Pole piece, energy storage device and preparation method of pole piece

A device and energy storage technology, applied in the field of electrochemistry, can solve the problems such as the inability to meet the requirements of light and thin electronic equipment, the decline of the electrical performance of the device, the large size and volume, etc., to achieve a small overall size, prevent electrolyte leakage, and maintain device structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The current collector selects a titanium plate with a thickness of about 40 μm, and cuts it into a rectangle of 8 cm×10 cm. The resin glue is selected from hot melt glue.

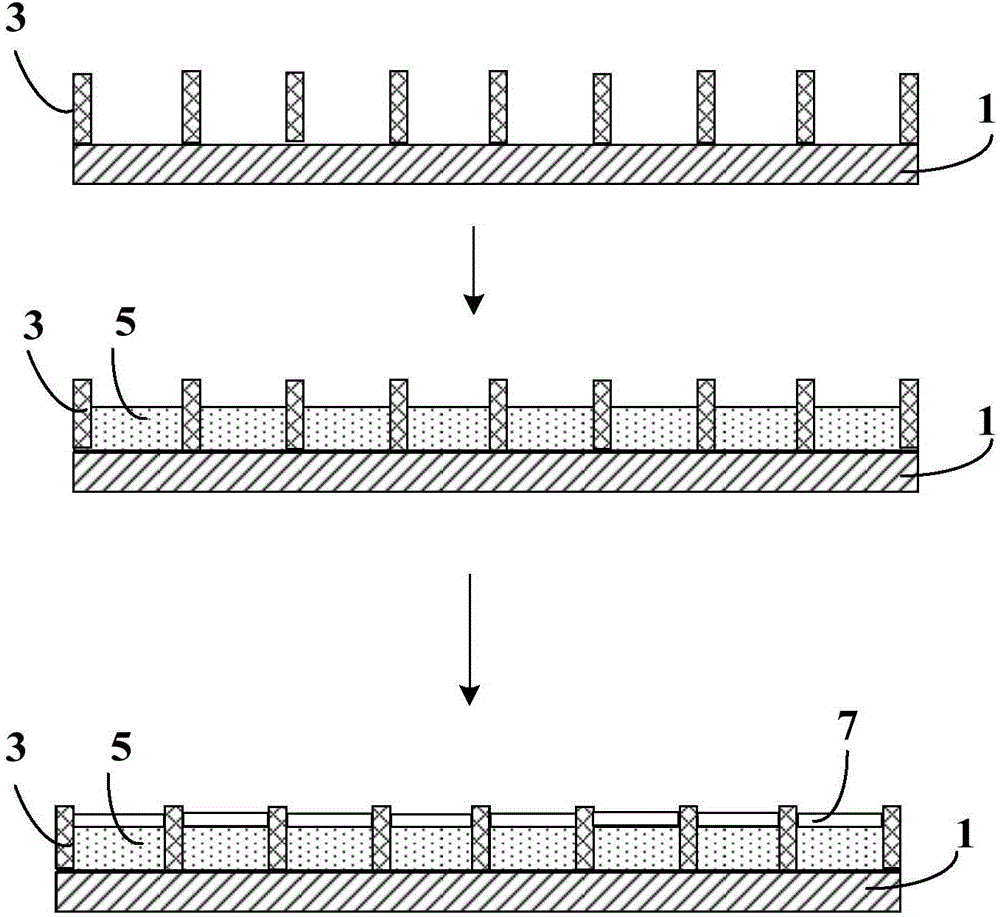

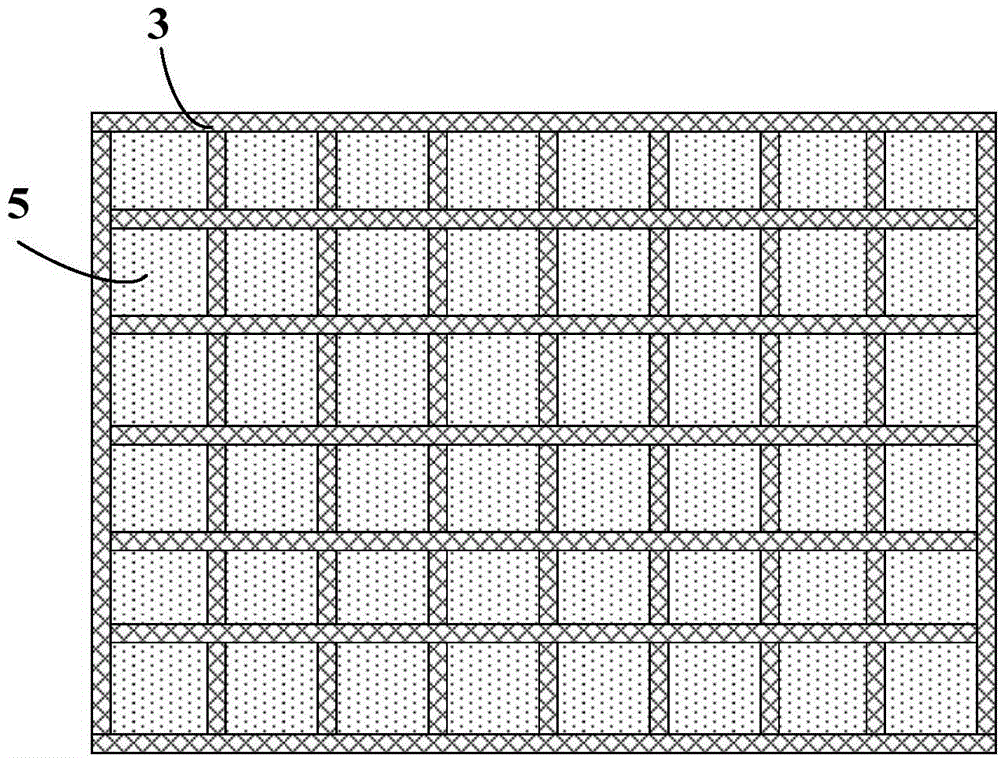

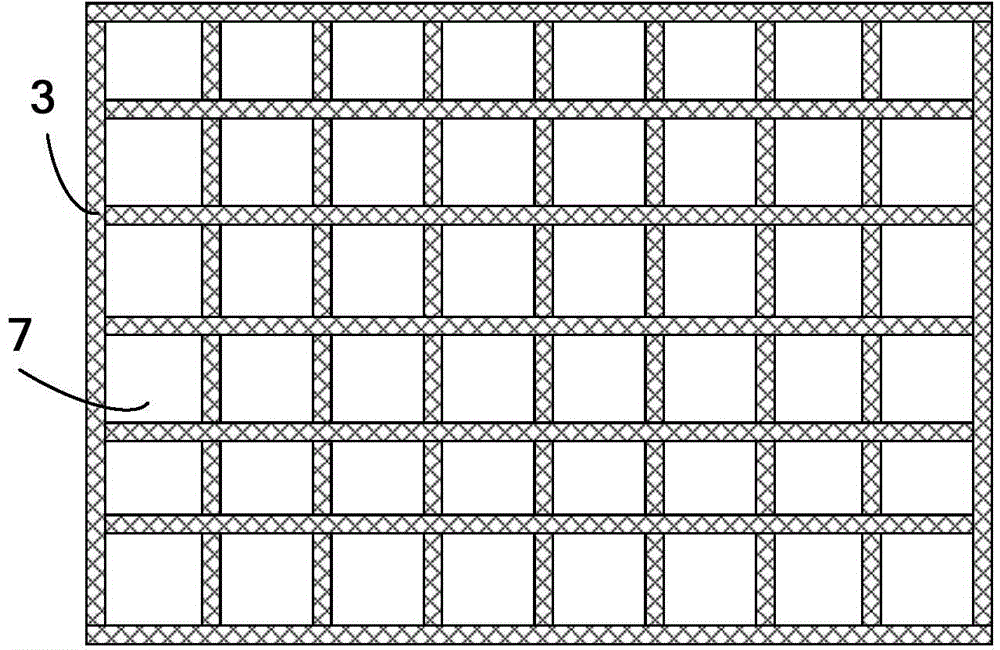

[0044] A1) Preparation of current collector with grid: Fix the current collector on the printing platform, select a three-dimensional printer with a layer height of 0.08mm, a peripheral layer thickness of 0.1mm, and a filling density of 90%, using hot-melt glue as a raw material. A hot melt adhesive grid is constructed on the current collector. At room temperature, place for 2-5 hours to dry and solidify. The grid formed on the current collector has a height of 0.2mm and a cell area of 0.3cm 2 .

[0045] A21) Deposit positive active material on the current collector with grids: prepare a 0.1M-3M manganese acetate solution, and ultrasonically treat it for 10-120 minutes to obtain a uniform manganese acetate solution. One side of the current collector obtained in step A1) is pasted with insulatin...

Embodiment 2

