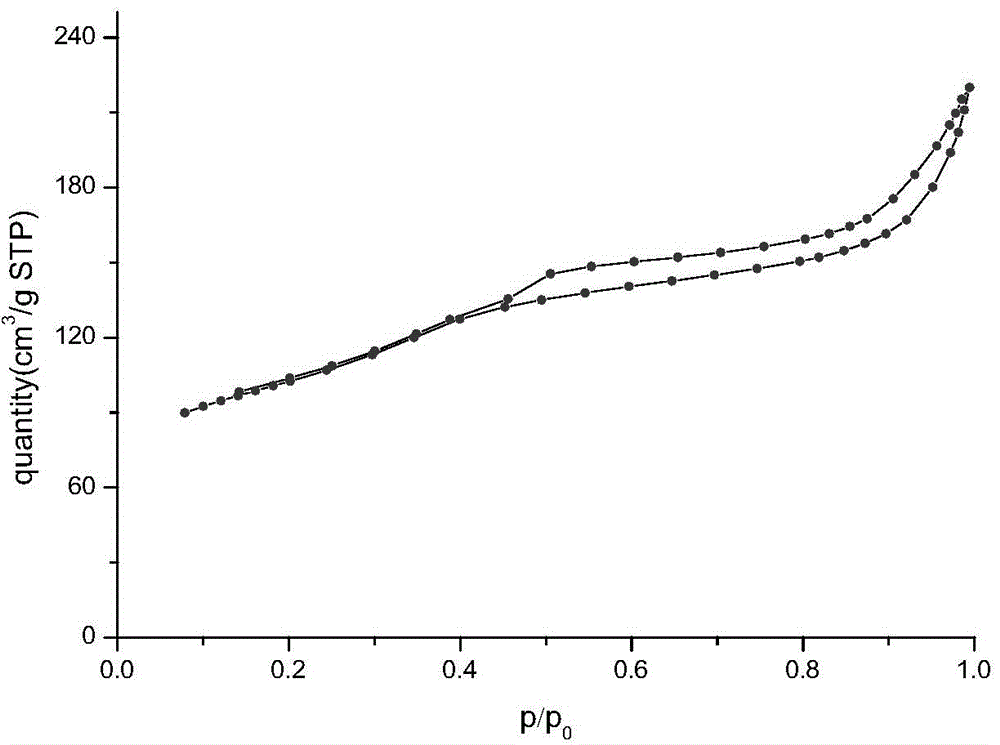

[0044] Synthesis of multi-level porous MFI structure zeolite molecular sieve: Add 0.163g aluminum isopropoxide, 8.13g tetrapropylammonium hydroxide, 8.33g tetrapropylammonium hydroxide and 60mL deionized water into a three-necked flask, stir for 30min, and wait for the dissolution to complete Then, 0.74 g of the bisamide chain organosilicon quaternary ammonium salt in Example 1 was added into the reaction flask in batches, and the stirring was continued at room temperature for 2 h. After the stirring was completed, the mixed solution in the reaction bottle was poured into a polytetrafluoro-lined stainless steel reaction kettle, and hydrothermally crystallized at 150° C. for 3 days. Cool, filter with suction, and wash repeatedly with deionized water until the pH is about 7. The product was dried at 100°C for 4h, and then calcined in a muffle furnace at 600°C for 5h. That is, the multi-level porous MFI structure zeolite molecular sieve, its BET surface area is 401.52m 2 g -1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com