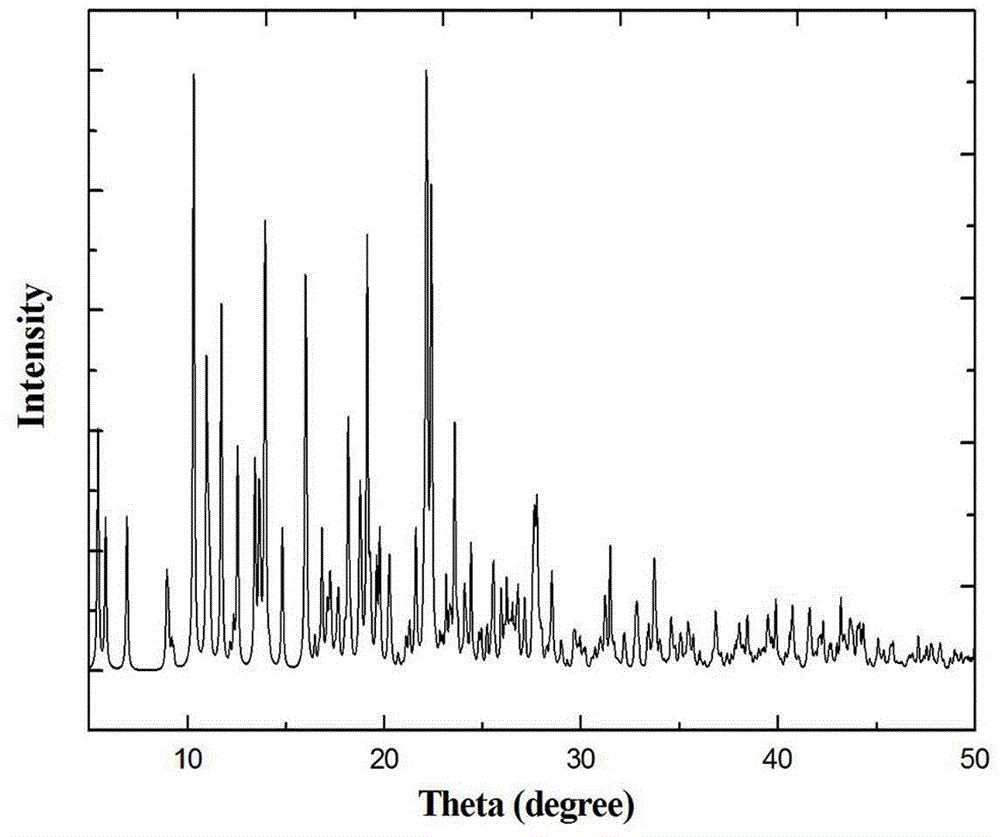

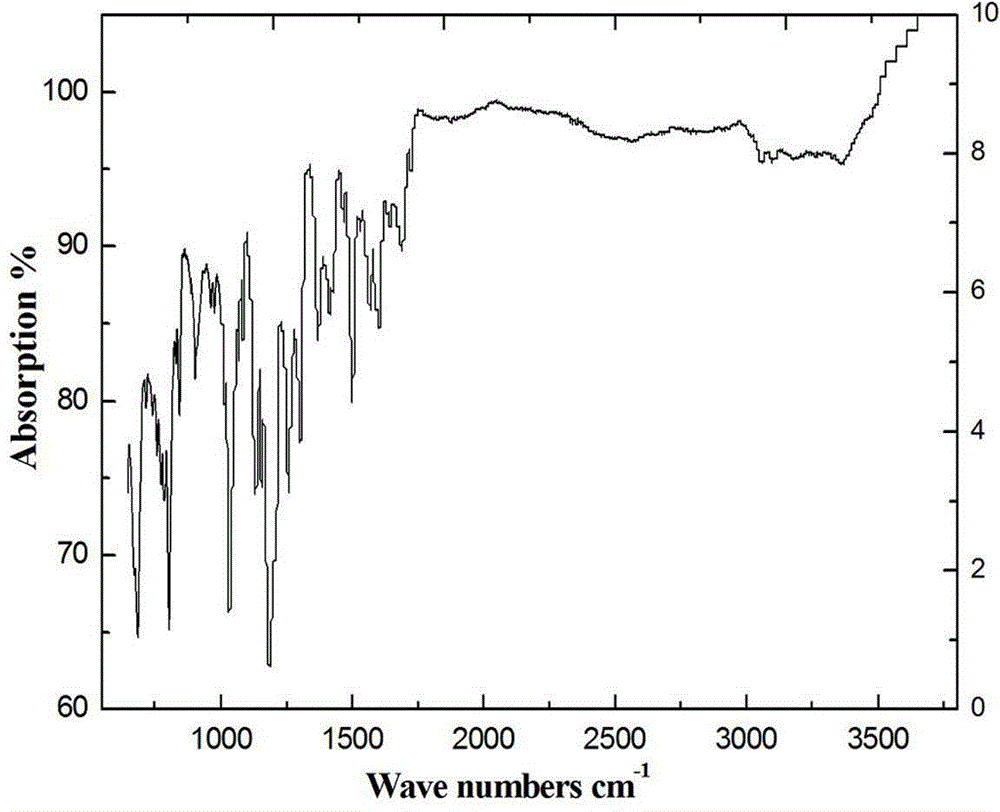

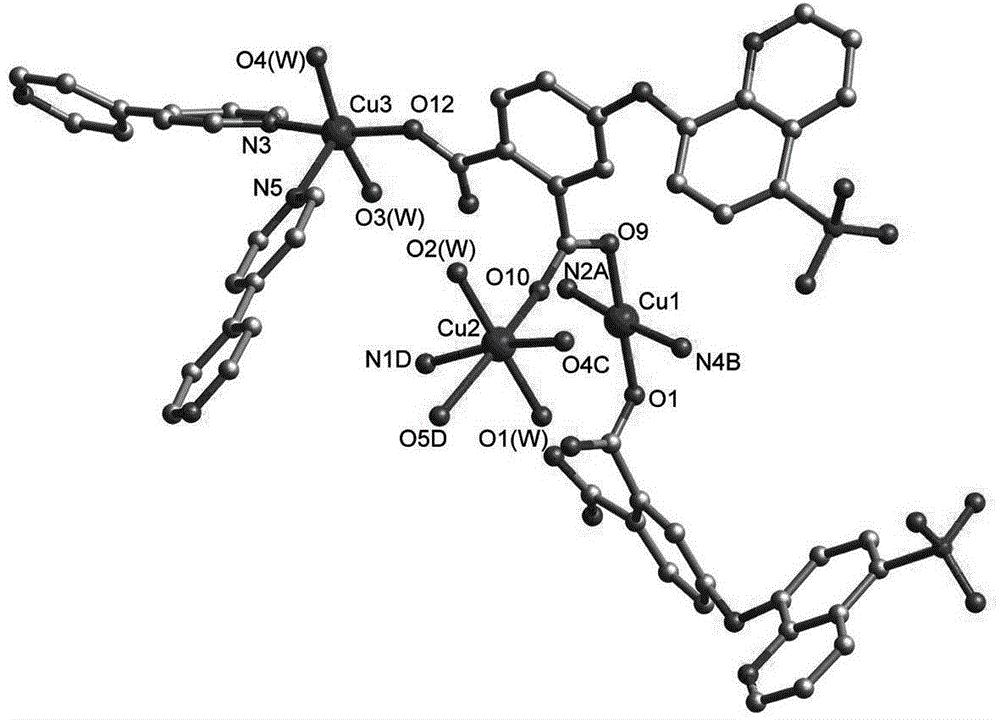

Frame compound catalyst material containing mixed valence Cu and preparation method thereof

A technology of framework compounds and mixed valence states, applied in the direction of organic compound/hydride/coordination complex catalysts, copper organic compounds, physical/chemical process catalysts, etc., can solve the problem of high corrosion in the liquid phase method and low activity in the gas phase method , hindering development and other issues, to achieve the effect of good crystallinity, easy recycling, and increased reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The preparation method of the framework compound catalyst material containing mixed valence Cu, the specific steps are as follows:

[0024] Step 1. Take the organic ligand 4-(5-sulfonyl) 8-hydroxyquinolyl-phthalic acid, and dissolve it in the mixed solution of water and organic solvent to obtain solution A, which is set aside; the organic solvent is DMF, methanol ethanol or DMSO, and the volume ratio of water to organic solvent is 0.5: 1~4:1;

[0025] Step 2, get divalent divalent copper source and 4,4'-bipyridine, described divalent copper source is Cu(OAc) 2 h 2 O, CuSO 4 · 5H 2 O or copper nitrate dihydrate is added to the solution A obtained in step 1, wherein the added divalent copper source, 4,4'-bipyridyl and organic ligand 4-(5-sulfonyl) 8-hydroxyquinoline The mol ratio of base-phthalic acid is 3:3:2, obtains solution B after stirring evenly, for subsequent use;

[0026] Step 3. Stir the solution B in step 2 with a magnetic stirrer at room temperature and...

Embodiment 1

[0030]A preparation method of a framework compound catalyst material containing mixed valence Cu, the specific steps are as follows:

[0031] Step 1, take the organic ligand 4-(5-sulfonyl) 8-hydroxyquinolyl-phthalic acid, dissolve it in the mixed solution of water and organic solvent, the organic solvent is methanol, and the volume of water and organic solvent Ratio is 0.5: 1.2, obtains solution A, for subsequent use;

[0032] The 4-(5-sulfonyl) 8-hydroxyquinolyl-phthalic acid has the following structural formula:

[0033]

[0034] Step 2, take divalent copper source Cu(OAc) 2 h 2 O and 4,4'-bipyridine were added to the solution A obtained in step 1, wherein the added divalent copper source, 4,4'-bipyridine and organic ligand 4-(5-sulfonyl)8- The mol ratio of hydroxyquinolinyl-phthalic acid is 3:3:2, obtains solution B after stirring, for subsequent use;

[0035] Step 3. Stir the solution B in step 2 with a magnetic stirrer at normal temperature and pressure for 20 min...

Embodiment 2

[0043] A preparation method of a framework compound catalyst material containing mixed valence Cu, the specific steps are as follows:

[0044] Step 1, take the organic ligand 4-(5-sulfonyl) 8-hydroxyquinolyl-phthalic acid, dissolve it in the mixed solution of water and organic solvent, the organic solvent is ethanol, and the volume of water and organic solvent Ratio is 4:1, obtains solution A, for subsequent use;

[0045] Step 2: Take divalent copper source CuSO 4 · 5H 2 O and 4,4'-bipyridine were added to the solution A obtained in step 1, wherein the added divalent copper source, 4,4'-bipyridine and organic ligand 4-(5-sulfonyl)8- The mol ratio of hydroxyquinolinyl-phthalic acid is 3:3:2, obtains solution B after stirring, for subsequent use;

[0046] Step 3. Stir the solution B in step 2 with a magnetic stirrer at normal temperature and pressure for 30 minutes, then adjust the pH value to 6 to obtain the precursor solution C, and set aside;

[0047] Step 4. Transfer th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com