[0051] For the current collector, select a stainless steel sheet with a thickness of about 10 μm and a graphite paper with a thickness of 50 μm, and cut it into a rectangle of 10 cm×15 cm. Put the stainless steel sheet into a mixed solution of acetone and alcohol with a volume ratio of 1:3 for ultrasonic treatment for 0.5-3 hours, and finally dry it in an oven at 70-100°C for future use. The resin glue selects polyurethane for use.

[0052] B1) Preparation of current collector with grid: Take the above stainless steel sheet, seal one side with tape, and fix it on the printing table together with graphite paper, and select the line width, line spacing and thickness of 0.15mm, 5mm, and 1mm respectively Copper orifice plate is used for printing, add appropriate amount of polyurethane glue on the orifice plate, scrape it evenly with a scraper, make the polyurethane glue pass through the gap to form parallel lines on the stainless steel sheet and graphite sheet, and place it at roo...

Embodiment 3

[0058] The current collector chooses a titanium plate with a thickness of about 30 μm and an area of 10 cm×9 cm. The resin glue is selected from hot melt glue.

[0059] Pretreatment of the current collector: a microstructure of nickel cone arrays is formed on the surface of the current collector. In this embodiment, the nickel tip array structure is formed through the following steps:

[0060] Press the surface of the current collector down to the polishing pad, and perform chemical mechanical polishing under the action of the polishing liquid for 10 minutes. After taking it out, rinse it with deionized water for 2-3 times. After drying, the current collector is obtained. On one side of the current collector Paste the insulating glue for later use.

[0061] Mix 1.5mol / L nickel chloride solution, 1mol / L boric acid solution, and 1.0mol / L ammonium chloride solution. After mixing, the molar ratio of nickel chloride, boric acid and ammonium chloride is 1:0.8:1 , placed in a wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com