Fast preparation method of high-transmittance silica aerogel film

A silica and aerogel technology, applied in chemical instruments and methods, inorganic chemistry, silicon compounds, etc., can solve the problems of poor film mechanical properties, poor mechanical properties, long preparation cycle, etc., and achieve simple equipment and high volatilization rate Slow, mechanically good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Add 9.25ml tetraethyl orthosilicate to 26.20ml ethylene glycol methyl ether, stir and mix evenly, then add 3.00ml deionized water and 1.60ml N,N-dimethylformamide, continue stirring for 0.5h, and finally Slowly add 64 μl of 1 mol / L ammonium fluoride solution dropwise, and then stir for 10 minutes to form a silica sol.

[0033] The glass substrate was ultrasonicated with chloroform, acetone, ethanol, and deionized water for 0.5 h, and finally rinsed with deionized water and dried for use.

[0034] Clamp the cleaned and dried glass substrate with the fixture of the pull coater, place the silica sol directly under the glass substrate, adjust the height of the fixture, set the dipping time to 30s, and the pulling rate to 1000μm / s. Pull to obtain a silica wet gel film.

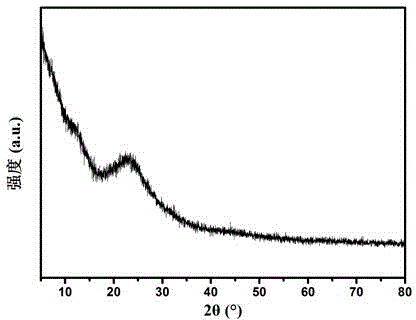

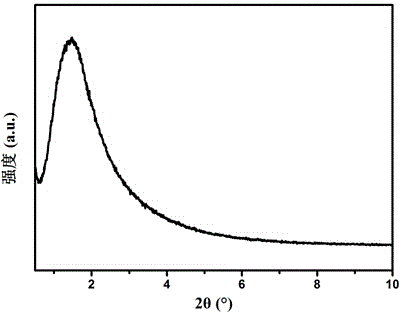

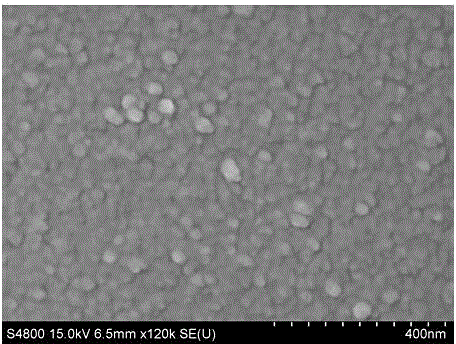

[0035] The obtained wet gel film was placed in a closed container in the atmosphere of ethylene glycol methyl ether and dried naturally. The thickness of the prepared silica airgel film was 115nm, the trans...

Embodiment 2

[0037] Add 9.40ml tetraethyl orthosilicate to 26.70ml ethylene glycol methyl ether, stir and mix evenly, then add 3.00ml deionized water and 0.80ml formamide, continue stirring for 0.5h, and finally slowly add 1 mol / L dropwise 66 μl of ammonium fluoride solution was stirred for 10 minutes to form a silica sol.

[0038] The glass substrate was ultrasonicated with chloroform, acetone, ethanol, and deionized water for 0.5 h, and finally rinsed with deionized water and dried for use.

[0039] Clamp the cleaned and dried glass substrate with the fixture of the pull coater, place the silica sol directly under the glass substrate, adjust the height of the fixture, set the dipping time to 30s, and the pulling rate to 1000μm / s. Pull to obtain a silica wet gel film.

[0040] The obtained wet gel film was placed in a closed container in the atmosphere of ethylene glycol methyl ether and dried naturally. The thickness of the prepared silica airgel film was 144nm, the transmittance was 90...

Embodiment 3

[0042] Add 11.70ml tetraethyl orthosilicate to 24.50ml ethanol, stir and mix evenly, then add 3.80ml deionized water and 1.50ml glycerol, continue stirring for 1h, and finally slowly add 1 mol / L ammonium fluoride solution dropwise 70 μl and stirred for 20 minutes to form a silica sol.

[0043] The glass substrate was ultrasonicated with chloroform, acetone, ethanol, and deionized water for 0.5 h, and finally rinsed with deionized water and dried for use.

[0044] Clamp the cleaned and dried glass substrate with the fixture of the pull coater, place the silica sol directly under the glass substrate, adjust the height of the fixture, set the dipping time to 20s, and the pulling rate to 750μm / s. Pull to obtain a silica wet gel film.

[0045] The obtained wet gel film was placed in a closed container in the atmosphere of ethylene glycol methyl ether and dried naturally. The thickness of the obtained silica airgel film was 140nm, the transmittance was 89.7% ~ 96.0%, and the specif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com